### Ukusetyenziswa kweGranite Square Ruler kuMlinganiselo woBunjineli

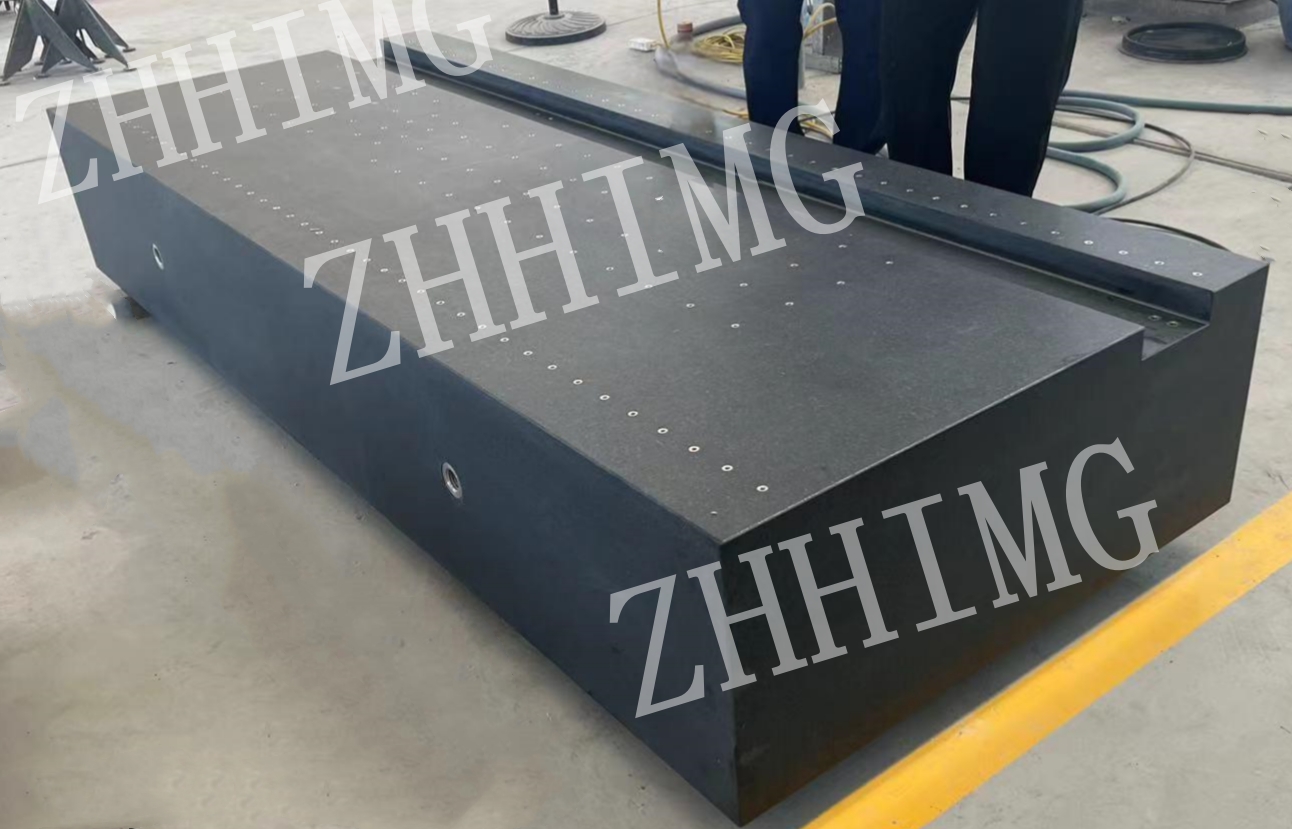

I-granite square ruler sisixhobo esibalulekileyo kwicandelo lokulinganisa ubunjineli, esaziwa ngokuchaneka kwayo nokuqina kwayo. Yenziwe nge-granite enoxinano oluphezulu, esi sixhobo senzelwe ukubonelela ngee-engile zasekunene ezichanekileyo kunye neendawo ezithe tyaba, nto leyo eyenza ukuba ibe yeyona ibalulekileyo kwizicelo ezahlukeneyo zobunjineli.

Enye yezona ndlela ziphambili zokusebenzisa i-granite square ruler kukulungelelanisa nokuseta oomatshini nezixhobo. Iinjineli zihlala ziyisebenzisa ukuqinisekisa ukuba izinto zibekwe ngokuchanekileyo, nto leyo ibalulekileyo ekusebenzeni nasekuhlaleni ixesha elide kweenkqubo zoomatshini. Ukuqina kwe-granite kuvumela ukwanda okuncinci kobushushu, ukuqinisekisa ukuba imilinganiselo ihlala ihambelana nakwiimeko ezahlukeneyo zendalo.

Ukongeza ekulungelelaniseni, i-granite square ruler isetyenziswa rhoqo kwiinkqubo zokulawula umgangatho. Ngexesha lesigaba sokuvelisa, iinjineli zisebenzisa esi sixhobo ukuqinisekisa ubungakanani beendawo kunye neendibano. Inqanaba eliphezulu lokuchaneka elibonelelwa yi-granite square ruler linceda ekuchongeni naluphi na ukuphambuka kwii-tolerances ezithile, ngaloo ndlela kuqinisekiswa ukuba iimveliso ziyahlangabezana nemigangatho yoshishino.

Ngaphezu koko, i-granite square ruler iluncedo kumsebenzi woyilo. Iinjineli kunye neengcali zoomatshini bayisebenzisa ukuphawula imigca echanekileyo kunye nee-engile kwizixhobo, okwenza kube lula ukusika nokubumba ngokuchanekileyo. Olu setyenziso lubaluleke kakhulu kumashishini afana neenqwelo-moya kunye neemoto, apho ukuchaneka kubaluleke kakhulu.

Enye inzuzo ebalulekileyo ye-granite square ruler kukuchasana kwayo nokuguguleka nokubola. Ngokungafaniyo ne-metal rulers, ezinokugoba okanye zonakale ngokuhamba kwexesha, i-granite igcina ukuthembeka kwayo, inika indawo ethembekileyo yokubhekisa iminyaka. Olu bude bexesha luyenza ibe lutyalo-mali olungabizi kakhulu kwiinkampani zobunjineli.

Ukuqukumbela, ukusetyenziswa kwe-granite square ruler ekulinganiseni ubunjineli kubanzi, kuquka ukulungelelaniswa, ulawulo lomgangatho, umsebenzi woyilo, kunye nokuqina. Ukuchaneka kwayo kunye nokuthembeka kwayo kuyenza ibe sisixhobo esibalulekileyo kwiinjineli ezilwela ukugqwesa kwiiprojekthi zazo.

Ixesha lokuthumela: Novemba-05-2024