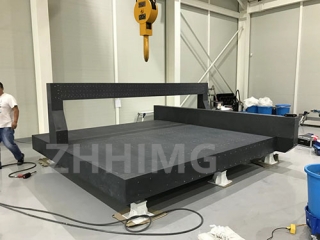

IKwishishini lokuvelisa i-semiconductor, ukuchaneka kwezixhobo zokuhlola i-wafer kubalulekile ukuqinisekisa umgangatho weesekethe ezidibeneyo. Iziseko zoomatshini be-granite ezichanekileyo kakhulu, ezifana nezo zibonelelwa yi-ZHHIMG®, zidlala indima ebalulekileyo ekuphuculeni ukusebenza kwezixhobo ezinjalo. Nantsi indlela ezenza ngayo umahluko.

I-Exceptional Dimensional StabilityGranite ine-coefficient yokwandisa ubushushu ephantsi kakhulu, malunga ne-(4–8)×10⁻⁶/℃, ephantsi kakhulu kuneentsimbi ezininzi. Kwimeko elawulwa ngokuqinileyo yeefektri ze-semiconductor, apho nokuguquguquka okuncinci kobushushu kunokubangela iimpazamo zokulinganisa, iziseko zomatshini we-granite zihlala zizinzile. Olu zinzo luqinisekisa ukuba indawo yezixhobo kwizixhobo zokuhlola i-wafer ihlala ichanekile, ithintela naluphi na uphambuko olubangelwa bubushushu olunokuchaphazela ukuchaneka kweziphumo zovavanyo.

Ukudambisa ukungcangcazela okuphezuluImigangatho yemveliso idla ngokuzaliswa kukungcangcazela okuvela kwimithombo eyahlukeneyo. Iimpawu zokudambisa ezifumaneka kwigranite, ezinomlinganiselo wokudambisa we-0.05–0.1, zifunxa kwaye zisuse ngempumelelo ezi ngcangcazelo. Kwi-wafer insp

i-ection, efuna imifanekiso enesisombululo esiphezulu kunye nokufundwa kwe-sensor ngokuchanekileyo, ukunciphisa ukungcangcazela okunikezelwa ziziseko ze-granite kubaluleke kakhulu. Kunciphisa ukuphazamiseka okunokufiphalisa imifanekiso okanye kutshintshe idatha ye-sensor, okuvumela izixhobo ukuba zibambe ulwazi olucacileyo noluchanekileyo malunga nomphezulu we-wafer kunye nesakhiwo sangaphakathi.

Ukuqina Okuphezulu Nokumelana NokunxibaNgexinano olumalunga ne-3100 kg/m³, iziseko zomatshini zegranite zeZHHIMG® zibonelela ngokuqina okumangalisayo. Zinokuxhasa izixhobo ezinzima zezixhobo zokuhlola i-wafer ngaphandle kokuguquka, zigcina ulungelelwaniso lweenkqubo ze-optical kunye ne-mechanical. Ukongeza, ubunzima obuphezulu begranite (isikali seMohs 6–7) kunye nokumelana nokunxiba okugqwesileyo kuqinisekisa ukuba umphezulu wesiseko somatshini uhlala uthe tyaba kwaye uthambile ngokuhamba kwexesha. Olu lungelelwaniso lubalulekile ekuchanekeni kwexesha elide, njengoko naluphi na ukuguga okanye ukuguqulwa kwisiseko kunokuthoba kancinci ukuchaneka kwesixhobo.

Ukungasebenzi Kwekhemikhali Ukwenziwa kwee-semiconductor kubandakanya ukuvezwa kwiikhemikhali ezahlukeneyo. Ukungasebenzi kweekhemikhali zegranite kuyenza imelane nokugqwala kwezi zinto. Le propati ikhusela ukuthembeka kwesiseko somatshini, ithintela umonakalo obangelwa ziikhemikhali onokuchaphazela uzinzo kunye nokuchaneka kwezixhobo zokuhlola.

Ukuqukumbela, iziseko zomatshini wegranite ezichanekileyo aziyonto nje kuphela kodwa zizinto ezibalulekileyo ezinceda ekufezekiseni iimfuno zokuchaneka okuchanekileyo kwezixhobo zokuhlola i-wafer. Xa ukhetha iziseko zomatshini wegranite, khetha ababoneleli abathembekileyo abanjengoZHHIMG®. Ngeziqinisekiso ezininzi kunye nokuzibophelela kumgangatho, iZHHIMG® iqinisekisa ukuba isiseko ngasinye somatshini wegranite sinikezela ukuthembeka kunye nokusebenza okufunekayo kwimveliso ye-semiconductor ephucukileyo.

Ixesha lokuthumela: Juni-03-2025