Kwimveliso echanekileyo kakhulu kunye ne-metrology, i-granite slab sisiseko esingenakuphikiswa—isalathiso se-zero-point sokulinganisa ubukhulu. Ukukwazi kwayo ukubamba iplane ephantse igqibelele akusiyo nje into yendalo, kodwa sisiphumo senkqubo yokubumba elawulwa ngononophelo, elandelwa kukugcinwa okucwangcisiweyo nokuqhelekileyo. Kodwa luluphi uhambo oluqinisekileyo oluthathwa yi-granite slab ukuze ifikelele kugqibelelo olunjalo, kwaye zeziphi iindlela ezifunekayo ukuze iqhubeke? Kwiinjineli kunye nabaphathi bomgangatho, ukuqonda zombini imvelaphi yale ngcaciso kunye namanyathelo afunekayo okugcina le mveliso kubaluleke kakhulu ekugcineni umgangatho wokuvelisa.

Icandelo 1: Inkqubo yokuBumba—UbuNjineli bokuThafa

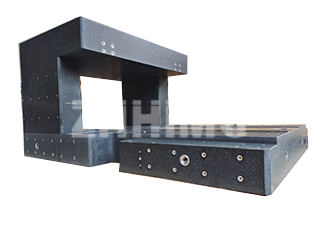

Uhambo lweslab yegranite, ukusuka kwibhloko eqingqiweyo ukuya kwipleyiti yomphezulu ekumgangatho wereferensi, lubandakanya uthotho lwamanqanaba okusila, ukuzinzisa, kunye nokugqiba, ngalinye lenzelwe ukunciphisa kancinci kancinci impazamo yobukhulu.

Ekuqaleni, emva kokusikwa, i-slab ifakwa kwi-Rough Shaping and Grinding. Eli nqanaba lisusa izinto ezininzi ukuze kuqinisekiswe ukuba i-geometry yokugqibela ilungile kwaye i-rough flatness ilungile. Okubaluleke kakhulu, le nkqubo ikwanceda ekukhululeni uninzi loxinzelelo olusele oluhlala kwilitye ngexesha lokumba kunye nokusika kokuqala. Ngokuvumela i-slab ukuba "ihlale" kwaye izinze kwakhona emva kwenyathelo ngalinye lokususa izinto ezinkulu, sithintela ukushukuma kobukhulu bexesha elizayo, siqinisekisa uzinzo lwexesha elide.

Utshintsho lokwenyani lwenzeka ngexesha le-The Art of Precision Lapping. Ukulepha yinkqubo yokugqibela, ekhethekileyo kakhulu ecoca umphezulu othe tyaba ube yiplani yesalathiso eqinisekisiweyo. Oku akukokugaywa ngoomatshini; ngumsebenzi ocokisekileyo, okhawulezayo, noxinzelelo oluphezulu. Sisebenzisa iikhompawundi ezithambileyo nezikhululekileyo—ezidla ngokuba yidayimani—ezixhonywe kwindawo yolwelo, ezisetyenziswa phakathi komphezulu wegranite kunye nepleyiti yokulepha yesinyithi eqinileyo. Intshukumo ilawulwa ngononophelo ukuqinisekisa ukususwa kwezinto ezifanayo kumphezulu. Esi siphumo sokulinganisa, esiphindaphindwa ngesandla nangoomatshini kumanyathelo aphindaphindwayo, sicoca kancinci ukuba tyaba ngaphakathi kwee-microns okanye nakwii-sub-microns (ukuhlangabezana nemigangatho eqinileyo efana ne-ASME B89.3.7 okanye i-ISO 8512). Ukuchaneka okufunyenweyo apha akuphelelanga malunga nomatshini kodwa kungaphezulu malunga nobuchule bomqhubi, esibujonga njengomsebenzi obalulekileyo, ongenakutshintshwa.

Icandelo 2: Ukugcinwa—Isitshixo Sokuchaneka Okuhlala Kuhleli

Ipleyiti yomphezulu wegranite sisixhobo sokuchaneka, asiyobhentshi yokusebenzela. Nje ukuba iqinisekiswe, amandla ayo okugcina ukuchaneka axhomekeke ngokupheleleyo kwiindlela zomsebenzisi kunye nokusingqongileyo.

Ulawulo lweNdalo yeyona nto iphambili echaphazela ukuchaneka kwegranite. Nangona igranite ine-coefficient ephantsi yokwandiswa kobushushu (COE), umahluko wobushushu phakathi komphezulu ophezulu nosezantsi (i-gradient yobushushu ethe nkqo) unokubangela ukuba i-slab yonke igobe okanye igobe kancinci. Ke ngoko, ipleyiti kufuneka igcinwe kude nelanga elithe ngqo, ii-air conditioner drafts, kunye nemithombo yobushushu egqithisileyo. Indawo efanelekileyo igcina i-68°F ± 1°F (20℃ ± 0.5℃) ezinzileyo.

Ngokuphathelele iProtokholi yoSetyenziso noCoca, ukusetyenziswa rhoqo kwendawo kubangela ukuguguleka okungalinganiyo. Ukuze kuliwe noku, sicebisa ukuba i-slab ijikeleziswe rhoqo kwindawo yayo kwaye isasazwe umsebenzi wokulinganisa kuyo yonke indawo. Ukucoca rhoqo kuyimfuneko. Uthuli kunye nenkunkuma encinci zisebenza njengezinto ezirhabaxa, zikhawulezisa ukuguguleka. Kufuneka kusetyenziswe kuphela izicoci zegranite ezikhethekileyo, okanye i-isopropyl alcohol ecocekileyo kakhulu. Ungaze usebenzise izicoci zasekhaya okanye izicoci ezisekelwe emanzini ezinokushiya intsalela enamathelayo okanye, kwimeko yamanzi, zipholile okwethutyana kwaye ziphazamise umphezulu. Xa ipleyiti ingasebenzi, kufuneka igqunywe ngesigqubuthelo esicocekileyo, esithambileyo, esingarhawuzeliyo.

Okokugqibela, malunga noHlaziyo kunye noHlaziyo, nokuba kunyanyekelwa kakuhle, ukuguguleka akunakuphepheka. Ngokuxhomekeke kwinqanaba lokusetyenziswa (umz., iBanga AA, A, okanye B) kunye nomsebenzi, ipleyiti yomphezulu wegranite kufuneka ihlengahlengiswe ngokusesikweni rhoqo kwiinyanga ezi-6 ukuya kwezingama-36. Ingcali eqinisekisiweyo isebenzisa izixhobo ezifana nee-autocollimators okanye ii-laser interferometers ukulinganisa ukuphambuka komphezulu. Ukuba ipleyiti iwela ngaphandle kwebanga layo lokunyamezela, i-ZHHIMG inikezela ngeenkonzo zobuchwephesha zokuphinda idibanise. Le nkqubo ibandakanya ukubuyisela umgca ochanekileyo kwindawo okanye kwiziko lethu ukuze sibuyisele ngobunono ubunzulu obuqinisekisiweyo bokuqala, siphinde sibuyisele ubomi besixhobo ngokufanelekileyo.

Ngokuqonda inkqubo yokubumba ebaluleke kakhulu kunye nokuzibophelela kwishedyuli yokulungisa engqongqo, abasebenzisi banokuqinisekisa ukuba iipleyiti zabo zomphezulu wegranite zihlala zisisiseko esithembekileyo kuzo zonke iimfuno zabo zomgangatho ochanekileyo, iminyaka ngeminyaka.

Ixesha leposi: Oktobha-24-2025