Kwiminyaka yakutshanje, uluntu lwe-industrial metrology luqalise ukunikela ingqalelo ngakumbi kwisici esibonakala sincinci se-granite precision surface plates: i-edge chamfering. Nangona ukuba tyaba, ubukhulu, kunye nomthamo womthwalo bezisoloko ziphambili kwiingxoxo, iingcali ngoku zigxininisa ukuba imiphetho yezi zixhobo zichanekileyo kakhulu inokuchaphazela kakhulu ukhuseleko, ukuqina, kunye nokusetyenziswa.

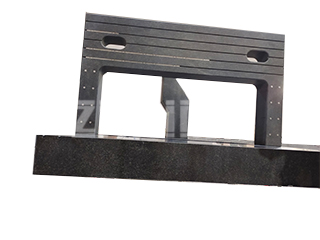

Iipleyiti zomphezulu ezichanekileyo zegranite zisebenza njengomqolo wokulinganisa kwemizi-mveliso, zibonelela ngendawo yokubhekisa ezinzileyo nechanekileyo. Imiphetho yezi pleyiti, ukuba ishiywe ibukhali, ibeka umngcipheko ngexesha lokuphathwa nokuthuthwa. Iingxelo ezivela kwiindawo ezahlukeneyo zokusebenzela ukuvelisa zibonisa ukuba imiphetho enemiphetho emincinci—iikona ezincinci ezibhityileyo okanye ezijikelezileyo—zincede ekunciphiseni iingozi nokunciphisa umonakalo kwiipleyiti ngokwazo.

Iingcali zoshishino ziphawula ukuba ukutshaya i-chamfering kungaphezulu nje komlinganiselo wokhuseleko. “Umphetho otshaya i-chamfering ukhusela ukuthembeka kwe-granite,” utshilo injineli ephambili ye-metrology. “Kwane-chip encinci yekona inokubeka ubomi bepleyiti emngciphekweni, kwaye kwizicelo ezichanekileyo, inokuchaphazela ukuthembeka kokulinganisa.”

Iinkcukacha eziqhelekileyo ze-chamfer, ezifana ne-R2 kunye ne-R3, ngoku ziqhelekile kwiindawo ezininzi zokusebenzela. I-R2 ibhekisa kwi-radius eyi-2mm ecaleni komphetho, edla ngokusetyenziswa kwiipleyiti ezincinci okanye ezo zisetyenziswa kwiindawo eziphantsi kokunyakaza. I-R3, i-radius eyi-3mm, ikhethwa kwiipleyiti ezinkulu nezinzima eziphathwa rhoqo. Iingcali zicebisa ukukhetha ubungakanani be-chamfer ngokusekelwe kubukhulu bepleyiti, amaxesha okuphatha, kunye neemfuno zokhuseleko kwindawo yokusebenza.

Uphando lwakutshanje kwiilabhoratri zoshishino lubonisa ukuba iipleyiti ezineemiphetho ezigobileyo azinamonakalo ungako ngengozi kwaye azinazo iindleko zokulungisa ezifunekayo. Ngaphaya kokuqina, imiphetho egobileyo ikwaphucula i-ergonomics ngexesha lokuphakamisa nokufakela, ukuqinisekisa ukuhamba kakuhle kwemisebenzi kwimigca yemveliso exakekileyo.

Amagunya okhuseleko aqalise ukufaka izikhokelo ze-chamfer kwimigangatho yangaphakathi. Kwiifektri ezininzi zaseYurophu naseMntla Melika, imiphetho ye-chamfered ngoku yindlela ecetyiswayo kuzo zonke iipleyiti zomphezulu we-granite ezidlula ubungakanani obuthile.

Nangona abanye besenokucinga ukuba i-edge chamfering yinto encinci, abavelisi bagxininisa ukubaluleka kwayo okukhulayo kwi-metrology yanamhlanje. Njengoko iinkqubo zoshishino zifuna ukuchaneka nokusebenza kakuhle, ingqalelo kwiimpawu ezifana ne-edge chamfers inokwenza umahluko olinganisekayo.

Abahlalutyi baqikelela ukuba njengoko ishishini le-metrology liqhubeka nokutshintsha, ingxoxo ejikeleze imiphetho yeepleyiti iya kukhula. Uphando lubonisa ukuba ukudibanisa imiphetho ene-chamfered kunye nezinye iimpawu zokukhusela, ezifana nezixhobo zokuphatha ezifanelekileyo kunye nezixhasi zokugcina, kunegalelo elikhulu ekuqhubekeni kwexesha elide kunye nokuthembeka kweepleyiti zegranite.

Ukuqukumbela, i-chamfering—eyayikade iyinto encinci—ivele njengophawu oluphambili loyilo ekuvelisweni nasekugcinweni kweepleyiti zomphezulu wegranite. Nokuba ukhetha i-chamfer ye-R2 okanye ye-R3, abasebenzisi bemizi-mveliso bafumanisa ukuba ukulungiswa okuncinci kunokubonelela ngeenzuzo ezibonakalayo kukhuseleko, ukuqina, kunye nokusebenza kakuhle.

Ixesha leposi: Sep-25-2025