Izinto zegranite ziyinxalenye ebalulekileyo yezixhobo ze-semiconductor ezisetyenziswa kwinkqubo yokwenziwa kwee-microchips kunye neesekethe ezidibeneyo. Ezi zinto zenziwe ngamatye endalo akumgangatho ophezulu akhiwe ukuze ahlangabezane neemfuno ezithile zoshishino lwe-semiconductor. Igranite lukhetho oludumileyo kwizixhobo zokwenza i-semiconductor ngenxa yamandla ayo abalaseleyo, ukuqina, kunye nokuzinza kobushushu. Kweli nqaku, siza kuhlola imisebenzi ephambili yezinto zegranite kwizixhobo ze-semiconductor.

1. Ukudambisa ukungcangcazela

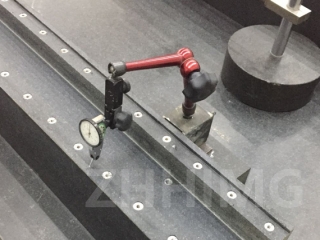

Omnye wemisebenzi ephambili yamacandelo egranite kwizixhobo ze-semiconductor kukubonelela ngokudambisa ukungcangcazela. Ukwenziwa kwe-microchip kufuna indawo ecocekileyo nezinzileyo, kwaye ukungcangcazela kunokubangela ungcoliseko kunye nokuphazamisa inkqubo yokwenziwa. Amacandelo egranite asetyenziswa kwiindawo ezibalulekileyo zezixhobo ze-semiconductor, ezifana nee-wafer chucks kunye nezigaba, ukufunxa kunye nokuthomalalisa ukungcangcazela okubangelwa kukuhamba kwezixhobo okanye izinto zangaphandle.

2. Uzinzo lobushushu

Izixhobo zegranite zaziwa ngokuzinza kwazo okugqwesileyo kobushushu. Inkqubo yokuvelisa i-semiconductor ifuna amaqondo obushushu aphezulu, kwaye izixhobo kufuneka zigcine amaqondo obushushu azinzileyo ukuze kuthintelwe iimpazamo okanye ukungasebenzi kakuhle. Izixhobo zegranite zine-coefficient ephantsi yokwandiswa kobushushu, oko kuthetha ukuba azivali okanye zinciphe kakhulu xa kukho utshintsho kumaqondo obushushu. Olu phawu lwenza izixhobo zikwazi ukugcina amaqondo obushushu azinzileyo kwaye zinciphise i-gradients yamaqondo obushushu.

3. Uzinzo olunemilinganiselo

Omnye umsebenzi obalulekileyo wezixhobo zegranite kukuzinza okulinganayo ezikunikayo. Inkqubo yokuvelisa ifuna ukuchaneka nokuchaneka, kwaye izixhobo kufuneka zigcine ubungakanani bazo obuchanekileyo kuyo yonke inkqubo. Izixhobo zegranite zinobulukhuni obuphezulu kunye nokwanda okuphantsi kobushushu, oko kuthetha ukuba azinangxaki yokuguquguquka okubangelwa kukutshintsha kobushushu okanye amandla angaphandle. Olu phawu luqinisekisa ukuba izixhobo zigcina ubukhulu bazo obuchanekileyo ngexesha lenkqubo yokuvelisa.

4. Ukumelana neekhemikhali

Izinto zegranite azinazo iikhemikhali kwaye ziyamelana neekhemikhali ezininzi ezisetyenziswa kakhulu kwishishini le-semiconductor. Ukumelana neekhemikhali kubalulekile kuba inkqubo yokuvelisa ibandakanya ukusetyenziswa kweekhemikhali ezahlukeneyo ezifana nee-asidi, iziseko, kunye nezinyibilikisi ezinokonakalisa izixhobo. Izinto zegranite zinokumelana nokuchatshazelwa zezi khemikhali, zinciphise umngcipheko wokonakala kwezixhobo kwaye ziqinisekise ukuba inkqubo yokuvelisa isebenza kakuhle.

5. Ucoceko

Izinto zegranite kulula ukuzicoca nokuzigcina zisemgangathweni. Zinomphezulu ogudileyo owenza kube lula ukuzisula kwaye azinazo iintsholongwane okanye ezinye izinto ezingcolisayo, nto leyo eyenza ukuba zilungele ukusetyenziswa kwiindawo ezicocekileyo. Ucoceko lubalulekile kwinkqubo yokwenziwa kwe-semiconductor ukuthintela ungcoliseko lwee-microchips nokuqinisekisa umgangatho ohambelanayo.

Isiphelo

Izixhobo zegranite zidlala indima ebalulekileyo kwizixhobo ze-semiconductor kwaye zinegalelo ekuchanekeni nasekuchanekeni okufunekayo kwinkqubo yokuvelisa. Ezi zixhobo zibonelela ngokunciphisa ukungcangcazela, uzinzo lobushushu nobukhulu, ukumelana neekhemikhali, kunye nococeko, ezibalulekileyo ekusebenzeni kakuhle nangokufanelekileyo kwezixhobo. Njengoko ubuchwepheshe buqhubeka, imfuno yezixhobo ze-semiconductor ezikumgangatho ophezulu iya kuqhubeka isanda, kwaye izixhobo zegranite ziya kuhlala ziyinxalenye ebalulekileyo yesi sixhobo.

Ixesha lokuthumela: Epreli-08-2024