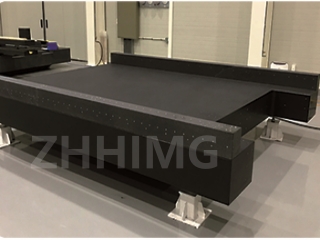

Kwicandelo lolawulo lokuhamba oluchanekileyo kakhulu, imodyuli yokuhamba echanekileyo kakhulu yokubhabha emoyeni ibe lukhetho olufanelekileyo kwiimeko ezininzi zokwenziwa kwemveliso ephezulu kunye nophando lwesayensi ngenxa yeempawu zayo zokushukuma ezingenakuphikiswa kunye nokuchaneka okuphezulu. Ukungeniswa kwesiseko sokuchaneka kwegranite kukufaka amandla aqinileyo ukuphucula ukusebenza kwayo, kodwa indibaniselwano yezi zimbini ayigqibelelanga.

Okokuqala, iingenelo ezibalulekileyo

Uzinzo olugqwesileyo: I-Granite emva kwezigidi zeminyaka yotshintsho lwejoloji, isakhiwo sangaphakathi sixinene kwaye siyafana, ikakhulu yi-quartz, i-feldspar kunye nezinye iiminerali ezidityaniswe ngokusondeleyo. Olu lwakhiwo lukhethekileyo lunika isiseko se-granite uzinzo olugqwesileyo. Xa kukho ukuphazamiseka kwangaphandle, njengokungcangcazela okubangelwa kukusebenza kwezixhobo ezinkulu ezijikelezileyo kunye nokuguquguquka kobushushu obungqongileyo, isiseko se-granite sinokuvimba kwaye sinciphise ngempumelelo. Kwiworkshop yokwenziwa kwee-chip ze-elektroniki, izixhobo zoomatshini kunye nezinye izixhobo zisebenza rhoqo, kwaye isiseko se-granite sinokunciphisa ubukhulu bokungcangcazela kwemodyuli yokuhamba echanekileyo kakhulu edluliselwa kwi-float yomoya ngaphezulu kwe-80%, ukuqinisekisa ukuhamba okugudileyo kwemodyuli, ukubonelela ngesiseko esizinzileyo seenkqubo ezichanekileyo kakhulu ezifana ne-lithography kunye nokukrola kwinkqubo yokwenziwa kwee-chip, kwaye kuphucula kakhulu imveliso yokwenziwa kwee-chip.

Ukugcinwa kokuchaneka okuphezulu kakhulu: Imodyuli yokunyakaza okuchanekileyo kakhulu kwe-air float ifuna ukuchaneka okuphezulu kakhulu, kwaye inzuzo ye-coefficient ephantsi yokwandiswa kwesiseko se-granite idlala indima ebalulekileyo koku. I-coefficient yokwandiswa kobushushu ye-granite ngokubanzi yi-5-7 × 10⁻⁶/℃, ephantsi kakhulu kunezixhobo zesinyithi eziqhelekileyo. Xa ubushushu butshintsha, ubungakanani besiseko buyatshintsha kancinci kakhulu. Kwicandelo le-astronomy, imodyuli yokunyakaza okuchanekileyo kakhulu ye-air float yokulungiswa kakuhle kwelensi yeteleskopu, enesiseko se-granite, inokuqinisekisa ukuba ukuchaneka kwendawo yelensi kugcinwa kwinqanaba le-sub-micron nokuba umahluko wobushushu phakathi kwemini nobusuku mkhulu, nto leyo enceda izazi ngeenkwenkwezi ukuba zibone ngokucacileyo izidalwa zasezulwini ezikude.

Ukumelana nokuguguleka okuhle kunye nobomi obude: Nangona imodyuli yokuhamba emoyeni ebhabhayo kakhulu inciphisa ukuguguleka ngokuthe ngqo ngexesha lokusebenza, kusekho umngcipheko othile wokuguguleka xa kusetyenziswa ixesha elide. Ubunzima begranite buphezulu, ubunzima beMohs bunokufikelela kwi-6-7, ukumelana nokuguguleka okunamandla. Kwilabhoratri yesayensi yezinto, imodyuli yokuhamba emoyeni ebhabhayo kakhulu esetyenziswa rhoqo, isiseko segranite sinokumelana ngempumelelo nokuguguleka kwesilayidi se-air float, xa kuthelekiswa nesiseko sesinyithi esiqhelekileyo, sinokwandisa umjikelo wokugcinwa kwemodyuli ngaphezulu kwe-50%, sinciphise iindleko zokugcinwa kwezixhobo, kwaye siqinisekise ukuqhubeka komsebenzi wophando lwesayensi.

Okwesibini, kukho iziphene

Ixabiso eliphezulu: Ixabiso lokufumana izinto eziluhlaza zegranite ezikumgangatho ophezulu liphezulu, kwaye ukwembiwa kwayo, ukuthuthwa kwayo kunye nokucubungula kwayo kuyinkimbinkimbi ngakumbi, kufuna izixhobo zobungcali kunye netekhnoloji. Ukusuka ekumbeni i-ore yegranite efanelekileyo ukuya ekucutshungulweni ukuya kwisiseko semodyuli yokuhamba emoyeni esichanekileyo kakhulu esihlangabezana neemfuno zokuchaneka okuphezulu, kubandakanya iinkqubo ezininzi ezintle, ezinje ngokusika ngokuchanekileyo, ukugaya, ukupolisha, njl.njl., okwenza iindleko zokuvelisa isiseko sokuchaneka kwegranite zinyuke kakhulu. Xa kuthelekiswa nezinye izinto ezifana nesinyithi, ixabiso linokuba ngaphezulu kaninzi okanye ngaphezulu, nto leyo ethintela ukusetyenziswa kwayo okukhulu ukuya kwinqanaba elithile, ingakumbi kumashishini amancinci okanye kumaziko ophando lwesayensi aneebhajethi ezincinci.

Ubunzima obunzima: Uxinano lwegranite lukhulu, malunga ne-2.6-3.1g /cm³, nto leyo ebangela isiseko esinzima sokuchaneka kwegranite. Kwinkqubo yokufakela nokuphatha izixhobo, kufuneka izixhobo zokuphakamisa zobungcali kunye nabasebenzi, nto leyo eyonyusa ubunzima beendleko zokufakela nezokuthutha. Kwezinye iimeko ezifuna ukuguquguquka okuphezulu koyilo lwendawo yezixhobo, isiseko esinzima sikwathintela ukushukuma okulula kunye nokufakwa kwakhona kwemodyuli yokuhamba echanekileyo kakhulu yeflothi yomoya, okuchaphazela ukusebenza kakuhle kunye nokuguquguquka kwezixhobo.

Kunzima ukuyicubungula: i-granite inobunzima obuphezulu kunye nokuqhekeka, kwaye izixhobo zokucubungula kunye neemfuno zenkqubo zingqongqo kakhulu. Kwinkqubo yokugaya, kulula ukuba neengceba, iingcangca kunye nezinye iziphene, kwaye kunzima ukuqinisekisa ukuchaneka kokugaya kunye nomgangatho womphezulu. Ukuze kufezekiswe ukuthe tye nokuthe tye okufunekayo kwimodyuli yokunyakaza echanekileyo kakhulu yeflothi yomoya, kufuneka uvavanyo oluninzi kunye nokulungiswa ngexesha lenkqubo yokucubungula, kwaye umjikelo wokucubungula ubude kwaye izinga lokwaliwa liphezulu, nto leyo enyusa ngakumbi iindleko zemveliso kunye neendleko zexesha.

Imodyuli yokunyakaza echanekileyo kakhulu enesiseko segranite esichanekileyo ineenzuzo ezibalaseleyo ekuzinzeni nasekuchanekeni, ezifanelekileyo kwiindawo eziphezulu ezineemfuno ezichanekileyo, kodwa ibhodi emfutshane efana neendleko, ubunzima kunye nobunzima bokucubungula nayo kufuneka iqwalaselwe ngokupheleleyo kwizicelo ezisebenzayo, kwaye ukhetho olufanelekileyo lwenziwa emva kokuvavanya iingenelo kunye nokungalungi.

Ixesha leposi: Epreli-08-2025