Kwihlabathi lokwenziwa kwezinto ezichanekileyo kakhulu, ukusebenza kwezinto zegranite mechanical kunxulumene ngokusondeleyo neempawu zazo zomphezulu—ingakumbi uburhabaxa kunye nokukhazimla. Ezi parameter zimbini zingaphezulu nje kweenkcukacha zobuhle; zichaphazela ngokuthe ngqo ukuchaneka, uzinzo, kunye nokuthembeka kwezixhobo ezichanekileyo. Ukuqonda oko kumisela uburhabaxa kunye nokukhazimla kwezinto zegranite kunceda iinjineli kunye neengcali ukuqinisekisa ukuba inxalenye nganye ihlangabezana nemigangatho efunekayo kwizicelo ezichanekileyo.

I-Granite yinto yendalo eyenziwe ikakhulu yi-quartz, i-feldspar, kunye ne-mica, ezithi xa zidibene zenze isakhiwo esiqinileyo nesinobunono, esifanelekileyo kwiindlela zokusetyenziswa koomatshini kunye ne-metrological. Uburhabaxa bomphezulu wezixhobo zoomatshini ze-granite buhlala buphakathi kwe-Ra 0.4 μm ukuya kwi-Ra 1.6 μm, kuxhomekeke kudidi, indlela yokupholisha, kunye nokusetyenziswa okucetywayo. Umzekelo, imiphezulu yokulinganisa iipleyiti ze-granite okanye iziseko zifuna amaxabiso aphantsi kakhulu oburhabaxa ukuqinisekisa ukunxibelelana ngokuchanekileyo nezixhobo kunye nezinto zokusebenza. Ixabiso eliphantsi le-Ra lithetha umphezulu othambileyo, ukunciphisa ukungqubana kunye nokuthintela iimpazamo zokulinganisa ezibangelwa kukungalungi komphezulu.

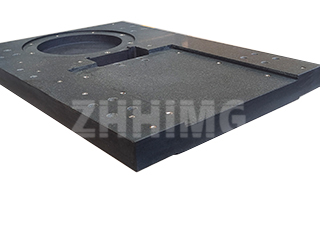

Kwi-ZHHIMG, icandelo ngalinye legranite licutshungulwa ngononophelo kusetyenziswa iindlela zokuleqa ezichanekileyo. Umphezulu ulinganiswa ngokuphindaphindiweyo kwaye ucocwe de ufikelele kwi-microflatness oyifunayo kunye nobume obufanayo. Ngokungafaniyo nemiphezulu yesinyithi, enokufuna ukugqunywa okanye unyango ukuze igcine ithambile, igranite ifikelela kwi-granite yayo ethambileyo ngokwendalo ngokupholisha okulawulwayo koomatshini. Oku kuqinisekisa umphezulu ohlala ixesha elide ogcina ukuchaneka nokuba emva kokusetyenziswa ixesha elide.

Kwelinye icala, ukukhazimla kubhekisa kumgangatho obonakalayo nobonakalayo womphezulu wegranite. Kwizinto ezichanekileyo, ukukhazimla okugqithisileyo akunqweneleki, njengoko kunokubangela ukukhanya okubonakalayo okuphazamisana nokulinganisa okubonakalayo okanye kwe-elektroniki. Ke ngoko, iindawo zegranite zihlala zigqitywa ngokubonakala okungathi matte — okugudileyo xa uchukumisa kodwa ngaphandle kokukhanya okufana nesipili. Eli nqanaba lokukhazimla elilinganiselayo liphucula ukufundeka ngexesha lokulinganisa kwaye liqinisekisa uzinzo lokukhanya kwizixhobo ezichanekileyo ezifana noomatshini bokulinganisa abadibeneyo (ii-CMM) kunye nezigaba zokukhanya.

Izinto ezininzi zichaphazela uburhabaxa kunye nokukhazimla, kubandakanya ukwakheka kweeminerali zegranite, ubungakanani beenkozo, kunye nendlela yokupolisha. Igranite emnyama ekumgangatho ophezulu, efana ne-ZHHIMG® Black Granite, ineeminerali ezintle, ezisasazwe ngokulinganayo ezivumela ukugqitywa okuphezulu komphezulu ngokukhazimla okuzinzileyo kunye nokungaguquguquki komphezulu okuncinci. Olu hlobo lwegranite lukwabonelela ngokumelana nokuguguleka okugqwesileyo kunye nokuzinza okulinganayo, okubalulekileyo ekugcineni ukuchaneka kwexesha elide.

Ukuze kugcinwe imeko yomphezulu wezinto zegranite, ukugcinwa okufanelekileyo kubalulekile. Ukucoca rhoqo ngelaphu elithambileyo, elingenayo i-lint kunye nesicoci esingaboliyo kunceda ukususa uthuli kunye neentsalela zeoyile ezinokuchaphazela uburhabaxa kunye nenkangeleko ekhazimlayo. Iindawo ezikumphezulu akufuneki zikhuhlwe ngezixhobo zesinyithi okanye izinto ezirhabaxa, njengoko ezi zinokungenisa imikrwelo emincinci etshintsha ubume bomphezulu kunye nokuchaneka kokulinganisa. Ngononophelo oluchanekileyo, izinto ezikumphezulu wegranite zinokugcina iimpawu zazo zomphezulu ezichanekileyo kangangeminyaka emininzi.

Ukuqukumbela, uburhabaxa kunye nokukhazimla kwezixhobo zoomatshini begranite kubalulekile ekusebenzeni kwazo kubunjineli obuchanekileyo. Ngeenkqubo zokuvelisa eziphambili, i-ZHHIMG iqinisekisa ukuba yonke into yegranite ihlangabezana nemigangatho yamazwe ngamazwe yomgangatho womphezulu, uzinzo, kunye nokuphila ixesha elide. Ngokudibanisa iipropati zomzimba ezikhethekileyo zegranite yendalo kunye netekhnoloji yanamhlanje, i-ZHHIMG iyaqhubeka nokuxhasa amashishini apho ukuchaneka kunye nokuthembeka kuchazwa khona impumelelo.

Ixesha leposi: Okthobha-28-2025