I-Granite luhlobo lwelitye elitshisiweyo elimbiwa ngenxa yamandla alo agqithisileyo, ubuninzi, ukuqina, kunye nokumelana nokugqwala. Kodwa i-granite ikwanokuguquguquka kakhulu- ayisiyoyezikwere kunye neengxande kuphela! Enyanisweni, sisebenza ngokuzithemba ngezinto ze-granite ezenziwe ngeemilo, ii-engile, kunye nee-curves zazo zonke iintlobo rhoqo-ngeziphumo ezigqwesileyo.

Ngenxa yokulungiswa kwethu okusemgangathweni, iindawo ezisikiweyo zingaba tyaba kakhulu. Ezi mpawu zenza i-granite ibe yeyona nto ifanelekileyo yokwenza iziseko zoomatshini kunye nezixhobo ze-metrology ezinobukhulu obuqhelekileyo kunye noyilo oluqhelekileyo. I-Granite yile:

■ enokusetyenzwa ngomatshini

■ tyaba ngokuchanekileyo xa isikiwe kwaye igqityiwe

■ ukumelana nomhlwa

■ eqinileyo

■ ihlala ixesha elide

Izinto zegranite nazo kulula ukuzicoca. Xa usenza uyilo olukhethekileyo, qiniseka ukuba ukhetha igranite ngenxa yezibonelelo zayo ezibalaseleyo.

IIMFANELO / IZICELO ZOKUNXIBA OKUPHEZULU

I-granite esetyenziswa yi-ZHHIMG kwiimveliso zethu zeplati zomphezulu ezisemgangathweni inomxholo ophezulu we-quartz, nto leyo enika ukumelana okukhulu nokuguguleka kunye nokonakala. Imibala yethu emnyama ephezulu inezinga eliphantsi lokufunxwa kwamanzi, nto leyo enciphisa amathuba okuba ii-precision gauges zakho zigrule ngelixa zibekwe kwiiplati. Imibala yegranite enikezelwa yi-ZHHIMG ibangela ukukhanya okuncinci, nto leyo ethetha ukuba amehlo angaphantsi kubantu abasebenzisa iiplati. Sikhethe iintlobo zethu zegranite ngelixa sicinga ngokwandiswa kobushushu ukuze sigcine olu phawu luncinci.

ISICELO ESISEKELWEYO

Xa usetyenziso lwakho lufuna ipleyiti enemilo eyenzelwe wena, izinto ezifakwe imisonto, iindawo zokufaka okanye ezinye izinto zokulungisa, kuya kufuneka ukhethe izinto ezifana neBlack Jinan Black. Ezi zinto zendalo zinika ukuqina okuphezulu, ukudambisa ukungcangcazela okugqwesileyo, kunye nokuphucula ukusebenza koomatshini.

Kubalulekile ukuqaphela ukuba umbala wodwa awubonisi iimpawu zomzimba zelitye. Ngokubanzi, umbala wegranite unxulumene ngokuthe ngqo nokuba khona okanye ukungabikho kweeminerali, ezinokuthi zingabi nafuthe kwiimpawu ezenza izinto ezilungileyo zepleyiti yomphezulu. Kukho iigranite ezipinki, ezingwevu, nezimnyama ezilungele iipleyiti zomphezulu, kunye neegranite ezimnyama, ezingwevu, nezipinki ezingafanelekiyo kwaphela ekusetyenzisweni ngokuchanekileyo. Iimpawu ezibalulekileyo zegranite, njengoko ziphathelele ukusetyenziswa kwayo njengezinto zepleyiti yomphezulu, azinanto yakwenza nombala, kwaye zezi zilandelayo:

■ Ukuqina (ukuphambuka phantsi komthwalo - kuboniswe yiModulus of Elasticity)

■ Ukuqina

■ Uxinano

■ Ukumelana nokunxitywa

■ Uzinzo

■ Ukufunxa

Sivavanye izinto ezininzi zegranite saza sazithelekisa ezi zinto. Ekugqibeleni sifumana isiphumo, igranite emnyama yaseJinan yeyona nto ibalaseleyo esakha sayazi. Igranite emnyama yaseIndiya kunye negranite yaseMzantsi Afrika zifana neGranite emnyama yaseJinan, kodwa iimpawu zazo zomzimba zincinci kuneGranite emnyama yaseJinan. I-ZHHIMG iya kuqhubeka ikhangela ezinye izinto zegranite ehlabathini kwaye ithelekise iimpawu zazo zomzimba.

Ukuze uthethe ngakumbi ngegranite efanelekileyo kwiprojekthi yakho, nceda unxibelelane nathiinfo@zhhimg.com.

Abavelisi abahlukeneyo basebenzisa imigangatho eyahlukeneyo. Kukho imigangatho emininzi ehlabathini.

I-DIN Standard, i-ASME B89.3.7-2013 okanye i-Federal Specification GGG-P-463c (ii-Granite Surface Plates) njalo njalo njengesiseko seenkcukacha zazo.

Kwaye singavelisa ipleyiti yokuhlola ngokuchanekileyo kwegranite ngokweemfuno zakho. Wamkelekile ukuba unxibelelane nathi ukuba ufuna ukwazi ulwazi oluthe kratya malunga nemigangatho engaphezulu.

Ukuthe tyaba kungathathwa njengokuba onke amanqaku aphezu komhlaba equlethwe kwiiplani ezimbini ezihambelanayo, iplani esisiseko kunye neplani yophahla. Ukulinganiswa komgama phakathi kweplani kukuthe tyaba ngokubanzi komphezulu. Olu linganiso lokuthe tyaba ludla ngokuba nokunyamezelana kwaye lunokubandakanya uphawu lwebanga.

Umzekelo, ukunyamezelana kwe-flatness kwamabakala amathathu asemgangathweni kuchazwa kwinkcazo karhulumente njengoko kumiselwe yile fomyula ilandelayo:

■ Ibanga leLebhu i-AA = (40 + i-diagonal square/25) x .000001" (ecaleni elinye)

■ Uvavanyo lweBanga A = Ilebhu yeBanga AA x 2

■ Igumbi leZixhobo Ibanga B = Ibanga leLebhu AA x 4.

Kwiipleyiti zomphezulu ezinobukhulu obuqhelekileyo, siqinisekisa ukunyamezelana kokuthe tyaba okugqitha iimfuno zale nkcazo. Ukongeza kokuthe tyaba, i-ASME B89.3.7-2013 kunye ne-Federal Specification GGG-P-463c zijongana nezihloko eziquka: ukuchaneka kokulinganisa okuphindaphindiweyo, iimpawu zezinto zegranite zepleyiti yomphezulu, ukugqitywa komphezulu, indawo yenkxaso, ukuqina, iindlela ezamkelekileyo zokuhlola, ukufakwa kwezinto ezifakwe ngemisonto, njl.njl.

Iipleyiti zomphezulu wegranite ze-ZHHIMG kunye neepleyiti zokuhlola igranite ziyahlangabezana okanye zidlule zonke iimfuno ezichazwe kule nkcazo. Okwangoku, akukho nkcazo icacileyo yeepleyiti ze-angle zegranite, ii-parallels, okanye ii-master squares.

Kwaye ungazifumana iifomyula zeminye imigangatho kuKHUPHELA.

Okokuqala, kubalulekile ukugcina ipleyiti icocekile. Uthuli olurhabaxa oluqhutywa ngumoya ludla ngokuba lolona mthombo mkhulu wokukrazuka kwepleyiti, njengoko ludla ngokungena kwiindawo zokusebenza kunye neendawo ezidibanayo zeegeyiji. Okwesibini, gquma ipleyiti yakho ukuze uyikhusele eluthulini nasekonakaleni. Ubomi bokunxiba bunokwandiswa ngokugubungela ipleyiti xa ingasetyenziswa, ngokuyijikelezisa rhoqo ukuze indawo enye ingafumani ukusetyenziswa okugqithisileyo, nangokutshintsha iiphedi zoqhagamshelwano zentsimbi xa zilinganiswa ngeephedi ze-carbide. Kwakhona, kuphephe ukubeka ukutya okanye iziselo ezibandayo kwipleyiti. Qaphela ukuba iziselo ezininzi ezibandayo ziqulethe i-carbonic okanye i-phosphoric acid, enokunyibilikisa iiminerali ezithambileyo kwaye ishiye imingxunya emincinci kumphezulu.

Oku kuxhomekeke kwindlela esetyenziswa ngayo ipleyiti. Ukuba kunokwenzeka, sicebisa ukuba ucoce ipleyiti ekuqaleni kosuku (okanye ishifti yomsebenzi) uze uyicoce kwakhona ekupheleni kwayo. Ukuba ipleyiti ingcola, ingakumbi ngolwelo olunamafutha okanye olunamathelayo, kufuneka icocwe ngoko nangoko.

Coca ipleyiti rhoqo ngesicoci sepleyiti esingenamanzi okanye i-ZHHIMG Waterless surface plate. Ukukhetha izisombululo zokucoca kubalulekile. Ukuba kusetyenziswa isinyibilikisi esiguquguqukayo (i-acetone, i-lacquer thinner, i-alcohol, njl.njl.) ukufuma kuya kupholisa umphezulu, kwaye kuwuphazamise. Kwimeko enjalo, kuyimfuneko ukuvumela ipleyiti ukuba iqheleke ngaphambi kokuba uyisebenzise okanye kuya kwenzeka iimpazamo zokulinganisa.

Ixesha elifunekayo ukuze ipleyiti ihlale ikwimeko entle liya kwahluka ngokobukhulu bepleyiti, kunye nobungakanani bokuphola. Iyure enye mayibe yanele iipleyiti ezincinci. Kunokufuneka iiyure ezimbini kwiipleyiti ezinkulu. Ukuba kusetyenziswa isicoci esisekelwe emanzini, kuya kubakho nokuphola okubangelwa kukufuma.

Ipleyiti iya kugcina amanzi, kwaye oku kunokubangela ukugqwala kweendawo zesinyithi xa zidibene nomphezulu. Ezinye izixhobo zokucoca ziya kushiya intsalela enamathelayo emva kokuba zomile, nto leyo eya kutsala uthuli oluphuma emoyeni, kwaye ngokwenene yonyuse ukuguguleka, endaweni yokunciphisa.

Oku kuxhomekeke ekusetyenzisweni kwepleyiti kunye nendawo engqongileyo. Sicebisa ukuba ipleyiti entsha okanye isixhobo segranite esichanekileyo sifumane uhlengahlengiso olupheleleyo kungekapheli unyaka omnye wokuthengwa. Ukuba ipleyiti yomphezulu wegranite iya kusetyenziswa kakhulu, kungacetyiswa ukuba sinciphise eli xesha liye kwiinyanga ezintandathu. Ukuhlolwa kwenyanga nganye kweempazamo zokulinganisa eziphindaphindwayo kusetyenziswa inqanaba le-elektroniki, okanye isixhobo esifanayo kuya kubonisa naziphi na iindawo zokuguguleka ezikhulayo kwaye kuthatha imizuzu embalwa kuphela ukusebenza. Emva kokuba iziphumo zohlengahlengiso lokuqala zichongiwe, ixesha lohlengahlengiso linokwandiswa okanye lifinyezwe njengoko kuvunyelwe okanye kufunwa yinkqubo yakho yomgangatho wangaphakathi.

Singakunika inkonzo yokukunceda uhlole kwaye ulinganise ipleyiti yakho yomphezulu wegranite.

Kukho izizathu ezininzi ezinokubangela umahluko phakathi kokulinganiswa:

- Umphezulu uhlanjwe ngesicombululo esishushu okanye esibandayo ngaphambi kokulungiswa, kwaye awuzange unikwe ixesha elaneleyo lokulungisa imeko.

- Ipleyiti ayixhaswanga kakuhle

- Utshintsho lobushushu

- Iidrafti

- Ukukhanya kwelanga ngqo okanye olunye ubushushu obukhanyayo kumphezulu wepleyiti. Qiniseka ukuba izibane eziphezulu azifudumezi umphezulu

- Utshintsho kwi-gradient yobushushu obuthe nkqo phakathi kobusika nehlobo (Ukuba kunokwenzeka, yazi i-vertical gradient temperature ngexesha lokwenziwa kwe-calibration.)

- Ipleyiti ayinikwanga ixesha elaneleyo lokulungisa imeko emva kokuthunyelwa

- Ukusetyenziswa gwenxa kwezixhobo zokuhlola okanye ukusetyenziswa kwezixhobo ezingalinganiswanga

- Utshintsho lomphezulu olubangelwa kukuguguleka

Kwiifektri ezininzi, amagumbi okuhlola kunye neelebhu, iipleyiti zomphezulu wegranite ezichanekileyo zixhomekeke kuzo njengesiseko sokulinganisa ngokuchanekileyo. Ngenxa yokuba umlinganiselo ngamnye othe tye uxhomekeke kumphezulu ochanekileyo wereferensi apho kuthathwa khona imilinganiselo yokugqibela, iipleyiti zomphezulu zibonelela ngeyona ndawo ifanelekileyo yokujonga umsebenzi kunye noyilo ngaphambi kokwenziwa kwemishini. Zikwasisiseko esifanelekileyo sokwenza imilinganiselo yobude kunye nokulinganisa umphezulu. Ngaphezu koko, inqanaba eliphezulu lokuthe tyaba, ukuzinza, umgangatho ngokubanzi kunye nomsebenzi osebenzayo kuzenza zibe lukhetho olufanelekileyo lokufaka iinkqubo zokulinganisa ezintsonkothileyo zoomatshini, ze-elektroniki kunye nezokukhanya. Kuzo naziphi na ezi nkqubo zokulinganisa, kubalulekile ukugcina iipleyiti zomphezulu zilinganisiwe.

Phinda imilinganiselo kunye ne-Flatness

Zombini izilinganiso zokuthe tyaba kunye neziphindaphindwayo zibalulekile ukuqinisekisa umphezulu ochanekileyo. Ukuthe tyaba kungathathwa njengeendawo zonke ezikumphezulu eziqulethwe kwiiplani ezimbini ezihambelanayo, iplani esisiseko kunye neplani yophahla. Ukulinganiswa komgama phakathi kweplani kukuthe tyaba ngokubanzi komphezulu. Olu vavanyo lokuthe tyaba ludla ngokuba nokunyamezela kwaye lunokubandakanya uphawu lwebanga.

Ukunyamezelana kwe-flatness kwamabakala amathathu asemgangathweni kuchazwa kwinkcazo karhulumente njengoko kumiselwe yile fomyula ilandelayo:

Umgangatho we-DIN, Umgangatho we-GB, Umgangatho we-ASME, Umgangatho we-JJS... ilizwe elahlukileyo elinesimo esahlukileyo...

Iinkcukacha ezithe vetshe malunga nomgangatho.

Ukongeza ekuthe tyaba, ukuphinda-phinda kufuneka kuqinisekiswe. Ukulinganisa okuphindaphindiweyo kukulinganisa iindawo ezithe tyaba zasekuhlaleni. Lumlinganiselo othathwa naphi na kumphezulu wepleyiti oya kuphinda-phinda ngaphakathi kokunyamezelana okuchaziweyo. Ukulawula ukuthe tyaba kwendawo yasekuhlaleni ukuya ekunyamezeleni okuqinileyo kunokugqithisa ngokubanzi kuqinisekisa utshintsho oluncinci kwiprofayili yokuthe tyaba yomphezulu, ngaloo ndlela kunciphisa iimpazamo zasekuhlaleni.

Ukuqinisekisa ukuba ipleyiti yomphezulu ihlangabezana neemfuno ezithe tyaba kunye nemilinganiselo ephindaphindwayo, abavelisi beepleyiti zomphezulu wegranite kufuneka basebenzise i-Federal Specification GGG-P-463c njengesiseko seenkcazo zabo. Lo mgangatho ujongana nokuchaneka kokulinganisa okuphindaphindwayo, iipropati zezinto zegranite yomphezulu wepleyiti, ukugqitywa komphezulu, indawo yenkxaso, ukuqina, iindlela ezamkelekileyo zokuhlola kunye nokufakela izinto ezifakwe ngemisonto.

Ukujonga Ukuchaneka Kwepleyiti

Ngokulandela izikhokelo ezimbalwa ezilula, utyalo-mali kwipleyiti yomphezulu wegranite lufanele luhlale iminyaka emininzi. Ngokuxhomekeke ekusetyenzisweni kwepleyiti, indawo yevenkile kunye nokuchaneka okufunekayo, amaxesha okujonga ukuchaneka kwepleyiti yomphezulu ayahluka. Umgaqo oqhelekileyo kukuba ipleyiti entsha ifumane uhlengahlengiso olupheleleyo kungekapheli unyaka omnye emva kokuthengwa. Ukuba ipleyiti isetyenziswa rhoqo, kuyacetyiswa ukuba ifinyezwe eli xesha liye kwiinyanga ezintandathu.

Ngaphambi kokuba ipleyiti yomphezulu iguge ngaphaya kwemilinganiselo yokuba ithambile iyonke, iya kubonisa izithuba ezigugileyo okanye ezigobileyo. Ukuhlolwa kwenyanga nganye kweempazamo zokulinganisa eziphindaphindwayo kusetyenziswa i-repeat reading gage kuya kuchonga amabala okuguga. I-repeat reading gage sisixhobo esichanekileyo esibona iimpazamo zasekuhlaleni kwaye sinokuboniswa kwi-high magnification electronic amplifier.

Inkqubo yokuhlola esebenzayo kufuneka iquke ukujonga rhoqo nge-autocollimator, ebonelela ngokulinganisa ngokwenene ubunzulu be-flatness obunokulandelelwa yiNational Institute of Standards and Technology (NIST). Ukulinganisa okupheleleyo ngumvelisi okanye inkampani ezimeleyo kuyimfuneko ngamanye amaxesha.

Utshintsho Phakathi koLungiso

Kwezinye iimeko, kukho umahluko phakathi kokulinganiswa kwepleyiti yomphezulu. Ngamanye amaxesha izinto ezifana nokutshintsha komphezulu okubangelwa kukuguguleka, ukusetyenziswa gwenxa kwezixhobo zokuhlola okanye ukusetyenziswa kwezixhobo ezingalinganiswanga zinokubangela olu tshintsho. Nangona kunjalo, ezona zinto zimbini zixhaphakileyo bubushushu kunye nenkxaso.

Enye yezona zinto zibalulekileyo zizinto ezitshintshayo bubushushu. Umzekelo, umphezulu usenokuba uhlanjwe ngesicombululo esishushu okanye esibandayo ngaphambi kokulungiswa kwaye awuzange unikwe ixesha elaneleyo lokulungisa. Ezinye izizathu zokutshintsha kobushushu ziquka umoya obandayo okanye oshushu, ukukhanya kwelanga ngqo, ukukhanya okuphezulu okanye eminye imithombo yobushushu obukhanyayo kumphezulu wepleyiti.

Kunokubakho notshintsho kwi-gradient yobushushu obuthe nkqo phakathi kobusika nehlobo. Kwezinye iimeko, ipleyiti ayinikwa ixesha elaneleyo lokulungisa emva kokuthunyelwa. Kungumbono olungileyo ukurekhoda ubushushu be-gradient obuthe nkqo ngexesha lokwenziwa kovavanyo.

Esinye isizathu esiqhelekileyo sokwahluka komlinganiselo wokulinganisa yipleyiti engaxhaswanga kakuhle. Ipleyiti yomphezulu kufuneka ixhaswe kwiindawo ezintathu, okungcono ukuba ibekwe kwi-20% yobude ukusuka eziphelweni zepleyiti. Izixhasi ezibini kufuneka zibekwe kwi-20% yobubanzi ukusuka kumacala amade, kwaye inkxaso eseleyo mayibekwe embindini.

Amanqaku amathathu kuphela anokuma ngokuqinileyo kuyo nayiphi na into ngaphandle komphezulu ochanekileyo. Ukuzama ukuxhasa ipleyiti kumanqaku angaphezu kwamathathu kuya kubangela ukuba ipleyiti ifumane inkxaso yayo kwiindidi ezahlukeneyo zamanqaku amathathu, ezingayi kuba ngamanqaku amathathu afanayo apho yayixhaswe khona ngexesha lokuveliswa. Oku kuya kubangela iimpazamo njengoko ipleyiti ijika ukuze ihambelane nolungiselelo olutsha lwenkxaso. Cinga ngokusebenzisa izitendi zentsimbi ezineemitha zokuxhasa ezenzelwe ukuhambelana namanqaku okuxhasa afanelekileyo. Izitendi zale njongo zihlala zifumaneka kumenzi wepleyiti yomphezulu.

Ukuba ipleyiti ixhaswe ngokufanelekileyo, ukulinganisa ngokuchanekileyo kuyimfuneko kuphela ukuba isicelo siyichazile. Ukulinganisa ngokuchanekileyo akuyimfuneko ukugcina ukuchaneka kwepleyiti exhaswe ngokufanelekileyo.

Yandisa Ubomi Bepleyiti

Ukulandela izikhokelo ezimbalwa kuya kunciphisa ukuguguleka kwepleyiti yomphezulu wegranite kwaye ekugqibeleni, kuya kwandisa ubomi bayo.

Okokuqala, kubalulekile ukugcina ipleyiti icocekile. Uthuli olurhabaxa oluqhutywa ngomoya ludla ngokuba lolona mthombo mkhulu wokuguguleka kwepleyiti, njengoko ludla ngokungena kwiindawo zokusebenza kunye neendawo ezidibanayo zeegeyiji.

Kubalulekile nokugquma iipleyiti ukuze uzikhusele eluthulini nasekonakaleni. Ixesha lokunxiba linokwandiswa ngokugquma ipleyiti xa ingasetyenziswa.

Jikelezisa ipleyiti rhoqo ukuze indawo enye ingasetyenziswa kakhulu. Kwakhona, kuyacetyiswa ukuba kutshintshwe ii-contact pads zentsimbi xa kujongwa ii-gauge ngee-carbide pads.

Kuphephe ukubeka ukutya okanye iziselo ezibandayo epleyitini. Iziselo ezininzi ezibandayo zine-carbonic okanye i-phosphoric acid, enokunyibilikisa iiminerali ezithambileyo kwaye ishiye imingxunya emincinci phezu komhlaba.

Apho Ukubuyela Umva

Xa ipleyiti yomphezulu wegranite ifuna ukuphinda ibekwe phezu kwayo, cinga ukuba le nkonzo yenziwe kwindawo okanye kwindawo yokulinganisa. Kuhlala kungcono ukuba ipleyiti ibekwe kwakhona kumzi-mveliso okanye kwindawo enikezelweyo. Nangona kunjalo, ukuba ipleyiti ayigugi kakhulu, ngokubanzi ngaphakathi kwe-intshi eziyi-0.001 yokunyamezela okufunekayo, ingaphinda ibekwe kwakhona kwindawo. Ukuba ipleyiti igugiwe ukuya kwinqanaba apho ingaphezulu kwe-intshi eziyi-0.001 ngenxa yokunyamezela, okanye ukuba igrumbe kakhulu okanye ikrumbekile, kufuneka ithunyelwe kumzi-mveliso ukuze igrumbe ngaphambi kokuba iphindwe.

Iziko lokulinganisa linezixhobo kunye nolungiselelo lwefektri olubonelela ngeemeko ezifanelekileyo zokulinganisa iipleyiti ngokufanelekileyo kunye nokuhlaziya ukuba kuyimfuneko.

Kufuneka kusetyenziswe unonophelo olukhulu ekukhetheni ingcali yokulinganisa nokulungisa umphezulu kwindawo leyo. Cela imvume kwaye uqinisekise ukuba izixhobo eziza kusetyenziswa yingcali zinokulinganiswa okulandelekayo. Amava nawo abalulekile, njengoko kuthatha iminyaka emininzi ukufunda indlela yokurhangqa ngokuchanekileyo i-granite.

Ukulinganisa okubalulekileyo kuqala ngepleyiti yomphezulu yegranite echanekileyo njengesiseko. Ngokuqinisekisa isalathiso esithembekileyo ngokusebenzisa ipleyiti yomphezulu elinganisiweyo ngokufanelekileyo, abavelisi banesinye sezixhobo ezibalulekileyo zokulinganisa okuthembekileyo kunye neenxalenye ezisemgangathweni ongcono.Q

Uluhlu lokujonga iinguqu zoLungiso

1. Umphezulu uhlanjwe ngesicombululo esishushu okanye esibandayo ngaphambi kokulungiswa kwaye awuzange unikwe ixesha elaneleyo lokulungisa imeko.

2. Ipleyiti ayixhaswanga kakuhle.

3. Utshintsho lobushushu.

4. Iidrafti.

5. Ukukhanya kwelanga ngqo okanye olunye ubushushu obukhanyayo kumphezulu wepleyiti. Qiniseka ukuba izibane ezikhanyisa ngaphezulu azifudumezi umphezulu.

6. Utshintsho kwi-gradient yobushushu obuthe nkqo phakathi kobusika nehlobo. Ukuba kunokwenzeka, yazi i-gradient yobushushu obuthe nkqo ngexesha lokulinganisa.

7. Ipleyiti ayivumelekanga ixesha elaneleyo lokulungisa emva kokuthunyelwa.

8. Ukusetyenziswa gwenxa kwezixhobo zokuhlola okanye ukusetyenziswa kwezixhobo ezingalinganiyo.

9. Utshintsho kumphezulu olubangelwa kukuguguleka.

Iingcebiso zobuchwephesha

- Ngenxa yokuba yonke imilinganiselo ethe tye ixhomekeke kumphezulu ochanekileyo wesalathiso apho kuthathwa khona imilinganiselo yokugqibela, iipleyiti zomphezulu zibonelela ngeyona ndawo ilungileyo yesalathiso sokuhlolwa komsebenzi kunye noyilo ngaphambi kokuba kwenziwe i-machining.

- Ukulawula ukuthamba kwendawo ukuya kwinqanaba eliqinileyo kunokwambatha ngokubanzi kuqinisekisa utshintsho oluncinci kwiprofayili yokuthamba komphezulu, ngaloo ndlela kunciphisa iimpazamo zendawo.

- Inkqubo yokuhlola esebenzayo kufuneka iquke ukujonga rhoqo nge-autocollimator, ebonelela ngokulinganisa ubume obuthe tyaba obunokulandelelwa yi-National Inspection Authority.

Phakathi kwee-minerali ezincinci ezenza i-granite, ngaphezulu kwe-90% yi-feldspar kunye ne-quartz, apho i-feldspar yeyona ininzi. I-feldspar idla ngokuba mhlophe, ngwevu, kwaye ibomvu njengenyama, kwaye i-quartz ikakhulu ayinambala okanye imhlophe ngwevu, nto leyo eyenza umbala osisiseko we-granite. I-Feldspar kunye ne-quartz ziiminerali eziqinileyo, kwaye kunzima ukuzihambisa ngemela yentsimbi. Ngokuphathelele amabala amnyama kwi-granite, ikakhulu i-mica emnyama, kukho ezinye iiminerali. Nangona i-biotite ithambile, amandla ayo okumelana noxinzelelo abuthathaka, kwaye kwangaxeshanye ine-granite encinci, edla ngokuba ngaphantsi kwe-10%. Le yimeko yezinto ezibonakalayo apho i-granite inamandla ngakumbi.

Esinye isizathu sokuba igranite ibe namandla kukuba amasuntswana ayo eeminerali anamathelene ngokuqinileyo kwaye anamathele omnye komnye. Iimbobo zihlala zingaphantsi kwe-1% yomthamo uwonke welitye. Oku kunika igranite amandla okumelana noxinzelelo olunamandla kwaye ayingeni lula kumswakama.

Izinto zegranite zenziwe ngamatye angenawo umhlwa, ukumelana ne-asidi kunye ne-alkali, ukumelana nokuguguleka okuhle kunye nobomi benkonzo ende, akukho londolozo lukhethekileyo. Izinto zegranite ezichanekileyo zisetyenziswa kakhulu kwizixhobo zoshishino loomatshini. Ke ngoko, zibizwa ngokuba zizinto zegranite ezichanekileyo okanye izinto zegranite. Iimpawu zezinto zegranite ezichanekileyo ziyafana nezo zamaqonga egranite. Intshayelelo ekusebenziseni izixhobo kunye nokulinganisa izinto zegranite ezichanekileyo: Umatshini wokulungisa ngokuchanekileyo kunye neteknoloji yoomatshini abancinci zizikhokelo ezibalulekileyo zophuhliso loshishino loomatshini, kwaye ziye zaba luphawu olubalulekileyo lokulinganisa inqanaba lobuchwepheshe obuphezulu. Uphuhliso lwetekhnoloji yanamhlanje kunye neshishini lokhuselo alunakwahlulwa kwiteknoloji yokulungisa ngokuchanekileyo kunye nomatshini omncinci. Izinto zegranite zinokutyibilika kakuhle kumlinganiselo, ngaphandle kokuma. Ukulinganiswa komphezulu womsebenzi, imikrwelo ngokubanzi ayichaphazeli ukuchaneka komlinganiselo. Izinto zegranite kufuneka ziyilwe kwaye ziveliswe ngokweemfuno zecala lemfuno.

Intsimi yesicelo:

Njengoko sonke sisazi, oomatshini abaninzi kunye nezixhobo zikhetha izinto zegranite ezichanekileyo.

Izixhobo zegranite zisetyenziselwa intshukumo enamandla, iimoto ezithe nkqo, i-cmm, i-cnc, umatshini we-laser...

wamkelekile ukuba unxibelelane nathi ukuze ufumane ulwazi oluthe kratya.

Izixhobo zokulinganisa igranite kunye nezixhobo zoomatshini zegranite zenziwe ngegranite emnyama ekumgangatho ophezulu. Ngenxa yokuchaneka kwazo okuphezulu, ixesha elide, uzinzo oluhle kunye nokumelana nokugqwala, ziye zasetyenziswa ngakumbi nangakumbi ekuhlolweni kwemveliso kumashishini anamhlanje nakwiindawo zesayensi ezifana nesithuba se-aero yoomatshini kunye nophando lwesayensi.

Iingenelo

----Iqine kabini kunentsimbi ephosiweyo;

----Utshintsho oluncinci lobukhulu lubangelwa lutshintsho lobushushu;

---- Ayinangxaki yokubhitya, ngoko ke akukho kuphazamiseka komsebenzi;

---- Ayinazo iibherrs okanye iiprotrusions ngenxa yesakhiwo sengqolowa esicolekileyo kunye nokunamathela okuncinci, okuqinisekisa ukuba incinci kakhulu ixesha elide kwaye ayibangeli monakalo kwezinye iindawo okanye izixhobo;

-----Ukusebenza okungenangxaki kokusetyenziswa ngezinto zemagnethi;

----Ihlala ixesha elide kwaye ayinamhlwa, nto leyo ebangela iindleko eziphantsi zokulungisa.

Iipleyiti zomphezulu wegranite ezichanekileyo zinamathele ngokuchanekileyo kumgangatho ophezulu wokuthe tyaba ukuze kufezekiswe ukuchaneka kwaye zisetyenziswa njengesiseko sokufakela iinkqubo zokulinganisa ezintsonkothileyo zoomatshini, ze-elektroniki kunye nezokukhanya.

Ezinye zeempawu ezikhethekileyo zepleyiti yomphezulu wegranite:

Ukufana kwi-Hardness;

Iimeko ezichanekileyo phantsi komthwalo;

Isifunxi sokungcangcazela;

Kulula Ukuyicoca;

Ayikwazi ukusonga;

Ukuxinana okuphantsi;

Ayirhawuzeli;

Ayinamagnethi

Iingenelo zePlate yoMphezulu weGranite

Okokuqala, ilitye emva kwexesha elide lokwaluphala kwendalo, isakhiwo esifanayo, ubuncinci be-coefficient, uxinzelelo lwangaphakathi luyanyamalala ngokupheleleyo, alunakuguqulwa, ngoko ke ukuchaneka kuphezulu.

Okwesibini, akuyi kubakho mikrwelo, kungekhona phantsi kweemeko zobushushu ezingaguqukiyo, kubushushu begumbi nako kunokugcina ukuchaneka kokulinganisa ubushushu.

Okwesithathu, hayi imagnetization, umlinganiselo unokuba yintshukumo egudileyo, akukho mvakalelo yokukrwela, ayichaphazeleki kukufuma, iplane izinzile.

Okwesine, ukuqina kwayo kulungile, ubunzima bayo buphezulu, ukumelana nokukrweleka kwayo kunamandla.

Ezintlanu, azisoyiki i-asidi, ukukhukuliseka kolwelo lwe-alkaline, aziyi kugqwala, aziyi kupeyinta ioyile, azinakuba lula ukunamathela uthuli oluncinci, zigcinwa lula, zigcinwa ixesha elide.

Kutheni ukhetha isiseko segranite endaweni yebhedi yomatshini wesinyithi?

1. Isiseko somatshini wegranite singagcina ukuchaneka okuphezulu kunesiseko somatshini wesinyithi. Isiseko somatshini wesinyithi sichaphazeleka lula bubushushu kunye nokufuma kodwa isiseko somatshini wegranite asiyi kuchaphazeleka;

2. Ngobukhulu obufanayo besiseko somatshini wegranite kunye nesiseko sesinyithi esityhidiweyo, isiseko somatshini wegranite sixabisa ngaphezulu kunesinyithi esityhidiweyo;

3. Isiseko somatshini segranite esikhethekileyo kulula ukusigqiba kunesiseko somatshini wesinyithi.

Iipleyiti zegranite surfaces zizixhobo ezibalulekileyo kwiilabhoratri zokuhlola kulo lonke ilizwe. Umphezulu olinganisiweyo, othe tyaba kakhulu wepleyiti yomphezulu uvumela abahloli ukuba bawasebenzise njengesiseko sokuhlolwa kwenxalenye kunye nokulinganiswa kwezixhobo. Ngaphandle kozinzo olunikezelwa ziipleyiti zomphezulu, uninzi lweendawo ezinyamezelweyo kakhulu kwiinkalo ezahlukeneyo zobuchwepheshe kunye nezonyango beluya kuba nzima kakhulu, ukuba akunakwenzeka, ukuzenza ngokuchanekileyo. Kakade ke, ukusebenzisa ibhloko yomphezulu wegranite ukulinganisa nokuhlola ezinye izixhobo kunye nezixhobo, ukuchaneka kwegranite ngokwayo kufuneka kuhlolwe. Abasebenzisi banokulinganisa ipleyiti yomphezulu wegranite ukuqinisekisa ukuchaneka kwayo.

Coca ipleyiti yomphezulu wegranite ngaphambi kokuba uyilinganise. Galela inani elincinci lesicoci sepleyiti yomphezulu kwilaphu elicocekileyo nelithambileyo uze usule umphezulu wegranite. Yomisa ngoko nangoko isicoci kwipleyiti yomphezulu ngelaphu elomileyo. Musa ukuvumela ulwelo lokucoca ukuba lome emoyeni.

Beka igeyiji yokulinganisa ephindaphindwayo embindini wepleyiti yomphezulu wegranite.

Faka i-zero kwi-repeat measuring gauge kumphezulu wepleyiti yegranite.

Hambisa igeyiji kancinci phezu komphezulu wegranite. Jonga isalathisi segeyiji uze ubhale phantsi iincopho zazo naziphi na iinguqulelo zobude njengoko uhambisa isixhobo phezu kwepleyiti.

Thelekisa umahluko phakathi kobuthe tyaba kumphezulu wepleyiti kunye nokumelana kwepleyiti yakho yomphezulu, eyahluka ngokusekwe kubukhulu bepleyiti kunye nomgangatho wobuthe tyaba wegranite. Jonga iinkcukacha ze-federal GGG-P-463c (jonga kwiZixhobo) ukuze ubone ukuba ipleyiti yakho iyahlangabezana na neemfuno zobukhulu bayo kunye nomgangatho wayo. Umahluko phakathi kweyona ndawo iphezulu kwipleyiti kunye neyona ndawo iphantsi kwipleyiti kukulinganiswa kwayo kobuthe tyaba.

Jonga ukuba umahluko omkhulu wobunzulu kumphezulu wepleyiti ungena kwiinkcukacha zokuphinda-phinda kwepleyiti yobukhulu nomgangatho. Jonga iinkcukacha zelizwe jikelele iGGG-P-463c (jonga iZixhobo) ukuze ubone ukuba ipleyiti yakho iyahlangabezana na neemfuno zokuphinda-phinda ngokobukhulu bayo. Yenqaba ipleyiti yomphezulu ukuba nokuba linqaku elinye liyasilela kwiimfuno zokuphinda-phinda.

Yeka ukusebenzisa ipleyiti yomphezulu wegranite engaphumeleliyo kwiimfuno zikarhulumente. Buyisela ipleyiti kumenzi okanye kwinkampani ejongene nomphezulu wegranite ukuze ibhloko ipholishwe kwakhona ukuze ihlangabezane neemfuno.

Ingcebiso

Yenza uhlengahlengiso olusemthethweni ubuncinane kanye ngonyaka, nangona iipleyiti zomphezulu wegranite ezisetyenziswa kakhulu kufuneka zilinganiswe rhoqo.

Ukulinganiswa okusemthethweni nokurekhodiweyo kwiindawo zokuvelisa okanye zokuhlola kudla ngokwenziwa ngokuqinisekiswa komgangatho okanye ngumthengisi weenkonzo zokulinganisa zangaphandle, nangona nabani na angasebenzisa igeyiji yokulinganisa ephindaphindwayo ukujonga ngokungesesikweni ipleyiti yomphezulu ngaphambi kokusetyenziswa.

Imbali Yokuqala YeePlate ZeGranite Surface

Ngaphambi kweMfazwe Yehlabathi yesiBini, abavelisi babesebenzisa iiPlati zomphezulu wentsimbi ukujonga ubukhulu beendawo. Ngexesha leMfazwe Yehlabathi yesiBini isidingo sentsimbi sanda kakhulu, kwaye iiPlati zomphezulu wentsimbi ezininzi zanyibilika. Kwakufuneka kutshintshwe, kwaye iGranite yaba yinto ekhethwayo ngenxa yeempawu zayo eziphezulu zemetrological.

Iingenelo ezininzi zegranite kunentsimbi zabonakala. Igranite inzima, nangona ibuthathaka kwaye isenokuqhekeka. Igranite ungayijika ibe tyaba kakhulu kwaye ikhawuleze kunentsimbi. Igranite ikwanophawu olufunekayo lokwandiswa kobushushu obuphantsi xa ithelekiswa nentsimbi. Ngaphezu koko, ukuba ipleyiti yentsimbi yayifuna ukulungiswa, kwakufuneka ikrwelwe ngesandla ziingcali ezisebenzisa izakhono zazo ekwakheni izixhobo zomatshini.

Njengenqaku elisecaleni, ezinye iiPlate zeSteel Surface zisasetyenziswa nanamhlanje.

Iimpawu zeMetrological zeePlate zeGranite

I-Granite lilitye eliyi-igneous elenziwe kukuqhuma kwentaba-mlilo. Xa kuthelekiswa, imabula yi-metamorphosed limestone. Ukusetyenziswa kwe-metrology, i-granite ekhethiweyo kufuneka ihlangabezane neemfuno ezithile ezichazwe kwi-Federal Specification GGG-P-463c, ukususela ngoku ebizwa ngokuba yi-Fed Specs, kwaye ngokukodwa, iCandelo 3.1 3.1 Phakathi kwe-Fed Specs, i-granite kufuneka ibe yi-texture encinci ukuya kwi-medium-grained.

I-granite yinto eqinileyo, kodwa ubulukhuni bayo buyahluka ngenxa yezizathu ezahlukeneyo. Ingcali yeplate ye-granite enamava inokuqikelela ubulukhuni bayo ngombala wayo, nto leyo ebonisa ukuba iqulathe i-quartz. Ubulukhuni be-granite buphawu oluchazwa ngokuyinxenye bubungakanani bobuncinci be-quartz kunye nokungabikho kwe-mica. Iigranite ezibomvu nezipinki zihlala zinzima, ezingwevu zinobuncinci, kwaye ezimnyama zithambile.

I-Young's Modulus of Elasticity isetyenziselwa ukubonisa ukuguquguquka okanye uphawu lobunzima belitye. I-granite epinki iphakathi kwamanqaku ama-3-5 kwisikali, i-grey ingama-5-7 amanqaku kwaye imnyama ingama-7-10 amanqaku. Okukhona inani lincinci, kokukhona i-granite ithanda ukuba nzima. Okukhona inani likhulu, kokukhona i-granite ithambile kwaye iguquguquka ngakumbi. Kubalulekile ukwazi ubunzima be-Granite xa ukhetha ubukhulu obufunekayo kwiindidi zokunyamezela kunye nobunzima beendawo kunye neegeyiji ezibekwe phezu kwayo.

Kwimihla yakudala xa kwakukho oomatshini bokwenyani, ababesaziwa ngeencwadana zabo zeetafile ezikwiipokotho zeehempe zabo, i-black granite yayithathwa njengeyona "Ingcono Kakhulu." I-Best ichazwa njengohlobo olunika ukumelana nokuguguleka okanye olunzima. Enye ingxaki kukuba ii-granite eziqinileyo zidla ngokuqhekeka okanye ukuqhekeka lula. Ooomatshini babeqinisekile ukuba i-black granite yeyona ilungileyo kangangokuba abanye abavelisi be-pink granite babeyidaya ngombala omnyama.

Ndizibonele ngokwam ipleyiti elahliwe kwi-forklift xa isuswa kwindawo yokugcina. Ipleyiti yawa phantsi yaza yahlukana phakathi yabonisa umbala opinki wokwenene. Lumka xa uceba ukuthenga i-granite emnyama eTshayina. Sicebisa ukuba uchithe imali yakho ngenye indlela. Ipleyiti yegranite inokwahluka ngobunzima bayo. Umgca we-quartz unokuba nzima kakhulu kunezinye iipleyiti zomphezulu. Umaleko we-gabbro emnyama unokwenza indawo ithambe ngakumbi. Iingcali zokulungisa iipleyiti zomphezulu eziqeqeshwe kakuhle nezinamava ziyazi indlela yokusingatha ezi ndawo zithambileyo.

Amabanga ePlate yomphezulu

Kukho amanqanaba amane eepleyiti zomphezulu. Amanqanaba e-AA kunye ne-A elebhu, iBanga loHlolo lweGumbi B, kwaye elesine yiBanga loHlolo. Amanqanaba e-AA kunye ne-A zezona zithe tyaba kakhulu kwaye zinokunyamezelana okuthe tyaba okungaphezulu kune-0.00001 kwipleyiti yeBanga le-AA. Amanqanaba eWorkshop awona athe tyaba kancinci kwaye njengoko igama lisitsho, zenzelwe ukusetyenziswa kumagumbi ezixhobo. Apho njengoko iBanga le-AA, iBanga le-A kunye neBanga le-B zenzelwe ukusetyenziswa kwilebhu yokuhlola okanye yokulawula umgangatho.

PUvavanyo lwe-roper lokulinganisa iPlate yomphezulu

Bendisoloko ndixelela abathengi bam ukuba ndingamkhupha nawuphi na umntwana oneminyaka eli-10 ecaweni yam ndize ndimfundise kwiintsuku ezimbalwa nje indlela yokuvavanya ipleyiti. Akunzima. Kufuna ubuchule obuthile ukuze kwenziwe umsebenzi ngokukhawuleza, ubuchule obufundwayo ngokuhamba kwexesha kunye nokuphindaphinda okuninzi. Ndingakuxelela, kwaye andinakugxininisa ngokwaneleyo, iFed Spec GGG-P-463c AYIYONA inkqubo yokulinganisa! Okunye malunga noko kamva.

Ukulinganisa ubume obuthe tyaba (iMean Pane) kunye nokuhlolwa kokuphinda-phinda (ukuguguleka kwendawo) kuyimfuneko Ngokwee-Fed Specs. Okukuphela kokungahambelani koku kukwiipleyiti ezincinci apho ukuphinda-phinda kufuneka kuphela.

Kwakhona, kwaye okubaluleke kakhulu njengezinye iimvavanyo, luvavanyo lwe-thermal gradients. (Jonga i-Delta T ngezantsi)

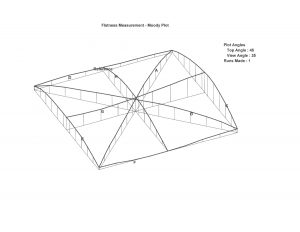

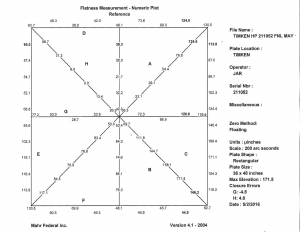

Umfanekiso 1

Uvavanyo lweFlatness luneendlela ezi-4 ezivunyiweyo. Amanqanaba e-elektroniki, i-autocollimation, i-laser kunye nesixhobo esaziwa ngokuba yi-plane locator. Sisebenzisa amanqanaba e-elektroniki kuphela kuba zezona ndlela zichanekileyo nezikhawulezayo ngezizathu ezahlukeneyo.

Iilaser kunye nee-autocollimators zisebenzisa umqadi wokukhanya othe tye kakhulu njengesalathiso. Umntu wenza umlinganiselo wobume beplate yomphezulu wegranite ngokuthelekisa umahluko kumgama phakathi kweplate yomphezulu kunye nomqadi wokukhanya. Ngokuthatha umqadi wokukhanya othe tye, uwubethele kwithagethi yokubonakalisa ngelixa uhambisa ithagethi yokubonakalisa phantsi kweplate yomphezulu, umgama phakathi komqadi okhutshwayo kunye nomqadi wokubuya ngumlinganiselo wobume beplate.

Nantsi ingxaki ngale ndlela. Ithagethi kunye nomthombo zichaphazeleka kukungcangcazela, ubushushu obungqongileyo, ithagethi engaphantsi kwethe tyaba okanye ekrwelekileyo, ungcoliseko emoyeni, kunye nokuhamba komoya (imisinga). Zonke ezi zinto zinegalelo kwizakhi ezongezelelweyo zempazamo. Ngaphezu koko, igalelo lempazamo yomqhubi evela ekuhlolweni nge-autocollimator likhulu.

Umsebenzisi onamava we-autocollimator unokwenza imilinganiselo echanekileyo kodwa usajongene neengxaki ngokuhambelana kokufundwa ngakumbi xa umgama omde njengoko ukubonakaliswa kudla ngokuba kukhulu okanye kube lufifi kancinci. Kwakhona, ithagethi engathanga tyaba ngokupheleleyo kunye nosuku olude lokujonga ngelensi kuvelisa iimpazamo ezongezelelweyo.

Isixhobo sokufumana indawo kwiplane siyinto nje engenamsebenzi. Esi sixhobo sisebenzisa ukukhanya okuthe tye (xa kuthelekiswa nokukhanya okuthe tye kakhulu okanye ukukhanya kwelaser) njengereferensi yaso. Esi sixhobo soomatshini asisebenzisi nje kuphela isalathisi esiqhelekileyo esinesisombululo se-20 u Inch kuphela kodwa ukungaguquguquki kwebha kunye nezinto ezahlukeneyo kongeza kakhulu kwiimpazamo zokulinganisa. Ngokoluvo lwethu, nangona le ndlela yamkelekile, akukho labhoratri ifanelekileyo enokusebenzisa isixhobo sokufumana indawo kwiplane njengesixhobo sokugqibela sokuhlola.

Amanqanaba e-elektroniki asebenzisa amandla angaphantsi komhlaba njengesalathiso sawo. Amanqanaba e-elektroniki ahlukeneyo awachaphazeleki kukungcangcazela. Anesisombululo esiphantsi njenge-.1 arc second kwaye imilinganiselo ikhawuleza, ichanekile kwaye akukho negalelo lincinci kakhulu lempazamo evela kumqhubi onamava. Ii-Plane Locators okanye ii-autocollimators aziboneleli nge-topographical eyenziwe yikhompyutha (Umfanekiso 1) okanye ii-isometric plots (Umfanekiso 2) womphezulu.

Umfanekiso 2

Uvavanyo oluLungileyo loMphezulu

Uvavanyo lomphezulu oluchanekileyo lubaluleke kakhulu kule phepha, bendifanele ukuba ndilubeke ekuqaleni. Njengoko bekutshiwo ngaphambili, iFed Spec. GGG-p-463c AYIYONA ndlela yokulinganisa. Isebenza njengesikhokelo kwiinkalo ezininzi zegranite ye-metrology grade apho umthengi wayo yi-Arhente kaRhulumente weSizwe, kwaye oko kuquka iindlela zokuvavanya kunye nokunyamezelana okanye amabakala. Ukuba umthengisi uthi ubambelele kwiFed Specs, ixabiso le-flatness liya kugqitywa yiMoody Method.

UMoody wayengumntu owayevela kwiminyaka yoo-1950 owayila indlela yezibalo ukuze abone ukuba ithambe kangakanani aze achaze indlela imigca evavanyiweyo ejongwa ngayo, nokuba isondelelene ngokwaneleyo na kwindawo enye. Akukho nto itshintshileyo. I-Allied Signal yazama ukuphucula indlela yezibalo kodwa yagqiba kwelokuba umahluko wawumncinci kangangokuba wawungafanelekanga.

Ukuba umntu osebenza ngepleyiti yomphezulu usebenzisa amanqanaba e-elektroniki okanye i-laser, usebenzisa ikhompyutha ukumnceda ngezibalo. Ngaphandle koncedo lwekhompyutha, ingcali esebenzisa i-autocollimation kufuneka ibale ukufundwa ngesandla. Enyanisweni, ayenzi njalo. Kuthatha ixesha elide kakhulu kwaye ngokunyanisekileyo kunokuba nzima kakhulu. Kuvavanyo lokuthamba kusetyenziswa iMoody Method, ingcali ivavanya imigca esibhozo kwisimo se-Union Jack ukuze iqonde ukuba ilungile na.

Indlela yeMoody

IMoody Method yindlela yezibalo yokufumanisa ukuba imigca esibhozo ikwindawo enye na. Ngaphandle koko, unemigca ethe tye esi-8 enokuba kwindawo enye okanye ingabi kufutshane nayo. Ngaphezu koko, umakhi othi unamathela kwiFed Spec, kwaye usebenzisa i-autocollimation, yenakufunekavelisa amaphepha asibhozo edatha. Iphepha elinye kumgca ngamnye lihlolwe ukuqinisekisa uvavanyo lwakhe, ukulungiswa, okanye zombini. Ngaphandle koko, umakhi akanalo ulwazi lokuba ixabiso lokwenyani lokutyibilika lithini.

Ndiqinisekile ukuba ungomnye wabo bavavanywa iipleyiti zakho ngumqambi osebenzisa i-autocollimation, awukaze uwabone loo maphepha! Umfanekiso 3 ngumzekelo wenje enyeiphepha lesibhozo elifunekayo ukubala ubunzulu bento yonke. Enye into ebonisa ukuba awuyazi loo nto kwaye ulunya kukuba ingxelo yakho inamanani amahle ajikeleziweyo. Umzekelo, 200, 400, 650, njl. Ixabiso elibalwe ngokufanelekileyo linani lokwenyani. Umzekelo 325.4 u In. Xa umakhi esebenzisa iMoody Method yokubala, kwaye ingcali ibala amaxabiso ngesandla, kufuneka ufumane amaphepha asibhozo eekhompyutha kunye neploti ye-isometric. Iploti ye-isometric ibonisa ukuphakama okwahlukeneyo kwimigca eyahlukeneyo kunye nokuba umgama ongakanani owahlula iindawo ezikhethiweyo ezidibanayo.

Umfanekiso 3(Kuthatha amaphepha asibhozo anje ukubala ukuba tyaba ngesandla. Qiniseka ukuba ubuza ukuba kutheni ungafumani oku ukuba umakhi wakho usebenzisa i-autocollimation!)

Umfanekiso 4

Iingcali zeDimensional Gauge zisebenzisa amanqanaba omahluko (Umfanekiso 4) njengezixhobo ezikhethwayo ukulinganisa utshintsho lwemizuzu kwi-angularity ukusuka kwisikhululo sokulinganisa ukuya kwisikhululo. Amanqanaba anesisombululo esisezantsi ukuya kwimizuzwana ye-.1 arc (5 u Inchs usebenzisa i-sled eyi-4″) azinzile kakhulu, awachaphazeleki kukungcangcazela, imigama elinganisiweyo, imisinga yomoya, ukudinwa komqhubi, ungcoliseko lomoya okanye naziphi na iingxaki ezikhoyo kwezinye izixhobo. Yongeza uncedo lwekhompyutha, kwaye umsebenzi uba ngokukhawuleza, uvelisa iiploti ze-topographical kunye ne-isometric ezibonisa ukuqinisekiswa kwaye okubaluleke kakhulu ukulungiswa.

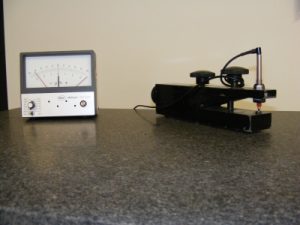

Uvavanyo oluLungileyo lokuPhinda-phinda

Uvavanyo oluphindaphindwayo okanye oluphindaphindwayo lolona lubalulekileyo. Izixhobo esizisebenzisayo ukwenza uvavanyo oluphindaphindwayo sisixhobo sokufunda esiphindaphindwayo, i-LVDT kunye ne-amplifier efunekayo ekufundeni okunesisombululo esiphezulu. Sibeka i-amplifier ye-LVDT kwisisombululo esincinci se-10 u Inchs okanye i-5 u Inchs kwiipleyiti zokuchaneka okuphezulu.

Ukusebenzisa isalathisi somatshini esinesisombululo se-20 u Inch kuphela akunamsebenzi ukuba uzama ukuvavanya imfuneko yokuphinda-phinda ye-35 u Inch. Izalathisi zinokungaqiniseki kwe-40 u Inch! Ukuseta ukuphinda-phinda kokufunda kulingisa igeyiji yokuphakama/ulungiselelo lwenxalenye.

Ukuphinda-phinda AKUFANI nokuba tyaba ngokubanzi (iMean Plane). Ndithanda ukucinga ngokuphinda-phinda kwi-granite okubonwa njengomlinganiselo we-radius ohambelanayo.

Umfanekiso 5

Ukuba uvavanya ukuba ibhola engqukuva iyaphinda-phinda na, ubonise ukuba i-radius yebhola ayitshintshanga. (Iprofayili efanelekileyo yepleyiti elungisiweyo kakuhle inesimo esinomqhele ojijekileyo.) Nangona kunjalo, kuyacaca ukuba ibhola ayithe tyaba. Ewe, ngandlela ithile. Kumgama omfutshane kakhulu, ithe tyaba. Ekubeni uninzi lomsebenzi wokuhlola lubandakanya igeyiji yokuphakama kufutshane kakhulu nenxalenye, ukuphindaphindeka kuba yeyona nto ibalulekileyo kwipleyiti yegranite. Kubaluleke ngakumbi ukuba ithe tyaba iyonke ngaphandle kokuba umsebenzisi ujonga ukuthe tye kwenxalenye ende.

Qinisekisa ukuba umenzi-sicelo wakho wenza uvavanyo lokufunda oluphindaphindwayo. Ipleyiti inokuba nokufundwa okuphindaphindayo kakhulu ngenxa yokunyamezela kodwa isaphumelela uvavanyo lokuba sicaba! Okumangalisayo kukuba ilebhu inokufumana imvume kuvavanyo olungabandakanyi uvavanyo lokufunda oluphindaphindwayo. Ilebhu engakwaziyo ukulungisa okanye engoyiyo kakuhle ekulungiseni ikhetha ukwenza uvavanyo lokuba sicaba kuphela. Ukucaba akusoloko kutshintsha ngaphandle kokuba uhambisa ipleyiti.

Uvavanyo lokufunda oluphindaphindwayo lolona lulula ukuluvavanya kodwa lolona lunzima ukulufikelela xa ulapha. Qinisekisa ukuba umenzi-sicelo wakho unokubuyisela ukuphinda-phinda ngaphandle "kokuphosa" umphezulu okanye ukushiya amaza kumphezulu.

Uvavanyo lweDelta T

Olu vavanyo lubandakanya ukulinganisa ubushushu obuQINISEKILEYO belitye kumphezulu walo kunye nomphezulu walo ongezantsi kunye nokubala umahluko, iDelta T, ukuze kunikwe ingxelo ngesatifikethi.

Kubalulekile ukwazi ukuba i-coefficient ephakathi yokwandiswa kobushushu kwi-granite yi-3.5 uIn/Inch/degree. Impembelelo yamaqondo obushushu kunye nokufuma kwi-granite plate ayinamsebenzi. Nangona kunjalo, i-surface plate inokuphelelwa ngamandla okanye ngamanye amaxesha iphucuke nokuba ikwi-.3 – .5 degrees F Delta T. Kubalulekile ukwazi ukuba i-Delta T ingaphakathi kwe-.12 degrees F apho umahluko uvela khona kwi-calibration yokugqibela.

Kubalulekile ukwazi ukuba umphezulu womsebenzi weepleyiti ufudukela kubushushu. Ukuba ubushushu obuphezulu bushushu kunobuphantsi, umphezulu unyuka. Ukuba umphantsi ushushu, into engaqhelekanga, umphezulu uyancipha. Akwanelanga ukuba umphathi womgangatho okanye ingcali yazi ukuba ipleyiti ithe tyaba kwaye iphinda-phindeka ngexesha lokulungiswa okanye ukulungiswa kodwa ukuba yayiyiDelta T ngexesha lovavanyo lokugqibela lokulinganisa. Kwiimeko ezinzima umsebenzisi unokulinganisa iDelta T ngokwakhe, ukufumanisa ukuba ipleyiti ayinyamezelanga ngenxa yokutshintsha kweDelta T kuphela. Ngethamsanqa, igranite ithatha iiyure ezininzi okanye iintsuku ukuqhelana nokusingqongileyo. Ukutshintsha okuncinci kobushushu obuphakathi emini akuyi kuyichaphazela. Ngenxa yezi zizathu, asixeli ubushushu obuphakathi okanye ukufuma kuba iziphumo azinamsebenzi.

Ukunxitywa kwePlate yeGranite

Nangona igranite ilukhuni kuneepleyiti zentsimbi, igranite isakhula amabala aphantsi kumphezulu. Ukunyakaza okuphindaphindiweyo kweenxalenye kunye neegeyiji kwipleyiti yomphezulu yeyona nto ibangela ukuguguleka, ingakumbi ukuba indawo enye isetyenziswa rhoqo. Uthuli olungcolileyo nolucocayo oluvunyelweyo ukuba luhlale kumphezulu wepleyiti lukhawulezisa inkqubo yokuguguleka njengoko lungena phakathi kweenxalenye okanye iigeyiji kunye nomphezulu wegranite. Xa uhambisa iinxalenye kunye neegeyiji kumphezulu wayo, uthuli olurhabaxa ludla ngokuba yimbangela yokuguguleka okongeziweyo. Ndicebisa kakhulu ukucoca rhoqo ukunciphisa ukuguguleka. Sibone ukuguguleka kweepleyiti okubangelwa kukuhanjiswa kwemihla ngemihla kweepakeji ze-UPS ezibekwe phezu kweepleyiti! Ezo ndawo zokuguguleka zichaphazela ukufundwa kovavanyo lokuphindaphindwa kokulinganisa. Kuphephe ukuguguleka ngokucoca rhoqo.

Ukucocwa kwePlate yeGranite

Ukuze ugcine ipleyiti icocekile, sebenzisa ilaphu elincamathelayo ukususa uthuli. Cinezela nje kancinci, ukuze ungashiyi intsalela yeglue. Ilaphu elinamathelayo elisetyenziswe kakuhle lenza umsebenzi omhle wokususa uthuli olusilayo phakathi kokucoca. Musa ukusebenza kwindawo enye. Hambisa iseti yakho ujikeleze ipleyiti, usasaze ukuguguleka. Kulungile ukusebenzisa utywala ukucoca ipleyiti, kodwa qaphela ukuba ukwenza njalo kuya kuyipholisa kakhulu indawo okwethutyana. Amanzi anesepha encinci alungile kakhulu. Izicoci ezithengiswayo ezifana nesicoci sikaStarrett nazo zilungile ukuzisebenzisa, kodwa qiniseka ukuba ususa yonke intsalela yesepha phezu kwayo.

Ukulungiswa kwePleyiti yeGranite

Kuya kufuneka kucace ngoku ukubaluleka kokuqinisekisa ukuba umenzi wepleyiti yakho yomphezulu wenza uhlengahlengiso olufanelekileyo. Iilebhu zohlobo lwe-“Clearing House” ezibonelela ngeenkqubo ze-“Do it all with one call” azinazo ingcali enokwenza ulungiso. Nokuba zibonelela ngolungiso, azinazo rhoqo ingcali enamava afunekayo xa ipleyiti yomphezulu ingasakwazi ukunyamezela.

Ukuba uxelelwe ukuba ipleyiti ayinakulungiswa ngenxa yokonakala kakhulu, sitsalele umnxeba. Kusenokwenzeka ukuba singayilungisa.

Iingcali zethu zobugcisa zisebenza unyaka omnye ukuya komnye onesiqingatha phantsi kweNgcali yePlate yoMgangatho oPhezulu. Sichaza iNgcali yePlate yoMgangatho oPhezulu njengomntu ogqibile uqeqesho lwakhe kwaye unamava angaphezu kweminyaka elishumi eyongezelelweyo kwi-Surface Plate calibration and Repair. Thina kwa-Dimensional Gauge sinabasebenzi abathathu abangooNgcali abaPhezulu abanamava angaphezu kweminyaka engama-60 xa bedibene. Omnye weNgcali yethu oPhezulu uyafumaneka ngamaxesha onke ukuze anike inkxaso kunye nesikhokelo xa kuvela iimeko ezinzima. Bonke ooNgcali bethu banamava ekulinganisweni kweepleyiti zomphezulu zazo zonke iisayizi, ukusuka kwezincinci ukuya kwezinkulu kakhulu, iimeko ezahlukeneyo zendalo, amashishini ahlukeneyo, kunye neengxaki zokuguguleka okukhulu.

IiFed Specs zinomlinganiselo othile wokugqiba we-16 ukuya kwi-64 Average Arithmetic Roughness (AA). Sikhetha ukugqiba okuphakathi kwe-30-35 AA. Kukho uburhabaxa obaneleyo ukuqinisekisa ukuba iindawo kunye neegeyiji zihamba kakuhle kwaye azinamatheli okanye zijijeke kwipleyiti yomphezulu.

Xa silungisa sihlola ipleyiti ukuba ifakelwe kakuhle kwaye ilungile. Sisebenzisa indlela yokuleqa eyomileyo, kodwa kwiimeko zokuguguleka kakhulu ezifuna ukususwa okukhulu kwegranite, siyayimanzisa imijikelo. Iingcali zethu ziyazicoca, zicocekile, zikhawuleza kwaye zichanekile. Oko kubalulekile kuba iindleko zenkonzo yepleyiti yegranite ziquka ixesha lakho lokungasebenzi kunye nokulahleka kwemveliso. Ukulungiswa okufanelekileyo kubaluleke kakhulu, kwaye akufuneki ukhethe umakhi ngokwexabiso okanye ngokulula. Eminye imisebenzi yokulinganisa ifuna abantu abaqeqeshwe kakhulu. Sinayo loo nto.

Iingxelo zokugqibela zoLungiso

Kwindawo nganye yokulungisa nokulinganisa ipleyiti yomphezulu, sinikezela ngeengxelo zobungcali ezineenkcukacha. Iingxelo zethu ziqulethe ulwazi oluninzi olubalulekileyo nolufanelekileyo. I-Fed Spec. ifuna uninzi lolwazi esilunikileyo. Ngaphandle kwezo ziqulathwe kweminye imigangatho yomgangatho efana ne-ISO/IEC-17025, ubuncinci be-Fed. Iinkcukacha zeengxelo zezi:

- Ubungakanani kwi-Ft. (X' x X')

- Umbala

- Uhlobo (Alubhekiseli kwiintambo ezibambekayo okanye iintambo ezimbini okanye ezine)

- I-Modulus eQikelelweyo ye-Elasticity

- Ukunyamezelana Okuphakathi Kweendiza (Kumiselwa yiBanga/Ubungakanani)

- Ukuphinda ufunde Ukunyamezela (Kumiselwa bubude obu-diagonal ngee-intshi)

- I-Mean Plane njengoko ifunyenwe

- I-Mean Plane njengasekhohlo

- Phinda ufunde njengoko kufunyenwe

- Phinda ufunde njengoko kusekhohlo

- I-Delta T (Umahluko wobushushu phakathi komphezulu nowasezantsi)

Ukuba ingcali kufuneka yenze umsebenzi wokulungisa okanye wokulungisa ipleyiti yomphezulu, isatifikethi sokulinganisa sihamba nesicwangciso sendawo okanye se-isometric ukubonisa ukulungiswa okusebenzayo.

Ilizwi malunga ne-ISO/IEC-17025 Accreditations kunye neelabhoratri ezinazo

Ukuba nje ilebhu iqinisekisiwe ekulinganisweni kwepleyiti yomphezulu akuthethi ukuba bayayazi into abayenzayo, ingasathethwa ke ngokuyenza ngokuchanekileyo! Kananjalo akuthethi ukuba ilebhu inokukwazi ukuyilungisa. Amaqumrhu agunyazisayo awahluli phakathi kokuqinisekisa okanye ukulungisa.ANdiyazi enye, mhlawumbi2ukuvuma amaqumrhu azaLiqhinaAiribhoni ijikeleze inja yam ukuba ndingayihlawula imali eyaneleyo! Liyinyaniso ebuhlungu. Ndibone iilabhoratri zifumana isiqinisekiso ngokwenza uvavanyo olunye kuphela kwezithathu ezifunekayo. Ngaphezu koko, ndibone iilabhoratri zifumana isiqinisekiso ngaphandle kokungaqiniseki okungenakwenzeka kwaye zifumana isiqinisekiso ngaphandle kobungqina okanye umboniso wokuba zibale njani amaxabiso. Konke oku kulishwa.

Uqulunqo

Awunakuyithatha kancinci indima yeepleyiti zegranite ezichanekileyo. Isalathiso esithe tyaba esibonelelwa ziipleyiti zegranite sisiseko apho wenza khona zonke ezinye izilinganiso.

Ungasebenzisa izixhobo zokulinganisa zanamhlanje, ezichanekileyo nezisebenziseka lula. Nangona kunjalo, ukulinganisa ngokuchanekileyo kunzima ukuqiniseka ukuba umphezulu wereferensi awuthe tyaba. Ngesinye isihlandlo, ndafumana umthengi oza kuba ngumthengi esithi kum “kulungile, lilitye nje!” Impendulo yam, “Kulungile, uchanekile, kwaye ngokuqinisekileyo awunakuthethelela ukuba neengcali zize kulungisa iipleyiti zakho zomphezulu.”

Ixabiso alisosizathu silungileyo sokukhetha abakhi beepleyiti zomphezulu. Abathengi, abagcini-zincwadi kunye nenani eliphazamisayo leenjineli ezisemgangathweni abasoloko beqonda ukuba ukuphinda ugcwalise iipleyiti zegranite akufani nokuphinda ugcwalise i-micrometer, i-caliper okanye i-DMM.

Ezinye izixhobo zifuna ubuchule, hayi ixabiso eliphantsi. Emva kokutsho oko, amaxabiso ethu afanelekile kakhulu. Ingakumbi ukuze sibe nokuzithemba ukuba senza umsebenzi ngokuchanekileyo. Sidlula ngaphaya kweemfuno ze-ISO-17025 kunye neeNkcukacha zeSizwe ngexabiso elongezelelweyo.

Iipleyiti zomphezulu zisisiseko semilinganiselo emininzi, kwaye ukunyamekela ngokufanelekileyo ipleyiti yakho yomphezulu kuyimfuneko ukuqinisekisa ukuchaneka komlinganiselo.

I-granite yeyona nto idumileyo esetyenziselwa iipleyiti zomphezulu ngenxa yeempawu zayo ezibonakalayo ezifanelekileyo, ezinje ngokuqina komphezulu kunye nobuthathaka obuphantsi bokuguquguquka kobushushu. Nangona kunjalo, xa ipleyiti zomphezulu zisetyenziswa rhoqo, ziyawohloka.

Ukuthe tyaba kunye nokuphindaphindwa kwezinto zombini ziinkalo ezibalulekileyo ekumiseleni ukuba ipleyiti inika umphezulu ochanekileyo wokufumana imilinganiselo echanekileyo. Ukunyamezelana kwezi nkalo zombini kuchazwa phantsi kweFederal Specification GGG-P-463C, DIN, GB, JJS... Ukuthe tyaba kukulinganisa umgama phakathi kweyona ndawo iphakamileyo (uphahla) kunye neyona ndawo iphantsi (umgangatho osisiseko) kwipleyiti. Ukuphindaphinda kumisela ukuba umlinganiselo othathwe kwindawo enye unokuphinda uphindwe kuyo yonke ipleyiti ngaphakathi kokunyamezelana okuchaziweyo. Oku kuqinisekisa ukuba akukho zincopho okanye iintlambo kwipleyiti. Ukuba ukufundwa akukho ngaphakathi kwezikhokelo ezichaziweyo, ke ukuphinda umphezulu kunokufuneka ukubuyisela imilinganiselo kwimimiselo.

Ukulinganiswa kwepleyiti yomphezulu rhoqo kuyimfuneko ukuqinisekisa ukuba ithe tyaba kwaye iyaphindaphindeka ngokuhamba kwexesha. Iqela lokulinganisa ngokuchanekileyo eCross livunyiwe yi-ISO 17025 ukulinganisa ukuthamba kunye nokuphindaphinda kwepleyiti yomphezulu. Sisebenzisa iNkqubo yeSatifikethi sePlate yeMahr Surface equka:

- Uhlalutyo lweMoody kunye neProfayili,

- Iiploti ze-Isometric okanye zeNumeric,

- I-avareji yokubaleka okuninzi, kunye

- Ukubeka Iigreyidi Ngokuzenzekelayo NgokweMigangatho yoShishino.

Imodeli yoNcedo lweKhompyutha iMahr imisela naluphi na uphambuko lwe-angular okanye olu-linear ukusuka kwinqanaba elipheleleyo, kwaye ifanelekile kakhulu ekucwangcisweni ngokuchanekileyo kweepleyiti zomphezulu.

Amathuba phakathi kokulinganiswa aya kwahluka ngokuxhomekeke kwinani lokusetyenziswa, iimeko zokusingqongileyo apho ipleyiti ikhoyo, kunye neemfuno ezithile zomgangatho wenkampani yakho. Ukugcina ipleyiti yakho yomphezulu ngokufanelekileyo kunokuvumela amaxesha amade phakathi kokulinganiswa ngakunye, kukunceda uphephe iindleko ezongezelelweyo zokuphinda udibanise, kwaye okubaluleke kakhulu kuqinisekisa ukuba imilinganiselo oyifumanayo kwipleyiti ichanekile kangangoko kunokwenzeka. Nangona iipleyiti zomphezulu zibonakala ziqinile, zizixhobo ezichanekileyo kwaye kufuneka ziphathwe ngolo hlobo. Nazi ezinye izinto ekufuneka uziqwalasele malunga nokunyamekela iipleyiti zakho zomphezulu:

- Gcina ipleyiti icocekile, kwaye ukuba kunokwenzeka uyigqume xa ingasetyenziswa

- Akukho nto ifanele ibekwe epleyitini ngaphandle kweegeyiji okanye iziqwenga eziza kulinganiswa.

- Musa ukusebenzisa indawo enye kwipleyiti ngalo lonke ixesha.

- Ukuba kunokwenzeka, jikelezisa ipleyiti rhoqo.

- Hlonipha umda womthwalo wepleyiti yakho

Isiseko seGranite esichanekileyo sinokuphucula ukusebenza kwezixhobo zomatshini

Iimfuno ziyaqhubeka zisanda kubunjineli boomatshini ngokubanzi kwaye ngokukodwa kulwakhiwo lwezixhobo zoomatshini. Ukufikelela kubuchule obuphezulu kunye namaxabiso okusebenza ngaphandle kokunyusa iindleko yimingeni eqhubekayo yokuba nobuchule bokukhuphisana. Ibhedi yezixhobo zoomatshini yinto ebalulekileyo apha. Ke ngoko, abavelisi bezixhobo zoomatshini abaninzi baxhomekeke kwi-granite. Ngenxa yeempawu zayo ezibonakalayo, inika iingenelo ezicacileyo ezingenakufunyanwa ngentsimbi okanye ikhonkrithi yepolymer.

I-Granite lilitye elibizwa ngokuba lilitye elinzulu lentaba-mlilo kwaye linesakhiwo esixineneyo nesifanayo esine-coefficient ephantsi kakhulu yokwandiswa, i-thermal conductivity ephantsi kunye ne-vibration damping ephezulu.

Apha ngezantsi uza kufumanisa ukuba kutheni uluvo oluqhelekileyo lokuba i-granite ifaneleka kuphela njengesiseko somatshini kwiimashini zokulinganisa ii-coordinate eziphezulu luphelelwe lixesha kwaye kutheni le nto le nto yendalo njengesiseko sesixhobo somatshini iyindlela enenzuzo kakhulu endaweni yentsimbi okanye isinyithi esityhidiweyo nakwizixhobo zomatshini ezichanekileyo.

Singavelisa izinto zegranite zokunyakaza okunamandla, izinto zegranite zeemoto ezithe nkqo, izinto zegranite ze-ndt, izinto zegranite ze-xray, izinto zegranite ze-cmm, izinto zegranite ze-cnc, ukuchaneka kwegranite kwelaser, izinto zegranite zeenqwelo moya, izinto zegranite zezigaba zokuchaneka...

Ixabiso Elongezelelweyo Eliphezulu Ngaphandle Kweendleko Ezongezelelweyo

Ukusetyenziswa okwandayo kwegranite kubunjineli boomatshini akubangelwanga kangako kukunyuka okukhulu kwexabiso lentsimbi. Kunoko, kungenxa yokuba ixabiso elongezelelweyo lesixhobo somatshini esifunyenwe ngomatshini owenziwe ngegranite linokwenzeka ngexabiso elincinci kakhulu okanye akukho zindleko zongezelelweyo. Oku kungqinwa kukuthelekiswa kweendleko zabavelisi bezixhobo zoomatshini abaziwayo eJamani naseYurophu.

Ukwanda okukhulu kozinzo lwe-thermodynamic, ukudambisa ukungcangcazela kunye nokuchaneka kwexesha elide okwenziwa yi-granite akunakufikelelwa ngebhedi yentsimbi ephosiweyo okanye yentsimbi, okanye ngexabiso eliphezulu kuphela. Umzekelo, iimpazamo zobushushu zinokubalelwa ukuya kuthi ga kwi-75% yempazamo iyonke yomatshini, kunye nokuhlawula okuhlala kujongwa yisoftware - ngempumelelo ephakathi. Ngenxa yokuqhuba kwayo ubushushu obuphantsi, i-granite sisiseko esingcono sokuchaneka kwexesha elide.

Ngokunyamezela kwe-1 μm, igranite ihlangabezana ngokulula neemfuno zokuthamba ngokwe-DIN 876 kwinqanaba lokuchaneka kwe-00. Ngexabiso le-6 kwisikali sobunzima ukusuka ku-1 ukuya ku-10, iqinile kakhulu, kwaye ngobunzima bayo obuthile be-2.8g/cm³ phantse ifikelele kwixabiso le-aluminium. Oku kukwakhokelela kwiingenelo ezongezelelweyo ezifana namazinga aphezulu okutya, ukukhawuleziswa okuphezulu kwe-axis kunye nokwandiswa kobomi besixhobo sezixhobo zokusika izixhobo zomatshini. Ngoko ke, utshintsho ukusuka kwibhedi ye-cast ukuya kwibhedi yomatshini we-granite luhambisa isixhobo somatshini esithethwayo kwiklasi ephezulu ngokubhekiselele ekuchanekeni nasekusebenzeni - ngaphandle kweendleko ezongezelelweyo.

Isiseko seGranite esiphuculweyo seNdalo

Ngokungafaniyo nezinto ezifana nentsimbi okanye isinyithi esityhidiweyo, amatye endalo akufuneki aveliswe ngamandla amaninzi kwaye asetyenziswe izongezo. Kufuneka amandla amancinci kuphela xa kusenziwa imigodi kunye nokulungiswa komphezulu. Oku kubangela ukuba kubekho unyawo oluphezulu lwendalo, oluthi nasekupheleni kobomi bomatshini ludlule olo lwentsimbi njengezinto. Ibhedi yegranite inokuba sisiseko somatshini omtsha okanye isetyenziswe kwiinjongo ezahlukeneyo ngokupheleleyo ezifana nokuqhekeza ukwakhiwa kwendlela.

Akukho kunqongophala kwezixhobo zegranite. Lilitye elinzulu elenziwe nge-magma ngaphakathi koqweqwe lomhlaba. Liye 'lavuthwa' kangangezigidi zeminyaka kwaye lifumaneka ngobuninzi kakhulu njengomthombo wendalo phantse kuwo onke amazwekazi, kuquka lonke elaseYurophu.

Isiphelo: Iingenelo ezininzi ezibonakalayo zegranite xa kuthelekiswa nentsimbi okanye isinyithi esityhidiweyo ziqinisekisa ukuzimisela okwandayo kweenjineli zoomatshini ukusebenzisa le nto yendalo njengesiseko sezixhobo zoomatshini ezichanekileyo nezisebenza kakuhle. Ulwazi oluneenkcukacha malunga neempawu zegranite, eziluncedo kwizixhobo zoomatshini kunye nobunjineli boomatshini, lunokufumaneka kweli nqaku lilandelayo.

Umlinganiselo ophindaphindwayo kukulinganisa iindawo ezithe tyaba zasekuhlaleni. Inkcazo yoMlinganiselo oPhindwayo ithi umlinganiselo othathwe naphi na kumphezulu wepleyiti uya kuphinda ngaphakathi komlinganiselo ochaziweyo. Ukulawula ukuthe tyaba kwendawo yasekuhlaleni ngaphezu kokuthe tyaba ngokubanzi kuqinisekisa utshintsho oluthe ngcembe kwiprofayili yokuthe tyaba yomphezulu ngaloo ndlela kunciphisa iimpazamo zasekuhlaleni.

Uninzi lwabavelisi, kuquka neebhrendi ezingeniswe kwamanye amazwe, balandela i-Federal Specification of whole flatness tolerances kodwa abaninzi abayinaki imilinganiselo ephindaphindwayo. Uninzi lweepleyiti zexabiso eliphantsi okanye ezingabizi kakhulu ezikhoyo kwimarike namhlanje aziyi kuqinisekisa imilinganiselo ephindaphindwayo. Umenzi ongaqinisekisi imilinganiselo ephindaphindwayo AKAZENZI iipleyiti ezihlangabezana neemfuno ze-ASME B89.3.7-2013 okanye i-Federal Specification GGG-P-463c, okanye i-DIN 876, GB, JJS...

Zombini zibalulekile ukuqinisekisa umphezulu ochanekileyo ukuze kulinganiswe ngokuchanekileyo. Inkcazo yokuthambeka yodwa ayanelanga ukuqinisekisa ukuchaneka komlinganiselo. Umzekelo, ipleyiti yomphezulu ye-36 X 48 Inspection Grade A, ehlangabezana kuphela nenkcazo yokuthambeka ye-.000300". Ukuba isiqwenga esijongiweyo sihlanganisa iincopho ezininzi, kwaye igeyiji esetyenziswayo ikwindawo ephantsi, impazamo yokulinganisa inokuba kukunyamezelana okupheleleyo kwindawo enye, i-000300". Enyanisweni, inokuba phezulu kakhulu ukuba igeyiji iphumle kwithambeka lentaba.

Iimpazamo ze-.000600"-.000800" zinokwenzeka, kuxhomekeke kubunzima bomthambeka, kunye nobude bengalo yegeji esetyenziswayo. Ukuba le pleyiti ibine-Repeat Measurement specification ye-.000050"FIR ngoko impazamo yokulinganisa ibiya kuba ngaphantsi kwe-.000050" nokuba ithatha phi imilinganiselo kwipleyiti. Enye ingxaki, edla ngokuvela xa ingcali engaqeqeshwanga izama ukuphinda ifake ipleyiti kwindawo, kukusebenzisa i-Repeat Measurements kuphela ukuqinisekisa ipleyiti.

Izixhobo ezisetyenziselwa ukuqinisekisa ukuphindaphindwa kwazo AZIYENZIWA ukujonga ukuthe tyaba ngokubanzi. Xa zibekwe ku-zero kumphezulu ogobileyo ngokugqibeleleyo, ziya kuqhubeka zifunda u-zero, nokuba loo mphezulu uthe tyaba ngokugqibeleleyo okanye ugobile ngokugqibeleleyo okanye ujijekile nge-1/2"! Ziqinisekisa nje ukufana komphezulu, hayi ukuthe tyaba. Yipleyiti kuphela ehlangabezana nenkcazo yokuthe tyaba KUNYE nenkcazo yokulinganisa okuphindaphindwayo ehlangabezana neemfuno ze-ASME B89.3.7-2013 okanye i-Federal Specification GGG-P-463c.

Ask us about or flatness specification and repeat measurement promise by calling +86 19969991659 or emailing INFO@ZHHIMG.COM

Ewe, kodwa zinokuqinisekiswa kuphela nge-gradient ethile yobushushu ethe nkqo. Iziphumo zokwanda kobushushu kwipleyiti zinokubangela utshintsho oluchanekileyo ngaphezu kokunyamezela ukuba kukho utshintsho kwi-gradient. Kwezinye iimeko, ukuba ukunyamezela kuqinile ngokwaneleyo, ubushushu obufunxwe kukukhanya okuphezulu bunokubangela utshintsho olwaneleyo lwe-gradient kwiiyure ezininzi.

I-Granite inomlinganiselo wokwanda kobushushu obumalunga ne-.0000035 intshi nge-intshi nganye kwi-1°F. Umzekelo: Ipleyiti yomphezulu eyi-36" x 48" x 8" inomchaneko we-.000075" (1/2 yeGrade AA) kwi-gradient ye-0°F, umphezulu kunye nomzantsi zibushushu obufanayo. Ukuba umphezulu wepleyiti ufudumala ude ufikelele kwinqanaba apho ubushushu buyi-1°F kunomzantsi, ukuchaneka kuya kutshintsha kube yi-.000275" engqukuva! Ke ngoko, uku-odola ipleyiti enokunyamezela okuqinileyo kuneLaboratory Grade AA kufuneka kuqwalaselwe kuphela ukuba kukho ulawulo olufanelekileyo lwemozulu.

Ipleyiti yomphezulu kufuneka ixhaswe kwiindawo ezi-3, okungcono ukuba ibekwe kwi-20% yobude ukusuka eziphelweni zepleyiti. Izixhasi ezibini kufuneka zibekwe kwi-20% yobubanzi ukusuka kumacala amade, kwaye inkxaso eseleyo mayibe phakathi. Ziindawo ezi-3 kuphela ezinokusekelwa ngokuqinileyo kuyo nayiphi na into ngaphandle komphezulu ochanekileyo.

Ipleyiti kufuneka ixhaswe kwezi ndawo ngexesha lokuveliswa, kwaye kufuneka ixhaswe kuphela kwezi ndawo zintathu ngelixa isetyenziswa. Ukuzama ukuxhasa ipleyiti kwiindawo ezingaphezu kwezintathu kuya kubangela ukuba ipleyiti ifumane inkxaso yayo kwiindidi ezahlukeneyo zamanqaku amathathu, ezingayi kuba ngamanqaku amathathu afanayo apho yayixhaswe khona ngexesha lokuveliswa. Oku kuya kubangela iimpazamo njengoko ipleyiti ijika ukuze ihambelane nolungiselelo olutsha lwenkxaso. Zonke izitendi zentsimbi ze-zhhimg zinemiqadi yokuxhasa eyenzelwe ukuhambelana neendawo ezifanelekileyo zokuxhasa.

Ukuba ipleyiti ixhaswe ngokufanelekileyo, ukulinganisa ngokuchanekileyo kuyimfuneko kuphela ukuba isicelo sakho sifuna oko. Ukulinganisa ngokuchanekileyo akufuneki ukuze kugcinwe ukuchaneka kwepleyiti exhaswe ngokufanelekileyo.

Kutheni Ukhetha iGraniteIziseko zoomatshinikwayeIzinto zeMetrology?

Impendulo ithi 'ewe' phantse kuyo yonke into esetyenziswayo. Iingenelo zegranite ziquka: Akukho mhlwa okanye ukugqwala, phantse azinakugoba, akukho qhuma lihlawulayo xa lityunyuziwe, lihlala ixesha elide, lisebenza kakuhle, lichaneke ngakumbi, alisebenzisi magnethi kangako, alisebenzi kakuhle xa likhula ngobushushu, kwaye liphantsi iindleko zokulungisa.

I-Granite luhlobo lwelitye elitshisiweyo elimbiwa ngenxa yamandla alo agqithisileyo, ubuninzi, ukuqina, kunye nokumelana nokugqwala. Kodwa i-granite ikwanokuguquguquka kakhulu- ayisiyoyezikwere kunye neengxande kuphela! Enyanisweni, iStarrett Tru-Stone isebenza ngokuzithemba nezixhobo ze-granite ezakhiwe ngokweemilo, ii-engile, kunye nee-curves zazo zonke iintlobo rhoqo-ngeziphumo ezigqwesileyo.

Ngenxa yokulungiswa kwethu okusemgangathweni, iindawo ezisikiweyo zingaba tyaba kakhulu. Ezi mpawu zenza i-granite ibe yeyona nto ifanelekileyo yokwenza iziseko zoomatshini kunye nezixhobo ze-metrology ezinobukhulu obuqhelekileyo kunye noyilo oluqhelekileyo. I-Granite yile:

iyakwazi ukwenziwa ngomatshini

ngokuthe tye xa isikiwe kwaye igqityiwe

ukumelana nomhlwa

eqinileyo

ihlala ixesha elide

Izinto zegranite nazo kulula ukuzicoca. Xa usenza uyilo olukhethekileyo, qiniseka ukuba ukhetha igranite ngenxa yezibonelelo zayo ezibalaseleyo.

IMIGANGATHO/ IZICELO ZOKUNXIBA PHEZULU

I-granite esetyenziswa yiZhongHui kwiimveliso zethu zeplati zomphezulu ezisemgangathweni inomxholo ophezulu we-quartz, nto leyo enika ukumelana okukhulu nokuguguleka kunye nokonakala. Imibala yethu eNkulu emnyama kunye neCrystal Pink inezinga eliphantsi lokufunxwa kwamanzi, nto leyo enciphisa amathuba okuba ii-geji zakho zigrule xa zibekwe kwiiplati. Imibala yegranite enikezelwa yiZhongHui ibangela ukukhanya okuncinci, nto leyo ethetha ukuba amehlo angaphantsi kubantu abasebenzisa iiplati. Sikhethe iintlobo zethu zegranite ngelixa sicinga ngokwandiswa kobushushu ukuze sigcine olu phawu luncinci.

ISICELO ESISEKELWEYO

Xa usetyenziso lwakho lufuna ipleyiti enemilo eyenzelwe wena, izinto ezifakwe imisonto, iindawo zokufaka okanye ezinye izinto zokulungisa, kuya kufuneka ukhethe izinto ezifana neBlack Diabase. Ezi zinto zendalo zinika ukuqina okuphezulu, ukudambisa ukungcangcazela okugqwesileyo, kunye nokuphucula ukusebenza koomatshini.

Ewe, ukuba azigugi kakhulu. Ukuseta kwethu ifektri kunye nezixhobo kuvumela iimeko ezifanelekileyo zokulinganisa ipleyiti ngokufanelekileyo kunye nokulungiswa kwakhona ukuba kuyimfuneko. Ngokubanzi, ukuba ipleyiti ikwi-.001" yokunyamezela okufunekayo, inokuphinda ibekwe kwindawo yayo. Ukuba ipleyiti igugiwe yada yafikelela kwinqanaba apho ingaphezulu kwe-.001" yokunyamezela, okanye ukuba inemingxuma okanye ikrwelwe kakubi, kuya kufuneka ithunyelwe efektri ukuze igrunjwe ngaphambi kokuba iphinde igrunjwe.

Kufuneka kusetyenziswe unonophelo olukhulu xa kukhethwa ingcali yokulinganisa nokulungisa umphezulu kwindawo leyo. Siyakukhuthaza ukuba uqaphele xa ukhetha inkonzo yakho yokulinganisa. Cela imvume kwaye uqinisekise ukuba izixhobo eziza kusetyenziswa yingcali zine-National Inspection Institution enokulandelelana. Kuthatha iminyaka emininzi ukufunda indlela yokurhangqa i-granite echanekileyo.

I-ZhongHui inika utshintsho olukhawulezileyo kwiindlela zokulinganisa ezenziwa kumzi-mveliso wethu. Thumela iipleyiti zakho ukuze zilinganiswe ukuba kunokwenzeka. Umgangatho kunye nodumo lwakho luxhomekeke ekuchanekeni kwezixhobo zakho zokulinganisa kuquka iipleyiti zomphezulu!

Iipleyiti zethu ezimnyama zinobunzima obuphezulu kakhulu kwaye ziqinile kathathu. Ke ngoko, ipleyiti eyenziwe ngomnyama akufuneki ibe nkulu njengepleyiti yegranite enobukhulu obufanayo ukuze ibe nokumelana okulinganayo okanye okukhulu nokuphambuka. Ubunzima obuncitshisiweyo buthetha ubunzima obuncinci kunye neendleko zokuthumela eziphantsi.

Lumka kwabanye abasebenzisa igranite emnyama ekumgangatho ophantsi ngobukhulu obufanayo. Njengoko kutshiwo apha ngasentla, iimpawu zegranite, njengomthi okanye isinyithi, ziyahluka ngokwezinto ezisetyenzisiweyo kunye nombala, kwaye ayisiyonto ichaza ngokuchanekileyo ukuqina, ubulukhuni, okanye ukumelana nokuguguleka. Enyanisweni, iintlobo ezininzi zegranite emnyama kunye ne-diabase zithambile kakhulu kwaye azifanelekanga ukusetyenziswa kwipleyiti yomphezulu.

Hayi. Izixhobo ezikhethekileyo kunye noqeqesho olufunekayo ukuze kusetyenziswe ezi zinto kwakhona zifuna ukuba zibuyiselwe kumzi-mveliso ukuze zilinganiswe kwaye ziphinde zisetyenziswe.

Ewe. I-ceramic kunye ne-granite zineempawu ezifanayo, kwaye iindlela ezisetyenziswayo ukulinganisa kunye nokujikeleza i-granite zingasetyenziswa nezinto ze-ceramic. I-ceramics kunzima ukuyijikeleza kune-granite nto leyo ebangela ixabiso eliphezulu.

Ewe, ukuba nje izinto ezifakelweyo zingaphantsi komphezulu. Ukuba izinto ezifakelweyo zentsimbi zigutyungelwe ngumphezulu okanye ngaphezulu, kufuneka zijonge phantsi ngaphambi kokuba ipleyiti ikwazi ukugoba. Ukuba kuyimfuneko, singayibonelela loo nkonzo.

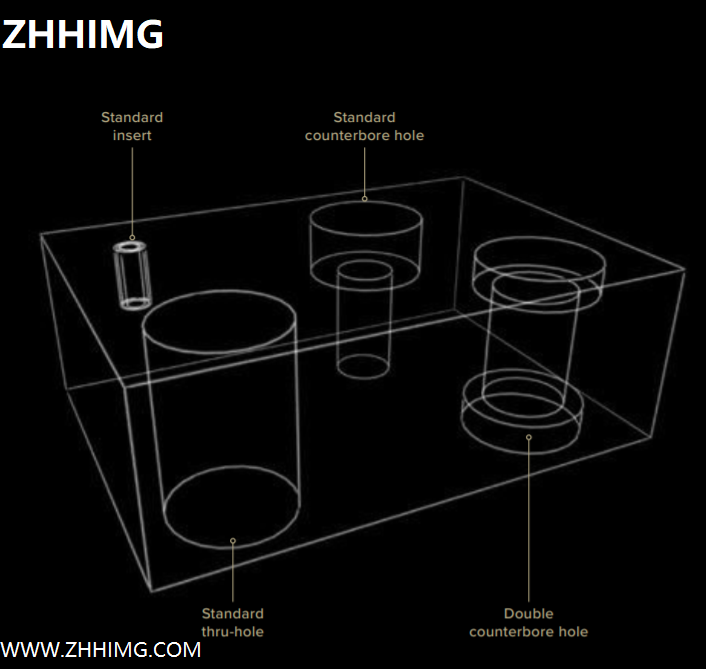

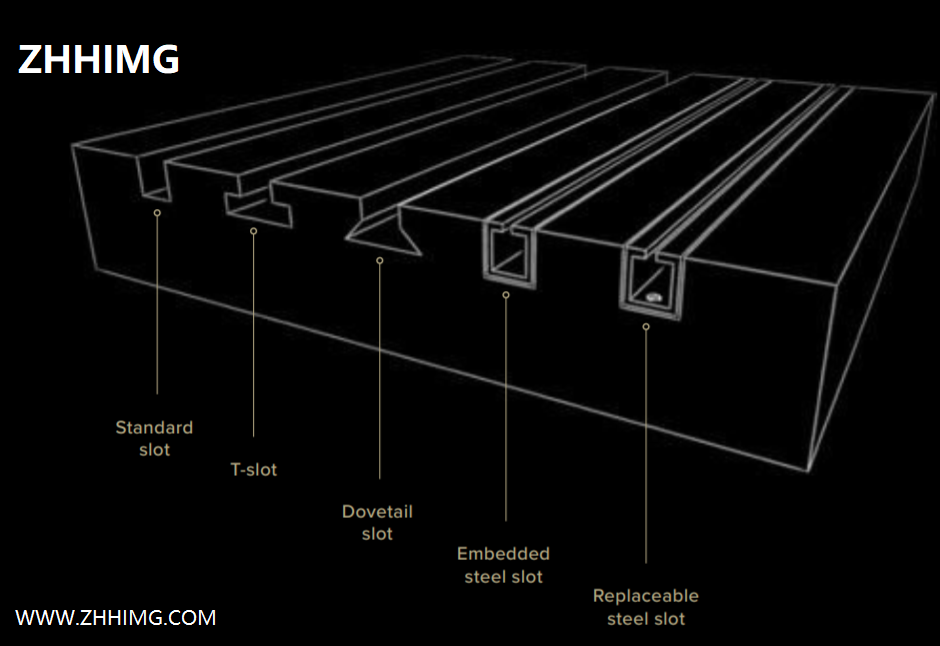

Ewe. Izinto ezifakwe ngentsimbi ezinentambo efunekayo (ngesiNgesi okanye nge-metric) zinokubotshelelwa kwipleyiti kwiindawo ezifunekayo. I-ZhongHui isebenzisa oomatshini be-CNC ukubonelela ngeendawo ezifakwe ngentsimbi eziqinileyo ngaphakathi kwe-+/- 0.005”. Kwizinto ezifakwe ngentsimbi ezingabalulekanga kangako, ukunyamezela kwethu indawo kwii-inserts ezinentambo yi-±.060". Ezinye iindlela ziquka ii-T-Bars zentsimbi kunye ne-dovetail slots ezifakwe ngqo kwi-granite.

Ii-inserts ezibotshelelwe ngokufanelekileyo kusetyenziswa i-epoxy enamandla aphezulu kunye nomsebenzi omhle ziya kumelana namandla amaninzi okujika kunye nokucheba. Kuvavanyo lwakutshanje, kusetyenziswa ii-inserts ezinemisonto ezi-3/8"-16, ilebhu yovavanyo ezimeleyo ilinganise amandla afunekayo ukutsala i-insert ene-epoxy kwipleyiti yomphezulu. Iiplate ezilishumi zavavanywa. Kula manqaku alishumi, kwiimeko ezilithoba, i-granite yaphuka kuqala. Umthwalo ophakathi kwindawo yokusilela yayiyi-10,020 lbs. kwi-granite engwevu kunye ne-12,310 lbs. kumnyama. Kwimeko enye apho i-insert itsaliwe ngaphandle kwepleyiti, umthwalo kwindawo yokusilela yayiyi-12,990 lbs.! Ukuba isiqwenga somsebenzi senza ibhuloho ngaphesheya kwe-insert kwaye kusetyenziswa i-torque egqithisileyo, kunokwenzeka ukuvelisa amandla aneleyo okuqhekeza i-granite. Ngenxa yesi sizathu, iZhongHui inika izikhokelo ze-torque ekhuselekileyo ephezulu engasetyenziswa kwii-inserts ezine-epoxy: https://www.zhhimg.com/standard-thread-inserts-product/

Ewe, kodwa kuphela kumzi-mveliso wethu. Kwifektri yethu, singabuyisela phantse nayiphi na ipleyiti kwimeko 'efana nentsha', ngesiqhelo sixabisa ngaphantsi kwesiqingatha seendleko zokuyitshintsha. Imiphetho eyonakeleyo inokulahlwa ngobuhle, imingxunya enzulu, ii-nicks, kunye nee-pits zinokucolwa, kwaye izixhasi eziqhotyoshelweyo zinokutshintshwa. Ukongeza, singayitshintsha ipleyiti yakho ukuze yonyuse ukuguquguquka kwayo ngokongeza izinto ezifakwe kwintsimbi eqinileyo okanye enemisonto kunye ne-cutting slots okanye imilebe ebambayo, ngokweemfuno zakho.

Kutheni ukhetha iGranite?

I-Granite luhlobo lwelitye eliyi-igneous elenziwe eMhlabeni kwiminyaka eyi-2000 eyadlulayo. Ukwakheka kwelitye eliyi-igneous kwakuqulathe iiminerali ezininzi ezifana ne-quartz eqinileyo kakhulu kwaye ayigugi. Ukongeza kubunzima kunye nokumelana nokugugika, i-granite inomlinganiselo wesiqingatha sokwanda njengesinyithi esityhidiweyo. Njengoko ubunzima bayo obuyi-volumetric bumalunga nesinye kwisithathu sesinyithi esityhidiweyo, i-granite kulula ukuyisebenzisa.

Kwiziseko zoomatshini kunye nezinto zemetrology, igranite emnyama yeyona mibala isetyenziswa kakhulu. Igranite emnyama inepesenti ephezulu yequartz kuneminye imibala kwaye, ngenxa yoko, yeyona igugileyo kakhulu.

Igranite ixabisa kancinci, kwaye iindawo ezisikiweyo zingaba tyaba kakhulu. Ayinakuphela nje ukuba itsalwe ngesandla ukuze kufezekiswe ukuchaneka okugqithisileyo, kodwa ukuphinda ilungiswe kungenziwa ngaphandle kokususa ipleyiti okanye itafile ngaphandle kwendawo. Ngumsebenzi wokudibanisa ngesandla kwaye ngokubanzi ubiza kancinci kakhulu kunokulungisa kwakhona enye indlela yesinyithi.

Ezi mpawu zenza i-granite ibe yeyona nto ifanelekileyo yokwenza iziseko zoomatshini ezenziwe ngokwezifiso kunye nezixhobo ze-metrology ezifanaipleyiti yomphezulu wegranite.

I-ZhongHui ivelisa iimveliso zegranite ezenziwe ngokwezifiso ezenzelwe ukuxhasa iimfuno ezithile zokulinganisa. Ezi zinto zenziwe ngokwezifiso zahlukile kwiimiphetho ethe tye toizikwere ezintathuNgenxa yendalo yegranite eguquguqukayo,izinto ezisetyenziswayozingaveliswa ngobukhulu obufunekayo; ziqinile kwaye zihlala ixesha elide.

Iingenelo zeePlati zeGranite Surface

Ukubaluleka kokulinganisa kumphezulu olinganayo kwasekwa ngumqambi waseBritane uHenry Maudsley ngeminyaka yoo-1800. Njengomvelisi wezixhobo zoomatshini, wagqiba kwelokuba ukuveliswa rhoqo kwamacandelo kufuna umphezulu oqinileyo ukuze kulinganiswe ngokuthembekileyo.

Uguquko lwemizi-mveliso lwadala imfuno yokulinganisa umphezulu, ngoko ke inkampani yobunjineli iCrown Windley yadala imigangatho yokuvelisa. Imigangatho yeepleyiti zomphezulu yaqala ukubekwa yiCrown ngo-1904 kusetyenziswa isinyithi. Njengoko imfuno kunye neendleko zesinyithi zanda, kwaphandwa ngezinye izixhobo zokulinganisa umphezulu.

EMelika, umenzi wesikhumbuzo uWallace Herman wafumanisa ukuba i-granite emnyama yayiyeyona nto ilungileyo esetyenziselwa izinto zepleyiti yomphezulu endaweni yesinyithi. Njengoko i-granite ingenamagnethi kwaye ayigqwali, kungekudala yaba yindawo ekhethwayo yokulinganisa.

Ipleyiti yomphezulu wegranite lutyalo-mali olubalulekileyo kwiilebhu nakwizixhobo zovavanyo. Ipleyiti yomphezulu wegranite engama-600 x 600 mm ingafakelwa kwisitendi sokuxhasa. Izitendi zibonelela ngobude bokusebenza obuyi-34” (0.86m) kunye neendawo ezintlanu ezihlengahlengiswayo zokulinganisa.

Ukuze ufumane iziphumo zokulinganisa ezithembekileyo nezihambelanayo, ipleyiti yomphezulu wegranite ibalulekile. Njengoko umphezulu uthambile kwaye uzinzile, ivumela izixhobo ukuba zilawulwe ngononophelo.

Iingenelo eziphambili zeepleyiti zomphezulu wegranite zezi:

• Ayibonisi mbonakalo

• Ayimelani neekhemikhali kunye nokugqwala

• I-coefficient ephantsi yokwandiswa xa ithelekiswa nentsimbi yenqwelo ngoko ke ayichaphazeleki kangako kutshintsho lobushushu

• Iqinile ngokwendalo kwaye inzima

• Umgca womphezulu awuchaphazeleki ukuba ukrwelwe

• Ayiyi kugqwala

• Ayisebenzisi magnethi

• Kulula ukuyicoca nokuyigcina ikwimeko entle

• Ukulinganisa nokulungisa umphezulu kungenziwa kwindawo

• Ifanelekile ukugrumba kwiindawo zokufaka inxaso ezinemisonto

• Ukudambisa ukungcangcazela okuphezulu

Kwiivenkile ezininzi, amagumbi okuhlola kunye neelebhu, iipleyiti zomphezulu wegranite ezichanekileyo zixhomekeke kuzo njengesiseko sokulinganisa ngokuchanekileyo. Ngenxa yokuba umlinganiselo ngamnye othe tye uxhomekeke kumphezulu ochanekileyo wereferensi apho kuthathwa khona imilinganiselo yokugqibela, iipleyiti zomphezulu zibonelela ngeyona ndawo ifanelekileyo yokujonga umsebenzi kunye noyilo ngaphambi kokwenziwa kwemishini. Zikwasisiseko esifanelekileyo sokwenza imilinganiselo yobude kunye nokulinganisa umphezulu. Ngaphezu koko, umgangatho ophezulu wokuthe tyaba, ukuzinza, umgangatho ngokubanzi kunye nomsebenzi osebenzayo kuzenza zibe lukhetho olufanelekileyo lokufaka iinkqubo zokulinganisa ezintsonkothileyo zoomatshini, ze-elektroniki kunye nezokukhanya. Kuzo naziphi na ezi nkqubo zokulinganisa, kubalulekile ukugcina iipleyiti zomphezulu zilinganisiwe.

Phinda imilinganiselo kunye ne-Flatness

Zombini izilinganiso zokuthe tyaba kunye neziphindaphindwayo zibalulekile ukuqinisekisa umphezulu ochanekileyo. Ukuthe tyaba kungathathwa njengeendawo zonke ezikumphezulu eziqulethwe kwiiplani ezimbini ezihambelanayo, iplani esisiseko kunye neplani yophahla. Ukulinganiswa komgama phakathi kweplani kukuthe tyaba ngokubanzi komphezulu. Olu vavanyo lokuthe tyaba ludla ngokuba nokunyamezela kwaye lunokubandakanya uphawu lwebanga.

Ukunyamezelana kwe-flatness kwamabakala amathathu asemgangathweni kuchazwa kwinkcazo karhulumente njengoko kumiselwe yile fomyula ilandelayo:

Ibanga leLebhu AA = (40 + i-diagonal² / 25) x 0.000001 intshi (ecaleni elinye)

Ibanga lokuhlola A = Ibanga lelebhu AA x 2

Igumbi leZixhobo Ibanga B = Ibanga leLebhu AA x 4

Ukongeza ekuthe tyaba, ukuphinda-phinda kufuneka kuqinisekiswe. Ukulinganisa okuphindaphindiweyo kukulinganisa iindawo ezithe tyaba zasekuhlaleni. Lumlinganiselo othathwa naphi na kumphezulu wepleyiti oya kuphinda-phinda ngaphakathi kokunyamezelana okuchaziweyo. Ukulawula ukuthe tyaba kwendawo yasekuhlaleni ukuya ekunyamezeleni okuqinileyo kunokugqithisa ngokubanzi kuqinisekisa utshintsho oluncinci kwiprofayili yokuthe tyaba yomphezulu, ngaloo ndlela kunciphisa iimpazamo zasekuhlaleni.

Ukuqinisekisa ukuba ipleyiti yomphezulu ihlangabezana neemfuno ezithe tyaba kunye nemilinganiselo ephindaphindwayo, abavelisi beepleyiti zomphezulu wegranite kufuneka basebenzise i-Federal Specification GGG-P-463c njengesiseko seenkcazo zabo. Lo mgangatho ujongana nokuchaneka kokulinganisa okuphindaphindwayo, iipropati zezinto zegranite zepleyiti yomphezulu, ukugqitywa komphezulu, indawo yenkxaso, ukuqina, iindlela ezamkelekileyo zokuhlola kunye nokufakela izinto ezifakwe ngemisonto.

Ngaphambi kokuba ipleyiti yomphezulu iguge ngaphaya kwemilinganiselo yokuba ithambile iyonke, iya kubonisa izithuba ezigugileyo okanye ezigobileyo. Ukuhlolwa kwenyanga nganye kweempazamo zokulinganisa eziphindaphindwayo kusetyenziswa i-repeat reading gage kuya kuchonga amabala okuguga. I-repeat reading gage sisixhobo esichanekileyo esibona iimpazamo zasekuhlaleni kwaye sinokuboniswa kwi-high magnification electronic amplifier.

Ukujonga Ukuchaneka Kwepleyiti

Ngokulandela izikhokelo ezimbalwa ezilula, utyalo-mali kwipleyiti yomphezulu wegranite lufanele luhlale iminyaka emininzi. Ngokuxhomekeke ekusetyenzisweni kwepleyiti, indawo yevenkile kunye nokuchaneka okufunekayo, amaxesha okujonga ukuchaneka kwepleyiti yomphezulu ayahluka. Umgaqo oqhelekileyo kukuba ipleyiti entsha ifumane uhlengahlengiso olupheleleyo kungekapheli unyaka omnye emva kokuthengwa. Ukuba ipleyiti isetyenziswa rhoqo, kuyacetyiswa ukuba ifinyezwe eli xesha liye kwiinyanga ezintandathu.

Ngaphambi kokuba ipleyiti yomphezulu iguge ngaphaya kwemilinganiselo yokuba ithambile iyonke, iya kubonisa izithuba ezigugileyo okanye ezigobileyo. Ukuhlolwa kwenyanga nganye kweempazamo zokulinganisa eziphindaphindwayo kusetyenziswa i-repeat reading gage kuya kuchonga amabala okuguga. I-repeat reading gage sisixhobo esichanekileyo esibona iimpazamo zasekuhlaleni kwaye sinokuboniswa kwi-high magnification electronic amplifier.

Inkqubo yokuhlola esebenzayo kufuneka iquke ukujonga rhoqo nge-autocollimator, ebonelela ngokulinganisa ngokwenene ubunzulu be-flatness obunokulandelelwa yiNational Institute of Standards and Technology (NIST). Ukulinganisa okupheleleyo ngumvelisi okanye inkampani ezimeleyo kuyimfuneko ngamanye amaxesha.

Utshintsho Phakathi koLungiso

Kwezinye iimeko, kukho umahluko phakathi kokulinganiswa kwepleyiti yomphezulu. Ngamanye amaxesha izinto ezifana nokutshintsha komphezulu okubangelwa kukuguguleka, ukusetyenziswa gwenxa kwezixhobo zokuhlola okanye ukusetyenziswa kwezixhobo ezingalinganiswanga zinokubangela olu tshintsho. Nangona kunjalo, ezona zinto zimbini zixhaphakileyo bubushushu kunye nenkxaso.

Enye yezona zinto zibalulekileyo zizinto ezitshintshayo bubushushu. Umzekelo, umphezulu usenokuba uhlanjwe ngesicombululo esishushu okanye esibandayo ngaphambi kokulungiswa kwaye awuzange unikwe ixesha elaneleyo lokulungisa. Ezinye izizathu zokutshintsha kobushushu ziquka umoya obandayo okanye oshushu, ukukhanya kwelanga ngqo, ukukhanya okuphezulu okanye eminye imithombo yobushushu obukhanyayo kumphezulu wepleyiti.

Kunokubakho notshintsho kwi-gradient yobushushu obuthe nkqo phakathi kobusika nehlobo. Kwezinye iimeko, ipleyiti ayinikwa ixesha elaneleyo lokulungisa emva kokuthunyelwa. Kungumbono olungileyo ukurekhoda ubushushu be-gradient obuthe nkqo ngexesha lokwenziwa kovavanyo.

Esinye isizathu esiqhelekileyo sokwahluka komlinganiselo wokulinganisa yipleyiti engaxhaswanga kakuhle. Ipleyiti yomphezulu kufuneka ixhaswe kwiindawo ezintathu, okungcono ukuba ibekwe kwi-20% yobude ukusuka eziphelweni zepleyiti. Izixhasi ezibini kufuneka zibekwe kwi-20% yobubanzi ukusuka kumacala amade, kwaye inkxaso eseleyo mayibekwe embindini.