Njengomvelisi ochwephesha wezixhobo zokulinganisa ngokuchanekileyo, i-ZHHIMG ibizinikele kwi-R&D, ukuveliswa kunye nokugcinwa kwezixhobo zoomatshini be-granite kangangeminyaka emininzi. Iimveliso zethu ziye zafumana udumo oluphezulu kubathengi kwihlabathi liphela, ingakumbi kwiindawo zovavanyo oluchanekileyo. Ukuba ufuna izixhobo zoomatshini be-granite ezinokuthenjwa, eli nqaku liza kukunceda uqonde ububanzi besicelo sazo, iingenelo zobugcisa kunye neenkonzo zokwenza ngokwezifiso.

1. IiNdawo eziBanzi zoSetyenziso lweeGranite Mechanical Components

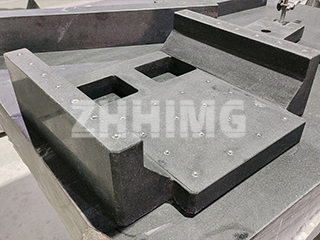

Izixhobo ze-granite mechanical zizixhobo ezibalulekileyo zokulinganisa ngokuchanekileyo, ezisetyenziswa kakhulu kwiimeko ezahlukeneyo zovavanyo nokuhlolwa. Iimpawu zazo zezinto ezibonakalayo ezikhethekileyo kunye noyilo olunokwenziwa ngokwezifiso zizenza zifaneleke kumashishini amaninzi:

- Ishishini le-Elektroniki: Lisetyenziswa ekuvavanyweni ngokuchanekileyo kwezixhobo ze-elektroniki, ukuqinisekisa ukuchaneka kokuhlanganiswa kwezixhobo ezincinci.

- Ubunjineli boomatshini: Buthatha indawo yeepleyiti zesinyithi zemveli ngokongeza imingxunya (ngemingxunya, imingxunya enemisonto) kunye nemingxunya (ii-T - ii-slots, u-U - ii-slots) kumphezulu, zilungele ukuhlolwa kweendawo zoomatshini kunye nokubekwa kwindawo yokuhlanganisa.

- Ishishini Elilula Nemveliso: Isetyenziswa ekulinganiseni ubungakanani bemveliso, ulawulo lomgangatho kunye novavanyo lomgca wemveliso, ukuphucula ukusebenza kakuhle kwemveliso kunye nomgangatho wemveliso.

- Amaziko eLebhu kunye noPhando: Alungele uvavanyo lwelebhu kunye neeprojekthi zovavanyo oluchanekileyo. Iilebhu ezininzi ezaziwayo zikhetha iimveliso zethu ngenxa yokusebenza kwazo okuzinzileyo kunye nokuchaneka okuphezulu.

2. Amabanga okuChaneka kunye neemfuno zokusingqongileyo

Ngokwemigangatho yesizwe saseTshayina, izinto zoomatshini zegranite zahlulwe zibe ziiklasi ezintathu zokuchaneka: Ibanga lesi-2, iBanga loku-1 kunye neBanga lesi-0. Iiklasi ezahlukeneyo zineendawo ezahlukeneyo zokusetyenziswa:

- Ibanga lesi-2 kunye neBanga loku-1: Ingasetyenziswa kwiindawo zobushushu eziqhelekileyo, ukuhlangabezana neemfuno zovavanyo oluchanekileyo ngokubanzi.

- Ibanga 0: Ifuna indawo yokusebenzela yobushushu obungaguqukiyo (20 ± 2℃). Ngaphambi kokuvavanya, kufuneka ibekwe kwigumbi lobushushu obungaguqukiyo kangangeeyure ezingama-24 ukuqinisekisa ukuchaneka kokulinganisa.

Iqela lethu liza kucebisa umgangatho ochanekileyo ofanelekileyo ngokusekelwe kwiimeko zakho zesicelo kunye neemfuno zokuchaneka, ukuqinisekisa ukusebenza kakuhle kweemveliso.

3. Iimpawu zeMpahla eziBalaseleyo zeGranite Mechanical Components

Ilitye elisetyenziselwe izinto ze-granite ze-ZHHIMG likhutshwe kwiinxalenye zamatye amakhulu ezigidi zeminyaka yokuguga kwendalo, nto leyo enika imveliso uzinzo oluhle kakhulu. Xa ithelekiswa nezinye izinto, ineenzuzo ezicacileyo:

| Uhlobo lwezinto | Uluhlu loxinano | Iingenelo eziphambili |

|---|---|---|

| Izixhobo zeGranite zeZHHIMG | 2.9~3.1g/cm³ | Uxinano oluphezulu, imo ezinzileyo, akukho tshintsho oluchanekileyo ngenxa yomahluko wobushushu |

| I-Granite yoMhlobiso | 2.6~2.8g/cm³ | Uxinano oluphantsi, ikakhulu lokuhombisa, alufanelekanga kuvavanyo lokuchaneka |

| Ikhonkrithi | 2.4~2.5g/cm³ | Amandla aphantsi, kulula ukuwaguqula, awanakusetyenziselwa izixhobo ezichanekileyo |

4. Iiplatifomu zeGranite Air ezenziwe ngokwezifiso - ezidadayo

Ukongeza kwizinto eziqhelekileyo zegranite mechanical components, i-ZHHIMG ikwabonelela ngamaqonga egranite alungiselelwe wena asebenzisa umoya othambileyo, asetyenziswa kakhulu kwizixhobo zokulinganisa ezichanekileyo:

- Uyilo lweSakhiwo: Iqonga elinomoya ohambayo sisixhobo sokulinganisa i-gantry yenkululeko enamaqondo amabini. I-slider ehambayo ifakwe kwi-granite guide rail, kwaye i-slider ixhotyiswe ngee-bearings ezinomoya ohambayo.

- Isiqinisekiso Sokuchaneka: Igesi yoxinzelelo oluphezulu ihluzwa ngesihluzo somoya kwaye izinziswe ngevalvu yokunciphisa uxinzelelo oluchanekileyo, ukuqinisekisa ukusebenza ngaphandle kokungqubana kwesilayida kwireyili yesikhokelo.

- Iteknoloji Yokucubungula: Umphezulu weqonga legranite uyagaywa amaxesha amaninzi. Ngexesha lokucubungula, kusetyenziswa inqanaba le-elektroniki ukulinganisa nokugaywa okuphindaphindiweyo, nto leyo ephucula kakhulu ukugaywa. Umahluko wokugaywa phakathi kobushushu obungaguqukiyo kunye nobushushu obuqhelekileyo yi-3μm kuphela.

5. Kutheni Ukhetha iiZHHIMG Granite Mechanical Components?

- Amava Atyebileyo: Amashumi eminyaka yamava emveliso kumaqonga e-granite, uyilo oluvuthiweyo, iinkqubo zemveliso kunye nolondolozo.

- Umgangatho Ophezulu: Ukukhethwa kwezinto ezisemgangathweni kunye nokucubungula ngokuchanekileyo, ukuhlangabezana neemfuno zamacandelo ovavanyo oluchanekileyo.

- Inkonzo Yokwenza Ngokwezifiso: Ngokwemeko-bume yokusetyenziswa komthengi kunye neemfuno zokuchaneka, yenza ngokwezifiso ubungakanani, imingxunya kunye nemingxunya yeemveliso.

- Inkonzo Yehlabathi: Ukubonelela ngenkonzo yobuchwepheshe ngexesha elifanelekileyo emva kokuthengisa kunye nenkxaso yobugcisa kubathengi kwihlabathi liphela.

Ukuba ufuna ukwazi okungakumbi malunga nokusetyenziswa kwezinto ze-granite mechanical kwishishini lakho, okanye ufuna isisombululo esenziwe ngokwezifiso, nceda uzive ukhululekile ukunxibelelana nathi ukuze ufumane ikowuteshini. Iqela lethu leengcali liza kukuphendula zingadlulanga iiyure ezingama-24!

Ixesha leposi: Agasti-27-2025