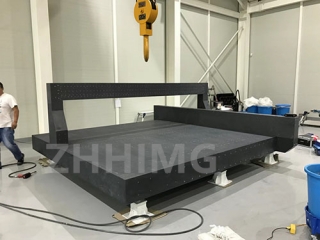

Kwiworkshop yokwenziwa kwee-semiconductor, iimfuno zenkqubo yokwenziwa kwee-chip kwiimeko zokusingqongileyo kunye nokuchaneka kwezixhobo zigqithisile, kwaye naluphi na utshintsho oluncinci lunokukhokelela ekwehleni okukhulu kwesivuno see-chip. Iqonga lokuhamba kwe-gantry yokuchaneka kwe-XYZT lixhomekeke kwizixhobo ze-granite ukuze zisebenzisane nezinye iindawo zeqonga ukwakha isiseko esiqinileyo sokufezekisa ukuchaneka kwe-nanoscale.

Iipropati ezibalaseleyo zokuthintela ukungcangcazela

Kwindawo yokusebenzela yokuvelisa i-semiconductor, ukusebenza kwezixhobo ezingaphandle kunye nabasebenzi abahambahambayo kunokubangela ukungcangcazela. Ulwakhiwo lwangaphakathi lwezixhobo zegranite luxinene kwaye lufana, luneempawu zendalo eziphezulu zokudambisa, njenge "vibration" esebenzayo yokungcangcazela. Xa ukungcangcazela kwangaphandle kudluliselwa kwiqonga le-XYZT, icandelo legranite linokunciphisa ngokufanelekileyo amandla okungcangcazela angaphezu kwama-80% kwaye linciphise ukuphazamiseka kokungcangcazela ekuchanekeni kokunyakaza kweqonga. Kwangaxeshanye, iqonga lixhotyiswe ngenkqubo yesikhokelo sokungcangcazela komoya echanekileyo, esebenza kunye nezixhobo zegranite. Isikhokelo sokungcangcazela komoya sisebenzisa ifilimu yegesi ezinzileyo eyenziwe yigesi yoxinzelelo oluphezulu ukuze kufezekiswe intshukumo yokuxhoma engenakuthintana yeendawo ezihambayo zeqonga kwaye kuncitshiswe ukungcangcazela okuncinci okubangelwa kukungqubana koomatshini. Kunye, bobabini baqinisekisa ukuba ukuchaneka kokubeka iqonga kuhlala kugcinwa kwinqanaba le-nanometer kwiinkqubo eziphambili ezifana ne-chip lithography kunye nokukrola, kwaye kuphephe ukuphambuka kweepatheni zesekethe ze-chip ezibangelwa kukungcangcazela.

Uzinzo oluhle kakhulu lobushushu

Ukutshintshatshintsha kobushushu kunye nokufuma kwindawo yokusebenzela kunempembelelo enkulu ekuchanekeni kwezixhobo zokwenza iitshiphusi. I-coefficient yokwandisa ubushushu yegranite iphantsi kakhulu, ngokubanzi kwi-5-7 × 10⁻⁶/℃, ubukhulu abutshintshi xa ubushushu butshintsha. Nokuba umahluko wobushushu phakathi kwemini nobusuku kwindawo yokusebenzela okanye ukuveliswa kobushushu kwezixhobo kubangela ukuba ubushushu obuphakathi butshintshe, izinto zegranite zinokuhlala zizinzile ukuthintela ukuguquka kweqonga ngenxa yokwanda nokuncipha kobushushu. Kwangaxeshanye, inkqubo yokulawula ubushushu ekrelekrele exhotyiswe ngeqonga ijonga ubushushu obuphakathi ngexesha langempela, ilungisa ngokuzenzekelayo izixhobo zokupholisa umoya kunye nokusasaza ubushushu, kwaye igcina ubushushu bendawo yokusebenzela kwi-20 ° C ±1 ° C. Idityaniswe neenzuzo zokuzinza kobushushu begranite, qinisekisa ukuba iqonga elisebenza ixesha elide, ukuchaneka kokuhamba kwe-axis nganye kuhlala kuhlangabezana nemigangatho yokuchaneka kwe-nanometer yokuvelisa iitshiphusi, ukuqinisekisa ukuba ubungakanani bepateni ye-chip lithography ichanekile, ubunzulu bokukrola buyafana.

Ukuhlangabezana neemfuno zokusingqongileyo okucocekileyo

Ivenkile yokuvelisa ii-semiconductor kufuneka igcine ucoceko oluphezulu ukuthintela amasuntswana othuli ukuba angangcolisi i-chip. Izinto ze-granite ngokwazo azivelisi uthuli, kwaye umphezulu uthambile, akukho lula ukuwufunxa uthuli. Iqonga lilonke lisebenzisa uyilo lwesakhiwo oluvaliweyo ngokupheleleyo okanye oluvaliweyo ukuze kuncitshiswe ukungena kothuli lwangaphandle. Inkqubo yokujikeleza komoya wangaphakathi iqhagamshelwe nenkqubo yomoya ococekileyo we-workshop ukuqinisekisa ukuba ucoceko lomoya wangaphakathi lufikelela kwinqanaba elifunekayo xa kusenziwa ii-chip. Kule ndawo icocekileyo, izinto ze-granite aziyi kuchaphazela ukusebenza ngenxa yokukhukuliseka kothuli, kwaye izinto eziphambili ezifana nezinzwa ezichanekileyo kunye nee-motor zeqonga nazo zinokusebenza ngokuzinzileyo, zibonelela ngesiqinisekiso sokuchaneka kwe-nanoscale okuqhubekayo nokuthembekileyo kokwenziwa kwee-chip, kwaye zincede ishishini le-semiconductor ukuba litshintshele kwinqanaba lenkqubo ephezulu.

Ixesha leposi: Epreli-14-2025