Iilathe ze-granite mechanical zifumene ingqwalasela enkulu kwishishini lokuvelisa ngenxa yokuzinza kwazo okuphezulu kunye nokuchaneka. Uhlalutyo lweeparameter zobugcisa zeelathe ze-granite mechanical lubalulekile ekuqondeni ukusebenza kwazo kunye nokufaneleka kwazo kwizicelo ezahlukeneyo zoomatshini.

Enye yeeparameter zobugcisa eziphambili ekufuneka ziqwalaselwe kukuqina kwesakhiwo segranite. Igranite, njengoko ililitye lendalo, inika ukuqina okugqwesileyo xa kuthelekiswa nezinto zemveli ezifana nentsimbi ephosiweyo okanye intsimbi. Oku kuqina kunciphisa ukungcangcazela ngexesha lokwenziwa, okukhokelela ekugqityweni komphezulu okuphuculweyo kunye nokuchaneka kobukhulu. Iimpawu zegranite ezisisiseko zikwanegalelo ekuzinzeni kobushushu, okubalulekileyo ekugcineni ukuchaneka kwiindawo ezinokuguquguquka kobushushu.

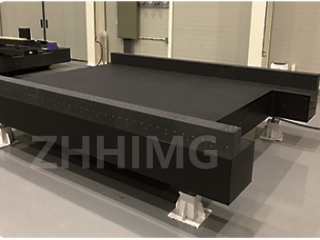

Enye iparameter ebalulekileyo bubunzima be-lathe yegranite. Ubunzima obukhulu be-lathe yegranite bubonelela ngesiseko esiqinileyo esinciphisa ngakumbi ukungcangcazela kwaye sonyusa uzinzo. Olu phawu luluncedo ngakumbi kwimisebenzi yoomatshini ekhawulezayo apho nokungcangcazela okuncinci kunokukhokelela kwiimpazamo ezinkulu.

Uyilo lwe-granite mechanical lathe nalo ludlala indima ebalulekileyo ekusebenzeni kwayo. Uyilo lomatshini, kubandakanya indawo ye-spindle kunye nezibambi zezixhobo, kufuneka luphuculwe ukuqinisekisa ukusika okusebenzayo kunye nokuncipha kokuguguleka kwezixhobo. Ukongeza, ukuhlanganiswa kweenkqubo zolawulo eziphambili kunye nesoftware kunokuphucula amandla okusebenza kwe-granite lathes, okuvumela imisebenzi enzima yoomatshini bokuchwetheza ngocoselelo oluphezulu.

Ngaphezu koko, ukugqitywa komphezulu wezinto zegranite yiparameter ebalulekileyo echaphazela ukusebenza ngokubanzi kwelathe. Umphezulu ocoliweyo kakuhle unciphisa ukungqubana kunye nokuguguleka, okufaka isandla ekuqhubekeni kwexesha elide komatshini kunye nomgangatho weemveliso ezigqityiweyo.

Ukuqukumbela, uhlalutyo lweeparameter zobugcisa bee-granite mechanical lathes lutyhila iingenelo zazo ngokubhekiselele kukuqina, uzinzo, kunye nokuchaneka. Njengoko amashishini eqhubeka nokufuna izisombululo zoomatshini abasebenza ngokuphezulu, ii-granite lathes zikulungele ukudlala indima ebalulekileyo ekuphuculeni ubuchwepheshe bokuvelisa.

Ixesha lokuthumela: Disemba-05-2024