.

Kule mihla yophuhliso olukhawulezayo lobuchwepheshe, izixhobo zokuhlola iiphaneli ze-8K zibalulekile ekuqinisekiseni umgangatho ophezulu wezikrini zokubonisa. Xa izixhobo ezinjalo zisebenza, zineemfuno eziphezulu kakhulu zokuzinza kwendawo yokubhaqa. Naluphi na ungcangcazelo oluncinci lunokubangela ukuphambuka kwiziphumo zobhaqo. I-granite, ngenxa yeempawu zayo ezizodwa zomzimba, iye yaba yinto efanelekileyo kwisicwangciso sokulwa nokungcangcazela kwezixhobo zokuhlola iiphaneli ze-8K.

Iingenelo ezikhethekileyo zegranite

I-granite iqinile ngokwendlela ebukeka ngayo kwaye inobulukhuni obuphezulu kakhulu. Ulwakhiwo lwayo lwangaphakathi luncinci, kwaye amandla okubopha phakathi kweekristale aqinile, anokumelana ngempumelelo nempembelelo kunye nokuguquguquka kwamandla angaphandle. Olu bulukhuni buphezulu lwenza i-granite ingabi nakwenzeka ukuba iguqulwe kakhulu xa ithwala ubunzima besixhobo kwaye ijongene nokungcangcazela okunokwenzeka, inika inkxaso yesiseko esizinzileyo kwizixhobo zokufumanisa.

Okwangoku, igranite ikwanazo neempawu ezintle zokudambisa. Ukudambisa kubhekisa kubuchule bento bokusebenzisa amandla nokunciphisa ubukhulu bokungcangcazela ngexesha lenkqubo yayo yokungcangcazela. Iimpawu zokudambisa zegranite zivela kwisakhiwo sayo esintsonkothileyo sezimbiwa zangaphakathi kunye neembobo ezincinci. Xa ukungcangcazela kudluliselwa kwigranite, ezi zakhiwo kunye neembobo zinokuguqula amandla okungcangcazela abe zezinye iintlobo zamandla ezifana namandla obushushu, ngaloo ndlela zinciphise ngokukhawuleza ukungcangcazela. Xa kuthelekiswa nezinye izinto, igranite inefuthe elibaluleke ngakumbi lokudambisa kwaye inokunciphisa kakhulu impembelelo yokungcangcazela kwangaphandle kwizixhobo zokufumanisa.

Iindlela zokusebenzisa i-granite kwiinkqubo zokulwa nokungcangcazela

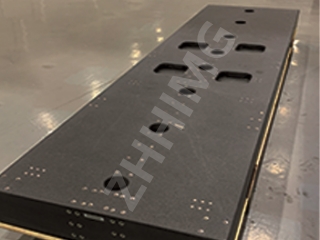

Njengesiseko sezixhobo

Ukwenza isiseko sezixhobo zokuhlola ngegranite yindlela eqhelekileyo yokuthintela ukungcangcazela. Ngokucwangciswa ngononophelo, umphezulu wesiseko segranite ufikelela kumgangatho ochanekileyo kakhulu, oqinisekisa ukuba izixhobo zinokubekwa ngokuzinzileyo emva kokufakwa. Ngenxa yegranite

Isiseko singahlula ngempumelelo ukungcangcazela okudluliswa emhlabeni, sinciphise ukuphazamiseka kokungcangcazela kwizinto ezichanekileyo ngaphakathi kwesixhobo, kwaye senze inkqubo yokufumanisa izinzile kwaye ithembeke ngakumbi. Umzekelo, kwezinye izixhobo zokuhlola iiphaneli ze-8K eziphezulu, ukusetyenziswa kweziseko zegranite ezinobukhulu obuziisentimitha ezininzi, kunye neendlela zokufakela ezichanekileyo, kunokunciphisa impembelelo yokungcangcazela komhlaba ukuya kwinqanaba elingaphantsi kakhulu, ngaloo ndlela kuqinisekiswa ukuchaneka nokuphindaphindwa kweziphumo zovavanyo.

Isetyenziswa kunye nezixhobo zokwahlukanisa ukungcangcazela

Ukuphucula ngakumbi isiphumo sokulwa nokungcangcazela, igranite idla ngokusebenza kunye nezinto ezahlukeneyo zokwahlukanisa ukungcangcazela. Ukufaka ii-raber vibration isolation pads phantsi kwesiseko segranite yindlela elula nesebenzayo. Irabha ineempawu ezithambileyo nezithambileyo, ezikwaziyo ukufunxa nokukhusela amandla okungcangcazela emhlabeni. Xa ukungcangcazela kudluliselwa kwi-raber vibration isolation pad, ukuguquguquka kwayo okuthambileyo kuguqula kancinci amandla okungcangcazela abe ngamandla obushushu ngaphakathi kwirabha. Okwangoku, isiphumo sokungcangcazela kwerabha sikwacinezela ukudluliselwa okuqhubekayo kokungcangcazela. Ngale ndlela, emva kokuqhawulwa kokuqala kokungcangcazela zii-raber vibration isolation pads, ukungcangcazela okuncinci okuseleyo kuncitshiswa ngakumbi yisiseko segranite, nto leyo ephucula kakhulu ukusebenza kwenkqubo yonke yokulwa nokungcangcazela.

Ukongeza, indibaniselwano yenkqubo yokwahlula i-air flotation vibration kunye ne-granite ikwasetyenziswa kakhulu kwezinye izixhobo zokufumanisa ezichanekileyo. Inkqubo yokwahlula i-air flotation vibration ihlukanisa i-vibration ngokwenza ifilimu yomoya enoxinzelelo oluphezulu phakathi kwesiseko se-granite nomhlaba, isebenzisa ithuba lokucinezeleka komoya. Isiseko se-granite, esixhaswa yinkqubo yokwahlula i-air, siphantse sibe kwimeko yokuxhonywa ngaphandle kokungqubana kwaye sinokuhlukanisa ngokufanelekileyo i-low-frequency vibration. Le ndlela yokudibanisa ifanelekile ngokukodwa kwinkqubo yokuhlola iphaneli ye-8K ebuthathaka kakhulu kwi-vibration, njengecandelo lokuhlola i-optical elichanekileyo kakhulu. Inokuqinisekisa ukuba izixhobo zokuhlola zisebenza kwindawo ezinzileyo kakhulu kwaye zifezekise ukuchongwa ngokuchanekileyo kweziphene ezincinci kwiphaneli.

Isishwankathelo seenzuzo zeenkqubo zegranite zokulwa nokungcangcazela

I-Granite ineengenelo ezininzi kwisicwangciso sokulwa nokungcangcazela sezixhobo zokuhlola iiphaneli ze-8K. Ngokwembono yokusebenzisa kakuhle iindleko, i-granite, njengezinto zendalo, inemithombo eyahlukeneyo kunye nexabiso elifanelekileyo. Xa kuthelekiswa nezinye izixhobo zokwenziwa eziphezulu okanye izixhobo ezintsonkothileyo zokulwa nokungcangcazela, ukusebenzisa i-granite ukwakha inkqubo yokulwa nokungcangcazela kunokulawula ngokufanelekileyo iindleko ngelixa kuqinisekiswa isiphumo sokulwa nokungcangcazela.

Ngokuphathelele ukuzinza nokuqina, ukuqina okuphezulu kunye nokuzinza okugqwesileyo ngokomzimba nangokweekhemikhali kwegranite kwenza ukuba ikwazi ukugcina ukusebenza okuzinzileyo ixesha elide. Ayichaphazeleki lula ziimeko zokusingqongileyo ezifana nobushushu kunye nokufuma ukuba ziguquguquke okanye zinciphise ukusebenza kwayo, kwaye inokubonelela ngesiqinisekiso sokulwa nokungcangcazela esihlala ixesha elide nesithembekileyo sezixhobo zokuchonga. Nokuba ngexesha lokusetyenziswa ixesha elide kunye nokuqina okuphezulu, inkqubo yokulwa nokungcangcazela yegranite isenokugcina ukusebenza okugqwesileyo kokulwa nokungcangcazela, ukunciphisa ukusilela kwezixhobo kunye nokugcinwa okubangelwa ziingxaki zokungcangcazela, kunye nokuphucula ubomi benkonzo iyonke kunye nokusebenza kakuhle kwezixhobo.

Ukuqukumbela, i-granite, eneempawu zayo ezizodwa, idlala indima engenakutshintshwa nebalulekileyo kwisicwangciso sokulwa nokungcangcazela kwezixhobo zokuhlola iiphaneli ze-8K, ibonelela ngesiseko esiqinileyo nesithembekileyo sokuqinisekisa ukusebenza ngokuchanekileyo kwezixhobo zokuhlola kunye neziphumo zovavanyo ezisemgangathweni ophezulu.

Ixesha leposi: Meyi-19-2025