Kwihlabathi lanamhlanje lemveliso ephucukileyo, "izixhobo ze-3D" azisabhekiseli kuphela koomatshini bokulinganisa abadibeneyo. Eli gama ngoku liquka inkqubo ebanzi yendalo: ii-laser trackers, ii-structured-light scanners, ii-photogrammetry rigs, ii-multi-sensor metrology cells, kwaneenkqubo zombono eziqhutywa yi-AI ezisetyenziswa kuyo yonke into ukusuka kwi-aerospace assembly ukuya kwi-biomedical prototyping. Ezi zixhobo zithembisa isisombululo esingazange sibonwe ngaphambili, isantya, kunye nokuzisebenzela ngokuzenzekelayo—kodwa ukusebenza kwazo kuthembeke kuphela njengomphezulu ezimi kuwo. Kwi-ZHHIMG, sibone izixhobo ezininzi ze-3D eziphezulu zingasebenzi kakuhle kungengenxa ye-optics okanye isoftware ephosakeleyo, kodwa ngenxa yokuba zifakwe kwiziseko ezingenakukwazi ukuhlangabezana neemfuno ze-metrology echanekileyo.

Isisombululo asikokulinganisa ngakumbi—yifiziksi engcono. Kwaye kangangeminyaka engaphezu kwamashumi amabini, loo fiziksi ibisoloko ikhomba kwisixhobo esinye: igranite. Ayisiyonto yokukhumbula izinto zakudala, kodwa njengesiseko esifanelekileyo ngokwesayensi kuyo nayiphi na inkqubo apho iimicrons zibalulekileyo khona. Nokuba uskena iblade yeturbine enesithuba samanqaku esingaphantsi kwe-10µm okanye ulungelelanisa iingalo zerobhothi kwindlela yokusebenza yedijithali ezimbini, ukuzinza kwesiseko sakho somatshini wegranite kwizixhobo ze-3D kumisela ngokuthe ngqo ukuthembeka kwedatha yakho.

Iingenelo zeGranite zisekelwe kwiimpawu zomzimba ezingaguqukiyo. I-coefficient yayo yokwanda kobushushu—ngesiqhelo phakathi kwe-7 kunye ne-9 × 10⁻⁶ nge °C—iphakathi kwezona zinto ziphantsi kakhulu kuzo naziphi na izinto zobunjineli ezifumanekayo. Ngokwendlela esebenzayo, oku kuthetha ukuba i-granite slab ye-2-meter iya kwanda okanye inciphe ngaphantsi kwe-2 microns kubushushu obuqhelekileyo befektri obuyi-5°C. Thelekisa oko nentsimbi (≈12 µm) okanye i-aluminium (≈60 µm), kwaye umahluko uba mkhulu. Kwizixhobo ze-3D ezixhomekeke kwireferensi yendawo epheleleyo—njengezixhobo zokulandelela i-laser ezisetyenziswa ekulungelelaniseni amaphiko eenqwelo-moya—le ndlela yokungathathi cala kobushushu ayisiyonto yokuzikhethela; ibalulekile.

Kodwa ukuzinza kobushushu kuyinxalenye yesiqingatha sebali. Enye into ebalulekileyo kukudambisa ukungcangcazela. Iifektri zanamhlanje ziyindawo enengxolo: ii-spindles ze-CNC zijikeleza kwi-20,000 RPM, iirobhothi zingena kwiindawo zokumisa, kwaye iinkqubo ze-HVAC zityhala umgangatho. Ezi ngcangcazela, ezihlala zingabonwa ngabantu, zinokufiphalisa ii-optical scans, zisebenzise amacebiso e-jitter probe, okanye zisuse ii-arrays ze-multi-sensor. I-Granite, enesakhiwo sayo esixineneyo se-crystalline, ifunxa kwaye ichithe ezi ntshukumo ziphezulu kakhulu ngempumelelo kuneefreyimu zesinyithi okanye iitafile ezidityanisiweyo. Uvavanyo oluzimeleyo lwelebhu lubonise ukuba iziseko ze-granite zinciphisa ukwandiswa kwe-resonant ukuya kuthi ga kwi-65% xa kuthelekiswa ne-cast iron - umahluko oguqulela ngqo kumafu acocekileyo kunye nokuphindaphinda okuqinileyo.

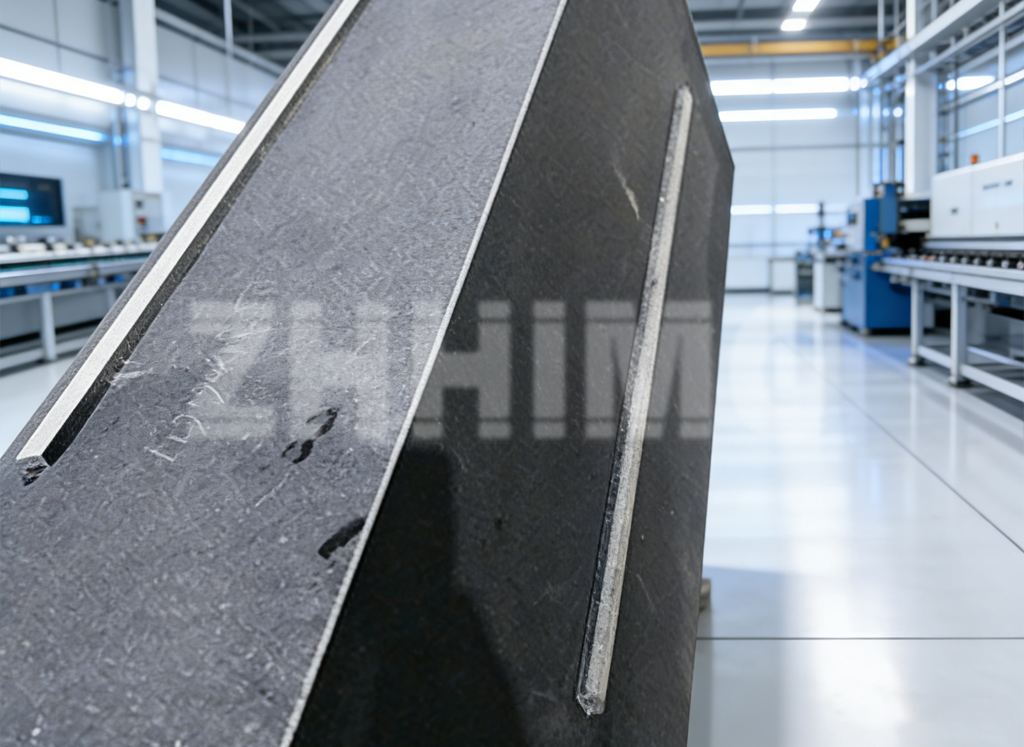

Apha eZHHIMG, asiyiphathi igranite njengempahla ethengiswayo.ibhedi yomatshini wegraniteKwizixhobo ze-3D esizenzayo siqala ngeebhloko eziluhlaza ezikhethiweyo ngokungqongqo—ngokuqhelekileyo i-diabase emnyama ecolekileyo okanye i-gabbro evela kwiindawo zokumba eziqinisekisiweyo zaseYurophu naseMntla Melika ezaziwa ngokuba ne-porosity ephantsi kunye noxinano oluhambelanayo. Ezi bhloko zidlula kwiinyanga ezili-12 ukuya kwezingama-24 zokwaluphala kwendalo ukuze zinciphise uxinzelelo lwangaphakathi ngaphambi kokuba zingene kwiholo yethu ye-metrology elawulwa yimozulu. Apho, iingcali ezingoochwephesha zijongana ngezandla ukuya kumlinganiselo wokuthamba ngaphakathi kwe-2-3 microns ngaphezulu kwe-span edlula iimitha ezi-3, emva koko zidibanise i-inserts ezinemisonto, ii-grounding lugs, kunye nee-modular fixturing rails zisebenzisa iindlela ezigcina ukuqina kwesakhiwo.

Olu qwalaselo kwiinkcukacha ludlulela ngaphaya kwesiseko ngokwaso. Ngokuya kusanda, abathengi bafuna okungaphezulu nje komphezulu othe tyaba—bafuna izakhiwo zenkxaso ezidibeneyo ezigcina ukuhambelana kwemetrological kuyo yonke ifreyimu yesixhobo. Yiyo loo nto siye saba ngoovulindlela ekusebenziseniizixhobo zoomatshini zegranitekwizixhobo ze-3D, kuquka ii-granite crossbeams, ii-granite probe nests, ii-granite encoder mounts, kwanee-granite-reinforced gantry columns. Ngokufaka i-granite kwiindawo eziphambili ezithwala umthwalo, sandisa uzinzo lobushushu kunye nokungcangcazela kwesiseko ukuya phezulu kwisakhiwo esishukumayo sesixhobo. Omnye umthengi wakutshanje kwicandelo lezixhobo ze-semiconductor utshintshe iingalo ze-carbon-fiber ngee-hybrid granite-composite linkages kwi-3D alignment rig yabo eyenziwe ngokwezifiso—kwaye wabona ukwehla komlinganiselo nge-58% kwi-shift yeeyure ezi-8.

Kakade ke, ayizizo zonke izicelo ezifuna ii-slabs ezipheleleyo ze-monolithic. Kwiisetingi eziphathekayo okanye ze-modular—ezifana nezikhululo ze-photogrammetry ezisetyenziswa ebaleni okanye ii-robot calibration cells ezihambayo—sinikezela ngeethayile ze-granite ezisemgangathweni kunye neepleyiti zesalathiso ezisebenza njengee-datam ezikwindawo ethile. Ezi granite zincinci ezichanekileyo zezinto ze-3D zinokufakwa kwiindawo zokusebenzela, kwi-robot pedestals, okanye nakwimigangatho yegumbi lokucoca, zibonelela ngendawo ye-anchor ezinzileyo naphi na apho kufuneka khona ireferensi yendawo ephezulu. Ithayile nganye iqinisekisiwe ngokwahlukeneyo ukuba ithambile, iyafana, kwaye igqitywe ngumphezulu, ukuqinisekisa ukulandeleka kwimigangatho ye-ISO 10360.

Kufanelekile ukujongana nengcamango ephosakeleyo eqhelekileyo: yokuba i-granite inzima, iyaphuka, okanye iphelelwe lixesha. Enyanisweni, iinkqubo zanamhlanje zokuphatha kunye nokufakela zenza amaqonga e-granite akhuseleke kwaye kube lula ukuwafaka kunangaphambili. Nangona i-granite ixinene, ukuqina kwayo akunakuthelekiswa nanto—ukufakelwa kwethu okudala, okususela kwiminyaka yoo-2000, kuhlala kusenzelwa imihla ngemihla ngaphandle kokonakala kokusebenza. Ngokungafaniyo nentsimbi epeyintiweyo etshiza okanye edibanisayo erhubuluzayo phantsi komthwalo, i-granite iyaphucuka ngokuhamba kwexesha, iphuhlisa umphezulu ogudileyo ngokusetyenziswa kancinci. Ayifuni kufakwa i-coating, ayidingi kugcinwa ngaphandle kokucoca rhoqo, kwaye ayidingi kulungiswa kwakhona ngenxa yokudinwa kwezinto.

Ngaphezu koko, uzinzo lubalulekile kule ndlela. I-granite yendalo ngokupheleleyo, ingasetyenziswa kwakhona, kwaye ifumaneka ngempembelelo encinci kwindalo xa imbiwa ngokusesikweni. Kwixesha apho abavelisi behlola umjikelo wobomi bempahla nganye, isiseko se-granite simele utyalo-mali lwexesha elide—kungekuphela nje ngokuchanekileyo, kodwa nakubunjineli obunoxanduva.

Siyazingca ngokubonakala ngokucacileyo. Iqonga ngalinye le-ZHHIMG liza nengxelo epheleleyo ye-metrology—kuquka iimaphu ze-flatness, ii-thermal drift curves, kunye neeprofayili zempendulo yokungcangcazela—ukuze iinjineli ziqinisekise ukufaneleka kwesicelo sazo esithile. Asixhomekeki kwiinkcukacha “eziqhelekileyo”; sipapasha idatha yovavanyo lokwenyani kuba siyazi ukuba kwi-precision metrology, ukuqikelela kubiza imali.

Olu qilima lusinike ubudlelwane neenkokheli kuzo zonke iindawo apho ukungaphumeleli kungeyondlela ifanelekileyo: ii-aerospace OEMs eziqinisekisa amacandelo e-fuselage, iifemu zezixhobo zonyango ezihlola iijometri zokufakelwa, kunye nabavelisi bebhetri ye-EV abadibanisa izixhobo ze-gigafactory. Omnye umthengisi weemoto waseJamani kutshanje udibanise izitishi ezintathu zokuhlola ezindala kwiseli enye ye-ZHHIMG-based multi-sensor cell enee-tactile probes kunye ne-blue-light 3D scanners—zonke zibhekisele kwi-granite datum efanayo. Isiphumo? Ulwalamano lomlinganiselo luphucukile ukusuka kwi-±12 µm ukuya kwi-±3.5 µm, kwaye ixesha lomjikelo lehle nge-45%.

Ngoko ke njengoko uvavanya ukusetyenziswa kwakho okulandelayo kwe-metrology, zibuze: ingaba ucwangciso lwakho lwangoku lwakhiwe kwisiseko esenzelwe inyaniso—okanye isivumelwano? Ukuba izixhobo zakho ze-3D zifuna uhlengahlengiso rhoqo, ukuba ukuphambuka kwakho kwi-scan-to-CAD kuyatshintshatshintsha ngendlela engalindelekanga, okanye ukuba uhlahlo lwabiwo-mali lwakho lokungaqiniseki luyaqhubeka nokwanda, ingxaki isenokungabi kwizixhobo zakho zokuvavanya, kodwa kwinto ezixhasayo.

Apha kwi-ZHHIMG, sikholelwa ukuba ukuchaneka kufanele kube yinto eqhelekileyo, kungabi yinto ehlawulelwayo. Ndwendwelawww.zhhimg.comukuphonononga indlela i-granite yethu echanekileyo yezixhobo ze-3D, kunye nezixhobo zoomatshini ze-granite ezakhiwe ngenjongo yezixhobo ze-3D, ezinceda ngayo iinjineli kwihlabathi liphela ukuguqula idatha yokulinganisa ibe yintembelo enokwenzeka. Kuba xa yonke i-micron ibala, akukho nto inokuthatha indawo yomhlaba oqinileyo.

Ixesha lokuthumela: Jan-05-2026