Kwihlabathi le-ultra-precision metrology, isixhobo sokulinganisa i-granite—njenge-surface plate, i-straightedge, okanye i-master square—sisixhobo esipheleleyo esicwangcisiweyo. Ezi zixhobo, ezigqitywe ngobuchule ngomatshini kwaye zinikezelwe ukugoba ngesandla, zixhomekeke ekuzinzeni nasekuchanekeni kwazo ngenxa yelitye eliqinileyo, elidala ngokwendalo ezenziwe ngalo. Nangona kunjalo, ubomi obude kunye nokuchaneka okugcinwe kwezi zixhobo zibalulekileyo akuqinisekisiwe; ziziphumo zeendawo ezilawulwayo kunye nezenzo zokusebenza ezicokisekileyo.

Kwi-ZHONGHUI Group (ZHHIMG®), siyaqonda ukuba nangona i-granite yethu enoxinano olukhulu inika isiseko esikhethekileyo, izinto ezininzi ezichaphazela ngqo ukuba isixhobo sokuchaneka sigcina ixesha elingakanani ukuchaneka kwaso okuqinisekisiweyo. Ukuqonda ezi zinto kubalulekile ekukhuseleni utyalo-mali lwakho.

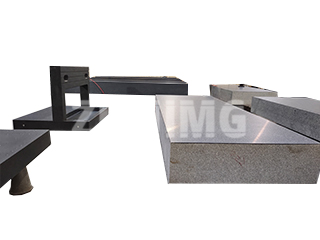

Iingongelo Eziphambili Zokuphila Ixesha Elide KweGranite

Ukonakala kweqonga lokulinganisa i-granite kudla ngokubangelwa kukuxinezeleka koomatshini kunye nokusingqongileyo kunokuba kubangelwa kukusilela kwezinto.

- Ukusasazwa komthwalo ngendlela engafanelekanga: Uxinzelelo olugqithisileyo okanye olungalinganiyo, ingakumbi xa lugxininiswe kwindawo enye yeqonga, lunokukhokelela ekugugeni kwendawo okanye ekuguqukeni okuncinci kwexesha elide. Oku kubonakala rhoqo xa izinto zokusebenza ezinzima zibekwa ngokuphindaphindiweyo kwindawo enye, nto leyo ebangela ukuba umphezulu wokusebenza wecandelo ulahlekelwe bubuthambile bawo obufanelekileyo.

- Ungcoliseko lweNdalo: Itshiphu enye, ukucheba ngesinyithi, okanye isuntswana lothuli olurhabaxa zinokusebenza njengephepha lesihlabathi phakathi kwegranite kunye nesixhobo sokusebenza. Indawo yokusebenza engcolileyo ayizisi nje kuphela iimpazamo zokulinganisa kodwa ikhawulezisa kakhulu ukuguguleka komphezulu wegranite, inciphisa ngokuthe ngqo ubomi bayo obuchanekileyo benkonzo.

- Izinto Zokusebenza Nomgangatho Womphezulu: Ukwakheka kunye nokugqitywa kwezinto ezilinganiswayo kudlala indima ebalulekileyo kumazinga okuguguleka. Izinto ezithambileyo ezifana nobhedu kunye ne-aluminium zibangela ukuguguleka okuncinci, ngelixa izinto eziqinileyo, ngakumbi isinyithi esenziwe ngomthi, zinokubangela ukuba i-granite iguguleke kakhulu. Ngaphezu koko, izinto zokusebenza ezinoburhabaxa bomphezulu (ukugqitywa okurhabaxa) zinokuthanda ukukrwela iqonga le-granite eligobileyo kakuhle, oko konakalisa i-reference plane ngokusisigxina.

- Ukusetyenziswa Kakubi Kokusebenza Nokuchukumisa Okurhabaxa: Ubulukhuni obuphantsi bomphezulu wegranite, nangona buluncedo kwiimpawu zayo ezingezizo zemagnethi nezingezona ezomileyo, buyenza ibe sesichengeni sokuguguleka ngenxa yokungqubana. Iindlela ezinje ngokuhamba ngokugqithisileyo kwesixhobo somsebenzi okanye isixhobo sokubhekisa kumphezulu—endaweni yokuphakamisa nokubeka—zizisa ukungqubana okonakalisa ngokukhawuleza umaleko ophezulu wegranite. Oku kuqinisekisa umthetho: izixhobo zokulinganisa igranite zizixhobo, kungekhona iibhentshi zomsebenzi.

Ukuvelisa ngokuchanekileyo: Igunya loomatshini abancedisayo

Ukudalwa kwesixhobo sokulinganisa i-granite esisemgangathweni ophezulu nesichanekileyo kuxhomekeke kakhulu ekuchanekeni koomatshini bokulungisa abancedisayo njengoko kunjalo nakwilitye ngokwalo.

Ukuqinisekisa ukuchaneka kobukhulu bemveliso yokugqibela, yonke into esetyenziswa kumatshini wokucubungula amatye kufuneka igcinwe ngokwemigangatho ye-metrology. Oku kufuna ukujongwa ngokuphindaphindiweyo kobukhulu bokuhlanganiswa komatshini kunye nokuthotyelwa ngokungqongqo kweendlela zobugcisa zokucoca amatye. Ngaphambi kokuba kuqalwe nakuphi na ukusetyenzwa kwamatye ngokusesikweni, izixhobo kufuneka zivavanywe ukuqinisekisa ukusebenza okuqhelekileyo. Ukusebenza komatshini ongalunganga akugcini nje ngokuba yingozi kodwa kunokukhokelela ekulahlekelweni kwezinto ezixabisekileyo zegranite ezikhethiweyo.

Ukugcina izinto zangaphakathi zomatshini—ukusuka kwibhokisi yespindle ukuya kwiindlela zokuphakamisa—kubalulekile. Ukuthambisa kufuneka kusetyenziswe ngokuchanekileyo kuzo zonke iindawo zokudibana, kuquka iibheringi kunye neendibano zezikrufu zelothe, ngaphambi kokuba kusebenze naluphi na uhlobo. Uqhagamshelo kufuneka lungabi nazimpawu okanye amaqhuma, kwaye naluphi na ugqwala lwangaphakathi okanye ungcoliseko kufuneka lucocwe ngononophelo kwaye luphathwe nge-anti-rust coating ukuthintela izinto zangaphandle ukuba zingayibeki emngciphekweni inkqubo yokusila.

Indima Ebalulekileyo Yomgangatho Wokuhlanganiswa KweeMechanical

Umgangatho woomatshini abasetyenziselwa ukucubungula i-granite unxulumene ngokuthe ngqo nokuzinza kwemveliso yokugqibela ye-granite. Oku kufuna ingqalelo engqongqo kwiinkcukacha zokuhlanganiswa koomatshini:

- Ukunyaniseka kweBearing kunye neSeal: Iibheringi mazicocwe kakuhle ukuze kususwe izinto ezilwa nomhlwa kwaye zihlolwe ukuba zijikelezwe kakuhle na ngaphambi kokuba zihlanganiswe. Amandla asetyenziswayo ngexesha lokufakwa kweebheringi kufuneka alingane, alingane, kwaye afaneleke, kuthintelwe uxinzelelo kwiindlela zomdyarho kwaye kuqinisekiswe ukuba ubuso bokugqibela buthe nkqo kwishaft. IiSeal mazicinezelwe ngaxeshanye kwiigrooves zazo ukuthintela ukujija, okuya kungenisa ukudlala kunye nokungazinzi kumatshini wokucubungula.

- Ukulungelelaniswa kweeNkqubo zokuHamba: Kwizinto ezifana neenkqubo ze-pulley, ii-axes kufuneka zihambelane ngokugqibeleleyo kwaye zilungelelaniswe ukuthintela uxinezeleko olungalinganiyo, ukutyibilika kwebhanti, kunye nokuguguleka okukhawulezileyo—konke oku kukhokelela ekungcangcazeleni okuphazamisa ukugoba ngokuchanekileyo kwe-granite. Ngokufanayo, ukuthamba kunye nokudibana kwenyani kwemiphezulu yokutshatisa kwiikhonkco zomatshini kufuneka kuqinisekiswe kwaye kulungiswe ukuba kukho naluphi na uguquko okanye ii-burrs ezifunyenweyo.

Ngamafutshane, isixhobo sokulinganisa igranite sisixhobo esihlala ixesha elide kodwa esilungiswe kakuhle. Ubomi baso obugqwesileyo buyimveliso yegranite emnyama ye-ZHHIMG® ekumgangatho ophezulu, edibene nolawulo olungqongqo lokucoceka kokusebenza, ukuphathwa kakuhle kwezixhobo zomsebenzi, kunye nokugcinwa ngononophelo koomatshini abachanekileyo okusifikisa kuchanekileyo lokugqibela noluqinisekisiweyo.

Ixesha leposi: Oktobha-30-2025