Kwicandelo lokwenziwa kwee-semiconductor, ukucoceka kwendawo yokucoca kuchaphazela ngokuthe ngqo izinga lemveliso yee-wafer kunye nokusebenza kwee-chips. Izityalo ezi-5 eziphezulu zokwenza ii-wafer emhlabeni zonke ziye zasusa izixhobo zesinyithi zendabuko zaza zatshintshela kumaqonga e-granite. Emva kolu tshintsho kukho ukufuna indawo engenangcoliseko kumagumbi okucoca. Amaqonga e-granite, aneempawu zawo, abonakalise iingenelo ezingenakuthelekiswa nanto kumagumbi acocekileyo kwaye abe yeyona nto intsha ithandwayo kwizityalo zokwenza ii-wafer.

"Isiphene esibulalayo" sezinto zesinyithi ezifakwe kumagumbi acocekileyo

Isinyithi esixonxiweyo, njengesixhobo semveli soshishino, sakha saba neengenelo ezithile kwiimpawu zoomatshini, kodwa sineengxaki ezininzi kwindawo yokucoca ye-semiconductor. Okokuqala, ulwakhiwo oluphezulu lwesinyithi esixonxiweyo aluxinene, lunenani elikhulu leembobo kunye nemingxunya emincinci engabonakaliyo emehlweni. Ngexesha lokusebenza kwemihla ngemihla kweendawo zokucoca, ezi mbobo zinomdla kakhulu wokufunxa uthuli, amabala eoyile kunye nokungcola okwahlukeneyo kweekhemikhali, zibe ziindawo zokufihla imithombo yongcoliseko. Nje ukuba izinto ezingcolisayo ziqokelelene, ngexesha lokusebenza ngokuchanekileyo kokwenziwa kwe-wafer, zinokuwa zinamathele kumphezulu we-wafer, zibangele iingxaki ezinkulu zomgangatho ezifana neesekethe ezimfutshane kunye neesekethe ezivulekileyo kwi-chip.

Okwesibini, isinyithi esityhidiweyo asinazinzo kangako kwiikhemikhali. Ngexesha lenkqubo yokwenziwa kwe-wafer, kusetyenziswa ii-reagents ezahlukeneyo zeekhemikhali ezityhidiweyo ezifana ne-hydrofluoric acid kunye ne-sulfuric acid. Isinyithi esityhidiweyo sithambekele ekugugulekeni nasekugugulekeni phantsi kokukhukuliseka kwezi zinto zeekhemikhali. Umhlwa kunye nee-ion zesinyithi eziveliswa kukugqwala azingcolisi nje kuphela indawo yokucoca kodwa zinokuphinda zisebenzise ii-chemical reactions kwizinto ezikumphezulu we-wafer, zonakalisa iipropati zomzimba nezekhemikhali zee-wafers kwaye zinciphise kakhulu isivuno semveliso.

Uphawu "lokungangcoliseki" kwamaqonga egranite

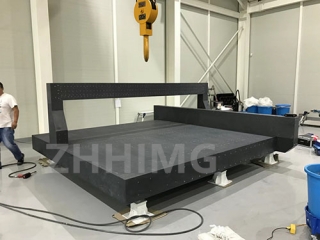

Isizathu sokuba amaqonga egranite athandwe zizityalo zokwenza iiwafer eziphezulu ezi-5 kwihlabathi liphela sisizathu sazo "sokungangcoliseki". Igranite lilitye lendalo elenziwe ngeenkqubo zejoloji kwiminyaka engamakhulu ezigidi. Iikristale zayo zangaphakathi zeminerali ziqiniswe kakhulu, isakhiwo sixinene kwaye siyafana, kwaye phantse akukho mingxunya kumphezulu. Olu lwakhiwo lukhethekileyo luqinisekisa ukuba aluyi kufunxa uthuli kunye nezinto ezingcolisayo. Nokuba kukho ukuphazamiseka komoya rhoqo kunye nemisebenzi yabasebenzi kunye nezixhobo kwigumbi elicocekileyo, umphezulu weqonga legranite usenokuhlala ucocekile, uthintela ukuzala kunye nokusasazeka kwezinto ezingcolisayo.

Ngokuphathelele ukuzinza kweekhemikhali, igranite isebenza kakuhle kakhulu. Izinto zayo eziphambili ziiminerali ezifana ne-quartz kunye ne-feldspar. Ineempawu zeekhemikhali ezizinzileyo kakhulu kwaye ayisebenzi kangako kwii-reagents zeekhemikhali eziqhelekileyo. Kwimeko-bume entsonkothileyo yeekhemikhali yokwenziwa kwe-wafer, amaqonga egranite anokusingatha ukukhukuliseka kwee-reagents ezahlukeneyo ezibolayo ngokulula, ngaphandle kokuvelisa iimveliso zokubola okanye ungcoliseko lwee-ion zesinyithi, nto leyo ebonelela ngeqonga elisisiseko elikhuselekileyo nelicocekileyo lokuvelisa i-wafer. Okwangoku, igranite ayisebenzisi umbane kwaye ayivelisi umbane ongashukumiyo, ngaloo ndlela ithintela umngcipheko wongcoliseko olubangelwa ngumbane ongashukumiyo ofunxa amasuntswana othuli kwaye iqinisekisa ngakumbi umgangatho wokusingqongileyo wegumbi elicocekileyo.

Ukukhethwa kwezinto ngokwembono yeendleko kunye nenzuzo

Nangona iindleko zokuqala zokuthenga iiplatifomu zegranite ziphezulu kakhulu kunezo zesinyithi esityhidiweyo, ekuhambeni kwexesha, iingenelo ezipheleleyo ezizisayo zidlula kakhulu umahluko weendleko. Ukucocwa rhoqo kunye nokugcinwa kweeplatifomu zesinyithi esityhidiweyo ngenxa yeengxaki zongcoliseko, kunye nelahleko enkulu ebangelwa kukwanda kwamazinga eziphene zemveliso, kugcine iindleko zemveliso ziphezulu. Iplatifomu yegranite, enenzuzo yayo yongcoliseko, inciphisa kakhulu ukuphindaphindeka kokucoca kunye nokugcinwa kwigumbi elicocekileyo kunye nezinga leziphene zeemveliso, yehlisa iindleko zokusebenza, kwaye iphucula ukusebenza kakuhle kwemveliso kunye nomgangatho wemveliso. Cinga ngomzi-mveliso onomthamo wonyaka wemveliso we-wafers ezizigidi ezi-1 njengomzekelo. Emva kokwamkela iiplatifomu zegranite, inokunciphisa ilahleko ezibangelwa lungcoliseko ngaphezulu kwe-yuan ezizigidi ezilishumi ngonyaka, kwaye imbuyekezo kutyalo-mali ibaluleke kakhulu.

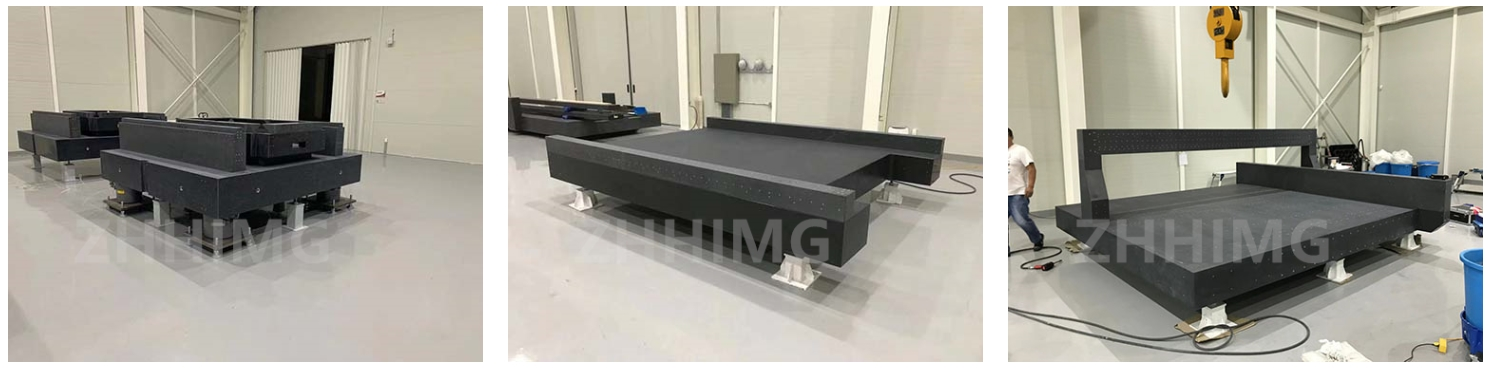

Izityalo ezi-TOP 5 zehlabathi ezenza ii-wafer ziye zashiya i-cast iron kunye neeplatifomu ze-granite ezikhethiweyo ngokusekelwe ekuqwalaselweni okubanzi kweemfuno zeendawo zokucoca kunye nokusebenza kakuhle kwemveliso. Inzuzo yokungcoliswa kwamaplatifomu e-granite inika isiqinisekiso esithembekileyo semveliso ye-wafer kwaye iqhubela phambili ukwenziwa kwee-semiconductor ukuya ngokuchanekileyo okuphezulu kunye namazinga aphezulu esivuno. Ngophuhliso oluqhubekayo lwetekhnoloji ye-semiconductor, amaplatifomu e-granite aya kudlala indima ebaluleke ngakumbi kwimveliso ye-wafer yexesha elizayo.

Ixesha leposi: Meyi-14-2025