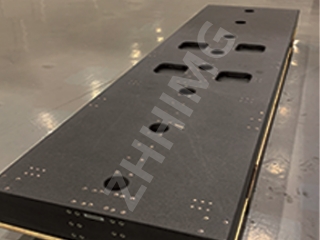

I-Granite yinto ethandwayo esetyenziswa kwinkqubo yokwenziwa kwezixhobo zokubeka i-optical waveguide ngenxa yozinzo lwayo oluphezulu, ukuqina kwayo, kunye nokumelana nokuguquguquka kwayo. I-granite assembly isetyenziswa kakhulu ekwakheni izixhobo zokubeka i-optical waveguide ngenxa yokuqina kwayo, okuqinisekisa ukuba isixhobo sihlala sizinzile ngexesha lokusetyenziswa kwaye asonakali lula.

Kweli nqaku, siza kuxoxa ngendlela yokusebenzisa nokugcina indibano yegranite kwisixhobo sakho sokubeka i-optical waveguide. Ezi ngcebiso ziya kukunceda ugcine isixhobo sakho sisebenza kakuhle, sandise ixesha laso lokuphelelwa, kwaye siphucule ukuchaneka kwaso.

1. Ukuphathwa kunye nokufakwa

Inyathelo lokuqala ekusebenziseni i-granite assembly kwisixhobo sakho sokubeka i-optical waveguide kukuphatha nokufakela ngokufanelekileyo. Xa uphatha i-granite assembly, kubalulekile ukuba ungayingqubani okanye uyiwise. Soloko uphatha i-granite assembly ngokuqinileyo, njengoko nawuphi na umonakalo unokuchaphazela ukuchaneka kwesixhobo.

Xa ufaka isixhobo sokubeka i-optical waveguide, qiniseka ukuba i-granite assembly ilungile kwaye izinzile. Oku kuya kuqinisekisa ukuba ukuchaneka kwesixhobo kugcinwa ixesha elide.

2. Ukucoca

Ukucoca indibano yegranite rhoqo kubalulekile ukuqinisekisa ukuba umphezulu uhlala uthambile kwaye ungenaluthuli okanye inkunkuma. Kufuneka usebenzise ilaphu elithambileyo okanye ibrashi ukususa naluphi na uthuli okanye inkunkuma kumphezulu wendibano yegranite. Ibrashi ethambileyo okanye ilaphu liya kuthintela nayiphi na imikrwelo okanye omnye umonakalo kwindibano yegranite.

Xa ucoca indibano yegranite, kuphephe ukusebenzisa iikhemikhali ezirhabaxa okanye ezirhabaxa kuba oku kungonakalisa ukugqitywa okukhazimlisiweyo. Endaweni yoko, sebenzisa isepha ethambileyo namanzi afudumeleyo ukucoca umphezulu wendibano yegranite. Emva kokuhlamba, hlambulula umphezulu ngamanzi acocekileyo uze uwomise ngelaphu elithambileyo.

3. Ulondolozo

Ukugcinwa kwendibano yakho yegranite kubalulekile ukuqinisekisa ukuba isixhobo sakho sokubeka i-optical waveguide sihlala ixesha elide. Ukuhlolwa rhoqo kokugcinwa kunokunceda ekufumaneni naziphi na iingxaki ezinokubakho ngaphambi kokuba zibe yingxaki enkulu. Jonga iimpawu zokuguguleka, ezinje ngokuqhekeka, iitships, okanye iimbobo, kumphezulu wendibano yegranite. Nawuphi na umonakalo kumphezulu wendibano yegranite unokuchaphazela ukuchaneka kwesixhobo kwaye kufuneka ulungiswe ngoko nangoko.

Ukongeza, kuyacetyiswa ukuba kwenziwe uhlolo lokulinganisa rhoqo ukuqinisekisa ukuba isixhobo sokubeka i-optical waveguide sisebenza ngaphakathi kwemida yokuchaneka echaziweyo. Uhlolo lokulinganisa rhoqo lunokuphucula ukuchaneka kwesixhobo kwaye lwandise ubomi baso.

4. Indawo yokugcina izinto

Xa ugcina isixhobo sokubeka i-optical waveguide, kubalulekile ukusigcina kwindawo efanelekileyo. Esi sixhobo kufuneka sigcinwe kwindawo eyomileyo, epholileyo, kude nayo nayiphi na imithombo yobushushu, ukufuma okanye ilanga ngqo. Oku kuya kuthintela nawuphi na umonakalo okanye ukugqwetheka okunokuchaphazela ukuchaneka kwesixhobo.

Ukuqukumbela, ukusetyenziswa ngokufanelekileyo kunye nokugcinwa kwendibano yegranite kwisixhobo sakho sokubeka i-waveguide ye-optical kubalulekile ekuqinisekiseni ukuchaneka, ukuchaneka, kunye nobude bexesha. Ngamaxesha onke, phatha indibano yegranite ngokuqinileyo, uyigcine icocekile kwaye ingenazo inkunkuma, gcina isixhobo rhoqo, kwaye usigcine kwindawo efanelekileyo. Ngokulandela la macebiso, uya kukwazi ukugcina isixhobo sakho sokubeka i-waveguide ye-optical sisebenza kakuhle, kwaye ufumane iziphumo ezichanekileyo nezithembekileyo ngalo lonke ixesha.

Ixesha lokuthumela: Disemba-04-2023