Xa ukhetha iqonga elichanekileyo lezicelo zoshishino, izinto ezikhethiweyo zidlala indima ebalulekileyo ekumiseleni ukusebenza kunye neendleko. Iiqonga ezichanekileyo zegranite, iiqonga zesinyithi, kunye neeqonga zeseramikhi nganye ineenzuzo kunye neengxaki ezahlukeneyo, nto leyo eyenza ukuba zifaneleke kwizicelo ezahlukeneyo. Ngokwembono yeendleko, umahluko wamaxabiso phakathi kwezi zinto unokuphembelela kakhulu izigqibo zokuthenga, ingakumbi kumashishini apho ukuchaneka kubaluleke kakhulu.

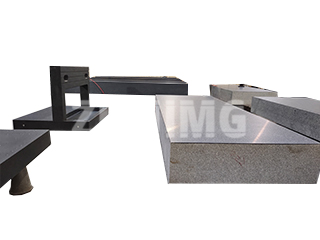

Amaqonga okuchaneka kwegranite athathwa ngokubanzi njengenye yezona ndlela zizinzileyo nezithembekileyo zokulinganisa ngokuchanekileyo kunye noomatshini. Igranite, ngakumbi i-ZHHIMG® Black Granite, yaziwa ngeempawu zayo ezibonakalayo ezibalaseleyo, kubandakanya uxinano lwayo oluphezulu, ukwanda okuphantsi kobushushu, kunye nokumelana nokuguguleka kunye nokuguquka. Inkqubo yokuvelisa amaqonga egranite iyinkimbinkimbi kwaye ifuna izixhobo eziphambili ukuze kufezekiswe amanqanaba aphezulu okuchaneka okufunekayo. Le nkqubo yokuvelisa inzima, kunye neempawu zezinto eziphezulu, yenza amaqonga egranite abe zezona zikhetho zibiza kakhulu kwezi zintathu. Nangona kunjalo, ukuqina kwawo ixesha elide, iimfuno ezincinci zokugcinwa, kunye nokuchaneka okungenakuthelekiswa nanto kubenza babe lukhetho olukhethwayo kumashishini afana ne-aerospace, imveliso ye-semiconductor, kunye nokulinganisa ngokuchanekileyo okuphezulu.

Amaqonga esinyithi esitshisiweyo, nangona enika uzinzo oluhle kunye nokuqina, ngokubanzi afikeleleka lula kuneeqonga zegranite. Isinyithi esitshisiweyo kulula ukusenza, kwaye izinto ngokwazo zibiza kancinci kunegranite okanye iseramikhi. Nangona isinyithi esitshisiweyo sibonelela ngenkxaso eyaneleyo kwizicelo ezininzi zoshishino, sinokwanda kakhulu kubushushu kwaye sisenokungagcini inqanaba elifanayo lokuchaneka ngokuhamba kwexesha njengeeqonga zegranite. Ke ngoko, amaqonga esinyithi esitshisiweyo adla ngokusetyenziswa kwiimeko apho iindleko zibaluleke kakhulu, kwaye iimfuno zokuchaneka azikho nzima kangako. Kwizicelo apho kukho imida yohlahlo-lwabiwo mali, amaqonga esinyithi esitshisiweyo lukhetho olufanelekileyo nolungabizi kakhulu, olubonelela ngokulinganisela okuhle kokusebenza kunye nexabiso.

Iiplatifomu zeseramikhi, ezenziwe ngezinto ezifana ne-alumina (Al₂O₃), i-silicon carbide (SiC), okanye i-silicon nitride (Si₃N₄), lolunye ukhetho olubonelela ngozinzo olugqwesileyo kunye nokuchaneka. Iiseramikhi zaziwa ngokuqina kwazo okuphezulu, ukumelana nokuguguleka, kunye nokwanda okuphantsi kobushushu, okwenza ukuba zilungele iindawo ezichanekileyo. Nangona kunjalo, inkqubo yokuvelisa iiplatifomu zeseramikhi ikhethekile kakhulu, kwaye izixhobo ngokwazo zihlala zibiza kakhulu kunesinyithi esityhidiweyo. Ngelixa iiplatifomu zeseramikhi zihlala zibonelela ngexabiso eliphakathi kwegranite kunye nesinyithi esityhidiweyo, zithathwa njengezingabizi kakhulu kunegranite kwizicelo ezininzi zokuchaneka, ngakumbi kumashishini afana nokuvelisa i-semiconductor, iinkqubo zokulinganisa ezibonakalayo, kunye ne-elektroniki yobuchwepheshe obuphezulu.

Ngokwembono yeendleko, uluhlu ludla ngokulandela olu landelelwano: Iiplatifomu zentsimbi ezikhazimlayo zezona zibiza kancinci, zilandelwe ziiplatifomu zeseramikhi, apho iiplatifomu zegranite Precision zezona zibiza kakhulu. Ukukhetha phakathi kwezi zinto kuxhomekeke kwiimfuno ezithile zesicelo, ezifana nenqanaba lokuchaneka okufunekayo, izinto ezingqongileyo, kunye nohlahlo lwabiwo-mali olukhoyo.

Kwimizi-mveliso efuna amanqanaba aphezulu okuchaneka, ukutyala imali kwigranite okanye kumaqonga e-ceramic kunokubonelela ngeenzuzo zexesha elide ngokubhekiselele ekusebenzeni nasekuqineni. Nangona kunjalo, kwizicelo apho ukusebenza kakuhle kweendleko kubaluleke kakhulu kwaye iimfuno zokuchaneka zingadingi kakhulu, amaqonga esinyithi abonelela ngesisombululo esisebenzayo ngaphandle kokubeka emngciphekweni ukusebenza kakhulu.

Ixesha leposi: Okthobha-23-2025