Ishishini lokucubungula ukutya kunye nokupakisha lixhomekeke kwisiseko sokuchaneka okungaguqukiyo. Yonke into, ukusuka kwi-nozzle ye-filler ekhawulezayo ukuya kwindlela yokutywina eyinkimbinkimbi, kufuneka ihlangabezane nokunyamezelana okuqinileyo ukuqinisekisa umgangatho wemveliso, ukunciphisa inkunkuma, kwaye—okubaluleke kakhulu—kuqinisekise ukhuseleko lwabathengi. Oku kuphakamisa umbuzo osisiseko kwiingcali zolawulo lomgangatho: Ngaba iqonga le-granite elichanekileyo lifanelekile ukuhlolwa kwento kwimishini yokutya, kwaye idlala yiphi indima iimfuno zococeko?

Impendulo ithi ewe, i-precision granite ifanelekile kakhulu ekuhlolweni kobukhulu bezixhobo zoomatshini bokutya, kodwa indawo esetyenziswa kuyo ifuna ukuqwalaselwa ngononophelo kwemigangatho yococeko.

Ityala leGranite kwi-Food-Grade Precision

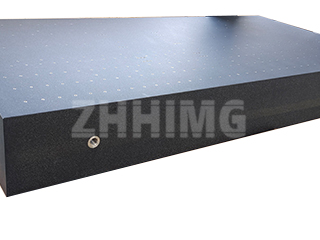

Eyona nto iphambili kuyo, igranite yeyona nto ikhethwayo kwi-metrology ngenxa yeempawu zayo ezisisiseko, ezihambelana kakuhle nemigaqo emininzi yococeko olungenakudibana nokutya. Igranite emnyama egqwesileyo ye-ZHHIMG®, enoxinano oluphezulu kunye nokwanda kobushushu obuphantsi, inika umlinganiselo wokulinganisa apho isinyithi esenziwe ngentsimbi okanye intsimbi engatyiwayo ingenakukwazi ukulingana. Ibonelela:

- Uzinzo Lwemilinganiselo: I-Granite ayinamagnethi kwaye imelana kakhulu nomhlwa kunye nokugqwala, izinto eziphambili eziluncedo kwiindawo ezinomswakama ophezulu okanye imijikelo yokuhlamba rhoqo.

- Ukungangcolisi: Ngokungafaniyo neentsimbi, i-granite ayifuni ii-oyile ezithintela ukugqwala kwaye ayingcolisi ngokwemvelo. Ayiyi kusebenzisana nezinto zokucoca eziqhelekileyo okanye iintsalela ezinxulumene nokutya, ukuba nje umphezulu ugcinwe kakuhle.

- Ubukhulu Bokuthe Tye: Amaqonga ethu, afikelela kwinqanaba le-nanometer lokuthe tye kunye nokunamathela kwimigangatho efana ne-ASME B89.3.7, abalulekile ekuhloleni izinto ezifana neeblade zokusika ngokuchanekileyo, ii-conveyor alignment rails, kunye nee-sealing dies—iindawo apho ukuchaneka kwe-micron kulawula ukhuseleko lokutya kunye nokusebenza kakuhle.

Ukuhambahamba kwiSimiselo soYilo loCoceko

Nangona ipleyiti yomphezulu wegranite ngokwayo idla ngokusetyenziswa kwilabhoratri yomgangatho owahlukileyo okanye kwindawo yokuhlola, inkqubo yokuhlola ixhasa ukuthotyelwa kwezikhokelo zococeko ezifana nezo zimiselwe yi-3-A Sanitary Standards okanye i-European Hygienic Engineering & Design Group (EHEDG).

Ingxaki ebalulekileyo yococeko kuyo nayiphi na isixhobo sokuhlola ixhomekeke kwimigaqo emibini: ukucoceka nokungagcini iintsholongwane. Ukuze i-granite echanekileyo kwindawo ekufutshane nokutya ifumaneke, oku kuthetha ukuba kukho iindlela ezingqongqo kumsebenzisi wokugqibela:

- Umphezulu Ongenazimbobo: I-granite ecolekileyo ye-ZHHIMG ayinazimbobo ngokwemvelo. Nangona kunjalo, ukunamathela kwiindlela zokucoca ezingqongqo kunye nezicoci ezifanelekileyo zemizi-mveliso ezingena-asidi kubalulekile ukuthintela naluphi na ukungcola okanye ukwakheka kwentsalela encinci.

- Ukuphepha Ukudibana: Iqonga legranite akufuneki lisetyenziswe njengendawo yokusebenza ngokubanzi. Iiasidi ezivela ekuchithekeni kokutya/kweziselo ezithile zinokugrumba umphezulu, zenze iindawo ezincinci zokungcola.

- Uyilo lweCandelo eliNcedisayo: Ukuba iqonga legranite lifuna isitendi esiqhotyoshelweyo okanye izixhobo ezincedisayo (ezifana neejigi okanye izixhobo), ezi zinto zesinyithi kufuneka zenzelwe iindawo ezicocekileyo—oko kuthetha ukuba kufuneka zisuswe ngokulula, zigudiswe, zingafunxi, kwaye zingabi namingxunya okanye imibhobho engenanto apho umswakama okanye iintsholongwane zinokuqokelelana khona.

Ukuqukumbela, amaqonga e-precision granite ayimpahla exabisekileyo kulawulo lomgangatho woomatshini bokutya, esebenza njengesalathiso esithembekileyo esiqinisekisa amandla oomatshini okusebenza ngokukhuselekileyo nangokufanelekileyo. Indima ye-ZHHIMG, njengomvelisi oqinisekisiweyo (i-ISO 9001 kunye nomgangatho we-metrology ohambelanayo), kukubonelela ngeqonga lokuchaneka okungathandabuzekiyo, okuvumela abathengi bethu boomatshini bokutya ukuba baqinisekise ngokuzithemba ukuba izinto zabo—kwaye ekugqibeleni, iimveliso zabo—zihlangabezana nomgangatho wehlabathi wokhuseleko nokuchaneka.

Ixesha lokuthumela: Okthobha-22-2025