Kwiiholo ezithuleyo zeelabhoratri zokulinganisa, amagumbi okucoca e-semiconductor, kunye neesuite ze-aerospace metrology, utshintsho oluthuleyo luyaqhubeka. Aluqhutywa yisoftware okanye ii-sensors zodwa—kodwa zizinto ezakha isiseko sokulinganisa ngokwazo. Ngaphambili kolu tshintsho kukho izixhobo zokulinganisa ze-ceramic eziphambili, kubandakanya i-ultra-stable ceramic air straight ruler kunye ne-exceptional rigid high precision silicon-carbide (Si-SiC) parallelepiped kunye ne-square. Ezi azizozixhobo nje kuphela; zivumela ixesha elitsha apho uzinzo, ukuphindaphindwa, kunye nokungathathi cala kobushushu kungaxoxiswana.

Kangangeminyaka engaphezu kwesiqingatha senkulungwane, i-black granite yayilawula i-precision metrology. Ukufuma kwayo kwendalo, ukwanda kwayo kobushushu obuphantsi, kunye nokuba tyaba okugqwesileyo kwenze ukuba ibe yinto esetyenziswa kakhulu kwiiplati zomphezulu, izikwere, kunye nemiphetho ethe tye. Sekunjalo, njengoko amashishini esiya kwi-sub-micron kunye ne-nanometer-tolerances—ingakumbi kwi-semiconductor lithography, i-space optics, kunye ne-quantum computing—ukunqongophala kwe-granite kuye kwabonakala ngakumbi. Inzima, isengozini yokuqhekeka kwi-micro-chipping phantsi koqhagamshelwano oluphindaphindiweyo, kwaye, nangona idumile, isabonisa ukuqhekeka okuncinci kwexesha elide phantsi komthwalo okanye ukuguquguquka kwendalo.

Ngena kwiiseramikhi ezicwangcisiweyo: azizizo izinto zodongwe ezibuthathaka zemihla ngemihla, kodwa zixinene, zifana, zizixhobo ezisebenza kakuhle ezenziwe phantsi kobushushu obugqithisileyo kunye noxinzelelo. Phakathi kwezi, iindidi ezimbini zibalaseleyo kwizicelo zemetrology: i-alumina ecocekileyo kakhulu (Al₂O₃) kunye ne-reac-bonded silicon carbide (Si-SiC). Nangona zombini zibonelela ngophuculo olukhulu kunezixhobo zemveli, zisebenza indima eyahlukileyo—kwaye xa zidibene, zimele umda ophambili wento enokwenzeka kwimetrology enobukhulu.

Umzekelo, cinga ngerula yomoya othe tye yeceramic. Yenzelwe ukusetyenziswa kwizigaba zomoya okanye ii-interferometers ze-optical, esi sixhobo sifuna ukuthe tye okuphantse kube ngokugqibeleleyo, ubunzima obuncinci, kunye nokungashukumi kobushushu.iirula zeseramikhi—zenziwe ngendlela yokuba zithe tyaba kwaye zithe tye ngaphakathi kwe-±0.5 µm ngaphezulu kwe-500 mm kwaye zicociwe zibe rhabaxa ngaphantsi kwe-Ra 0.02 µm—zibonelela kanye ngaloo nto. Uxinano lwazo oluphantsi (~3.6 g/cm³) lunciphisa i-inertia kwiinkqubo zokulinganisa eziguquguqukayo, ngelixa uhlobo lwazo olungenamagnethi, olungena-conductive lususa ukuphazamiseka kwiindawo ezinobukrelekrele ze-elektroniki okanye zemagnethi. Kwizixhobo zokuhlola i-wafer okanye useto lokulinganisa i-laser tracker, apho ne-micron yesaphetha inokujika iziphumo, i-ceramic air straight ruler inika isalathiso esizinzileyo, esingena-injini esihlala siyinyani kuzo zonke iinguqu zobushushu kunye nemijikelo yokusebenza.

Kodwa xa kufuneka ukuqina okuphezulu kunye nokuqhuba kobushushu—njengokulungelelaniswa kwesipili seteleskopu yesithuba okanye i-high-power laser cavity metrology—iinjineli zijika zibe zii-silicon-carbide (Si-SiC) parallelepiped kunye nee-square components ezichanekileyo kakhulu. I-Si-SiC iphakathi kwezinto eziqinileyo ezaziwayo, kunye ne-Young's modulus edlula i-400 GPa—ngaphezulu kokuphindwe kathathu kunentsimbi—kunye nokuqhuba kobushushu okukhuphisana ne-aluminium. Okubaluleke kakhulu, i-coefficient yayo yokwandisa ubushushu (CTE) inokwakhiwa ukuze ifane neyeeglasi ze-optical okanye ii-silicon wafers, okuvumela ukwanda komahluko okufutshane kwi-hybrid assemblies. Isikwere se-Si-SiC esisetyenziswa njengesalathiso esiphambili kwisixhobo se-lithography se-EUV asiyi kuhlala nje imo yaso—siya kuxhathisa ukugqwetheka okuvela ekufudumaleni okanye ekungcangcazelweni kwendawo.

Okwenza ezi mpumelelo zibe nokwenzeka ayikokwenziwa kwezinto kuphela, kodwa bubuchule bokwenziwa kwezixhobo zokulinganisa zeseramikhi. Umatshini wokulungisa ngokuchanekileyo weSi-SiC, umzekelo, ufuna amavili okugaya idayimani, amaqonga e-CNC angaphantsi kwe-micron, kunye neenkqubo zokuleqa ezinamanqanaba amaninzi ezenziwa kwiindawo ezilawulwa bubushushu. Nokuba uxinzelelo oluncinci olushiyekileyo oluvela ekutshiseni okungafanelekanga lunokukhokelela ekuqhekekeni kwe-post-machining. Yiyo loo nto kuphela abavelisi abambalwa abakhethiweyo behlabathi abadibanisa ukuhlanganiswa kwezinto, ukwenziwa ngokuchanekileyo, kunye ne-metrology yokugqibela phantsi kophahla olunye—ubuchule obahlula abavelisi bokwenyani be-metrology kubaboneleli beseramikhi ngokubanzi.

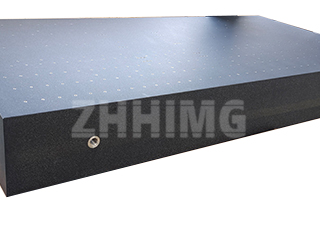

Kwi-ZHONGHUI INTELLIGENT MANUFACTURING (JINAN) GROUP CO., LTD (ZHHIMG), olu manyano oluthe nkqo lubalulekile kumsebenzi wethu. Izixhobo zethu zokulinganisa ze-ceramic—kuquka iimodeli ze-ceramic air straight ruler eziqinisekiswe yi-DIN 874 Grade AA kunye ne-high precision silicon-carbide (Si-Si-C) parallelepiped kunye ne-square artifacts ezinokulandelelwa ngokwemigangatho ye-PTB kunye ne-NIST—ziveliswa kwiindawo zokucoca ze-ISO Class 7 kusetyenziswa iiprotokholi zokucoca kunye nokugqiba. Yonke into idlula kuvavanyo olupheleleyo lwe-interferometric, ukuqinisekiswa kwe-CMM kokunyamezelana kwejometri (ukuthamba, ukufana, ukuthe nkqo), kunye novavanyo lokuthembeka komphezulu ngaphambi kokuthunyelwa. Isiphumo sisixhobo se-reference-grade esingahlangabezani nje nemigangatho—siyazidlula rhoqo kwiibhetshi.

Imfuno yokusebenza okunjalo iyakhula. Kwimveliso ye-semiconductor, i-EUV kunye neenkqubo ze-lithography eziphezulu ze-NA zifuna izakhiwo zokulungelelanisa ezizinzileyo ukuya kuthi ga kwi-nanometers ezilishumi ngaphezulu komgama wemitha-isikali—akunakwenzeka ngaphandle kwe-synergy ye-thermal-mechanical ye-Si-SiC. Kwi-aerospace, iibhentshi ze-satellite optical ezenziwe ngeereferensi ze-ceramic ziqinisekisa uzinzo kwi-orbit nangona ukujikeleza kobushushu okugqithisileyo. Kwanakwimimandla emitsha efana nokuchongwa kwamaza adonsela phantsi okanye uphuhliso lwewotshi ye-atomic, apho uzinzo lwe-picometer-level lubalulekile, izinto ze-ceramic kunye ne-Si-SiC metrology ziyaba yinto engabalulekanga.

Okubalulekileyo kukuba, ezi zixhobo zikwajongana nokuzinza kunye neendleko zizonke zobunini. Nangona utyalo-mali lokuqala kwi-silicon-carbide parallelepiped echanekileyo kakhulu lunokudlula olo lwe-granite equivalent, ubomi bayo benkonzo bunokuba bude ngokuphindwe ka-5-10 kwiindawo ezisetyenziswa kakhulu. Ayifuni ioyile, imelana nazo zonke izinyibilikisi eziqhelekileyo kunye neeplasma, kwaye ayifuni ukuhlaziywa kwakhona ngenxa yokufunxwa komswakama—ngokungafaniyo nentsimbi ephosiweyo okanye ezinye iigranite. Kubaphathi bomgangatho abasebenza phantsi kwe-AS9100, i-ISO 13485, okanye imigangatho ye-SEMI, oku kuthembeka kuthetha ngokuthe ngqo ukuba ixesha lokungasebenzi linciphile, iziphumo ezimbalwa zophicotho-zincwadi, kunye nokuzithemba okukhulu kwabathengi.

Ngaphezu koko, ubuhle kunye nokusebenza kakuhle kwezi zixhobo akufuneki kujongwe. Isikwere se-Si-SiC esicwebezelayo sikhazimla ngentsimbi kodwa sinobunzima obungaphantsi kwentsimbi. Irula yomoya othe tye yeceramic ivakala iqinile kodwa iphakama ngokulula—ilungele ukuqinisekiswa ngesandla kwiindawo ezixineneyo. Ezi mpawu zigxile ebantwini zibalulekile kwiilabhoratri zehlabathi lokwenyani apho i-ergonomics kunye nokulula kokusetyenziswa zichaphazela ukuhamba komsebenzi wemihla ngemihla.

Ngoko ke, ngaba izixhobo zokulinganisa zeseramikhi zichaza ngokutsha ukuchaneka okuphezulu kakhulu? Impendulo ikulwazi—nakuluhlu olukhulayo lweenkokheli zehlabathi ezizichaza njengezisemgangathweni. Ukususela kumaziko esizwe e-metrology aqinisekisa imigangatho yobude besizukulwana esilandelayo ukuya kubaboneleli beTier 1 abaqinisekisa izinto ze-EV drivetrain, utshintsho lucacile: xa ukungaqiniseki kufuneka kuncitshiswe, iinjineli ziyazithemba iiseramikhi ezilungisiweyo.

Njengoko amashishini eqhubeka nohambo lwawo olungapheliyo oluya kulawulo lwesikali seathom, inyaniso enye ayiphikiswa: ikamva lokulinganisa aliyi kuqoshwa ngamatye okanye lifakwe kwisinyithi. Liya kutshiswa, licolwe, lize licolwe ngeseramikhi—kunye nesilicon carbide.

I-ZHHIMG INTELLIGENT MANUFACTURING (JINAN) GROUP CO., LTD (ZHHIMG) ngumvelisi owaziwayo kwihlabathi liphela kwizisombululo ze-metrology ze-ceramic kunye ne-silicon-carbide ezichanekileyo kakhulu. Igxile kwizixhobo zokulinganisa ze-ceramic, i-ceramic air straight ruler, kunye ne-high precision silicon-carbide (Si-SiC) parallelepiped kunye nezinto zesikwere, i-ZHHIMG inikezela ngezinto eziqinisekisiweyo ngokupheleleyo, ezikumgangatho welebhu ze-semiconductor, i-aerospace, ukhuselo, kunye nezicelo zophando lwesayensi. Ixhaswa yi-ISO 9001, i-ISO 14001, kunye ne-CE certifications, iimveliso zethu zithembeke ngamashishini aphambili etekhnoloji kwihlabathi liphela. Jonga ipotifoliyo yethu ye-metrology ephucukileyo aphawww.zhhimg.com.

Ixesha leposi: Disemba-05-2025