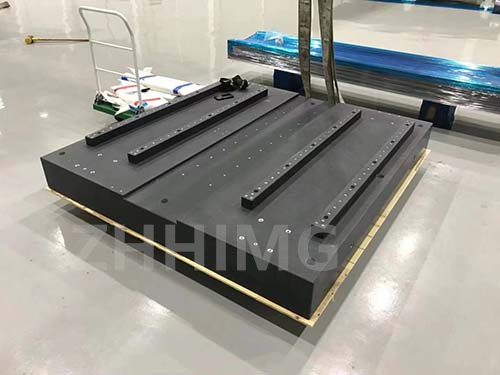

Kwimimandla ephambili efana nokuveliswa kwe-semiconductor, ukuhlolwa kwe-precision optical, kunye nokucutshungulwa kwezinto ze-nanomaterial, uzinzo kunye nokuchaneka kwezixhobo kumisela ngokuthe ngqo umgangatho wemveliso kunye nokusebenza kakuhle kwemveliso. Amaqonga okuchaneka kwe-granite, anokusebenza okuphindwe kathandathu kune-cast iron, aba yeyona athandwayo kushishino. Ngawaphi amaxabiso angenakutshintshwa asemva kwesi sibonelelo sokusebenza? Masihlole kunye iingenelo eziphambili zokukhetha amaqonga okuchaneka kwe-granite.

1. Isiqinisekiso sokugqibela sokuchaneka, iimpazamo ezincinci aziseyingxaki

Ngexesha lokwenziwa kwe-nanoscale, naluphi na ungcangcazelo oluncinci lunokukhokelela ekukhuculweni kwemveliso. Xa isiseko sesinyithi esityhidiweyo sijongene nongcangcazelo olubangelwa kukusebenza kwezixhobo okanye ukuphazamiseka kwendalo yangaphandle, ngenxa yokusebenza kwayo okungonelanga kodamping, amandla okungcangcazela kunzima ukuwachitha ngokukhawuleza, okubangela ukufuduka okanye ukushukuma kwezinto ezibalulekileyo zesixhobo. Iqonga lokuchaneka kwegranite, elineempawu zalo ezibalaseleyo zodamping, linokuguqula amandla okungcangcazela abe ngamandla obushushu okusasazwa ngephanyazo, licinezele ngempumelelo ukudluliselwa kunye nokwandiswa kongcamping.

Umzekelo, thabatha umatshini we-semiconductor photolithography. Emva kokusebenzisa iqonga lokuchaneka kwegranite, i-vibration amplitude yelensi yehlile ukusuka ku-±8μm ukuya ku-±1.3μm, nto leyo enciphisa impazamo yobubanzi bomgca we-chip pattern nge-75% kwaye iphucula kakhulu ukuchaneka kokwenziwa kwe-chip. Ekuhlolweni kokuchaneka kwe-optical, inokuqinisekisa ukuba ilensi yokubona yesixhobo sokuhlola ihlala izinzile, iphephe ukufiphala komfanekiso kunye nokuphambuka kwedatha okubangelwa kukungcangcazela, kwaye yenze neziphene ezincinci kwinqanaba le-0.1μm zingafihli ndawo.

Okwesibini, inobomi benkonzo obude kakhulu kwaye inciphisa iindleko zizonke

Phantsi kokungcangcazela kunye nefuthe elide nelihlala lihleli, isiseko sesinyithi esityhidiweyo sithambekele ekuqhekekeni okuncinci ngaphakathi, okukhokelela ekwehleni kwamandla olwakhiwo. Kufuneka itshintshwe emva kweminyaka emi-3 ukuya kwemi-5, oku kungagcini nje ngokunyusa ixesha lokungasebenzi kwezixhobo kodwa kuzisa neendleko eziphezulu zokugcinwa kunye nokutshintshwa. I-Granite yenziwe ngeekristale zeminerali ezifana ne-quartz kunye ne-feldspar, ezidityaniswe ngokusondeleyo ngeebhondi ze-ionic kunye ne-covalent. Inesakhiwo esixineneyo nesifanayo kwaye inokumelana nokudinwa okunamandla.

Nokuba emva kwamashumi amawaka emijikelo yokungcangcazela, iqonga lokuchaneka kwegranite lisenokugcina iipropati zomzimba nezikamatshini zizinzile, kwaye ubomi benkonzo yalo bunokuba ngaphezulu kwesithathu kunesiseko sesinyithi esityhidiweyo. Izibalo ezivela kwishishini elithile lokwenza izixhobo ezichanekileyo zibonisa ukuba emva kokusebenzisa amaqonga okuchaneka kwegranite, amaxesha okugcinwa kwezixhobo ehlile ngama-60%, kwaye umyinge weendleko zonyaka udlula isigidi seeyuan.

Isithathu. Ukulungelelana okugqwesileyo kokusingqongileyo, ukuphatha iimeko zokusebenza ezinzima ngokulula

Kwimeko yokwenyani yemveliso, izinto ezinje ngokutshintsha kobushushu, ukuphazamiseka kwe-electromagnetic, kunye nokubola kweekhemikhali zonke zinokuchaphazela ukusebenza kwezixhobo. Isiseko sesinyithi esityhidiweyo sinomlinganiselo ophezulu wokwanda kobushushu kwaye sithambekele kutshintsho lobukhulu phantsi kokuguquguquka kobushushu, nto leyo echaphazela ukuchaneka kwezixhobo. Okwangoku, sinokumelana nokubola okuphantsi kwaye sithambekele ekugqwaleni nasekuguquguqukeni phantsi kokukhukuliseka kwezinto zeekhemikhali.

Amaqonga okuchaneka kwegranite ane-coefficient ephantsi kakhulu yokwandiswa kobushushu (yi-1/20 kuphela yentsimbi ephoswe ngentsimbi), enokumelana ngempumelelo nempembelelo ebangelwa kukutshintsha kobushushu. Ineempawu zekhemikhali ezizinzileyo kwaye ayisabelani nezinto ezine-asidi okanye ze-alkaline, kwaye inokusebenza ngokuzinzileyo kwiindawo ezinzima ezifana neeworkshop ze-semiconductor kunye neelabhoratri zekhemikhali. Ukongeza, igranite ayiqhubi kwaye ayisebenzi ngemagnethi, kwaye ayichaphazeleki kukuphazamiseka kwe-electromagnetic, nto leyo eqinisekisa ngakumbi uzinzo lokusebenza kwezixhobo.

Okwesine, ukusebenza kweshishini kuqinisekisile ukuba kunceda ukhuphiswano lwamashishini ukuba luqhubele phambili

Iindlela zokusebenza zamashishini amaninzi aphambili kumashishini ahlukeneyo zibonise ngokupheleleyo ixabiso lamaqonga okuchaneka kwegranite. Emva kokuba umzi-mveliso omkhulu we-semiconductor wehlabathi uthathe indawo yeqonga lokuchaneka kwegranite, izinga lokuvelisa i-chip linyuke ukusuka kwi-78% ukuya kwi-92%, kwaye amandla okuvelisa anyuke nge-30%. Emva kokuba umenzi wezixhobo ze-optical eziphezulu ethathe eli qonga, ukuchaneka kokufumanisa iimveliso zakhe kwafikelela kwinqanaba eliphambili kushishino kwaye waphumelela ii-odolo ezininzi zamazwe ngamazwe.

Kukhuphiswano oluya lukhula ngamandla namhlanje kwimveliso echanekileyo, ukukhetha amaqonga okuchaneka kwegranite akukokuphucula nje ukusebenza kwezixhobo zemveliso, kodwa kukwasisigqibo esibalulekileyo samashishini sokuphucula umgangatho wemveliso, ukunciphisa iindleko kunye nokuphucula ukhuphiswano lwemarike. Ngokuqhubeka kweteknoloji, amaqonga okuchaneka kwegranite aya kudlala indima ebalulekileyo kwiinkalo ezininzi, ekhuthaza ishishini ukuba liphuhlise lifikelele ekuchanekeni okuphezulu kunye nokusebenza kakuhle okuphezulu.

Ixesha leposi: Meyi-14-2025