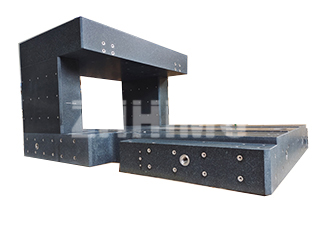

Xa kufikwa kwiipleyiti zomphezulu wegranite ezenziwe ngokwezifiso, abasebenzisi abaninzi bayabuza ukuba kunokwenzeka na ukongeza iimpawu zomphezulu eziqoshiweyo—ezifana nemigca yokulungelelanisa, iigridi, okanye iimpawu zesalathiso. Impendulo nguewe. Kwi-ZHHIMG®, asenzi nje kuphela iipleyiti zomphezulu wegranite ezichanekileyo, kodwa sikwabonelela ngezisombululo zomphezulu ezenziwe ngokwezifiso ukuphucula ukusetyenziswa kakuhle kwi-metrology kunye nokusetyenziswa kwe-assembly.

Kutheni kufuneka wongeze iimpawu zomphezulu?

Iimpawu zomphezulu ezifana nemigca yokulungelelanisa okanye iipateni zegridi zenza iipleyiti zomphezulu wegranite zibe nokuguquguquka ngakumbi:

-

Ukubeka kunye nokulungelelanisa - Imigca yokulungelelanisa inceda iinjineli ukuba zilungelelanise izinto zokusebenza kunye nezixhobo ngokukhawuleza.

-

Isalathiso soMlinganiselo – Iigridi okanye imigca enqamlezileyo isebenza njengezikhokelo ezibonakalayo zokuhlolwa kobukhulu.

-

Inkxaso yokuhlanganisa – Iimpawu ziphucula ukusebenza kakuhle kokuhlanganisa okanye ukulinganisa izixhobo.

Olu buchule longezelelekileyo luguqula ipleyiti yomphezulu wegranite ukusuka kwiplani yesalathiso esithe tyaba ibe sisixhobo sokuchaneka esisetyenziselwa iinjongo ezininzi.

Ukuchaneka kokukrola

Ingxaki eqhelekileyo kukuba ingaba ukukrola kuya kuyichaphazela na indlela ethe tyaba okanye ukuchaneka kwepleyiti yomphezulu wegranite. Kwi-ZHHIMG®, silandela izikhokelo ezingqongqo:

-

Ukukrola kwenziwa kuphela emva kokuba ipleyiti igutyiwe yaza yaxhunyelelwa kwindawo efunekayo.

-

Iimpawu azinzulu kwaye zicutshungulwa ngononophelo ukuze zingachaphazeli ukuchaneka komphezulu ngokubanzi.

-

Ukuchaneka kokukrola ngesiqhelo kunokufikelela kwi-±0.1mm, kuxhomekeke kubunzima bepateni kunye neemfuno zabathengi.

Oku kuqinisekisa ukuba iziphumo zokunyamezela ukuthamba kunye nokulinganiswa azitshintshi, ngelixa umsebenzisi ezuza kwiimpawu ezichanekileyo ezongezelelweyo.

Iinketho zokwenza ngokwezifiso

Abathengi banokucela uluhlu olubanzi lweemaki, kuquka:

-

Iigridi zokulungelelanisa (imigca ye-axis ye-XY)

-

Iindawo zokubhekisa kwiziko

-

Iimpawu ze-Crosshair zokulungelelanisa ukukhanya

-

Izikali okanye iirula ezenziwe ngokwezifiso eziqoshwe ngqo kwipleyiti

Iimpawu zingazaliswa ngombala owahlukileyo (njengomhlophe okanye otyheli) ukuze kubonakale ngcono ngaphandle kokuchaphazela ukuchaneka.

Usetyenziso lweePlates zeGranite Surface eziGrivwe

Iipleyiti zomphezulu wegranite ezineempawu eziqoshiweyo zisetyenziswa kakhulu kwezi:

-

Iilebhu zeMetrology zokulinganisa nokuhlola

-

Ukuhlanganiswa kwezixhobo ze-Optical ukuze kubekwe ngokuchanekileyo indawo

-

Iiworkshops zokulungisa ngokuchanekileyo ukuze kulungelelaniswe iinxalenye

-

Amashishini e-semiconductor kunye ne-elektroniki apho kufuneka khona useto oluchanekileyo kakhulu

Ngokudibanisa ukunyamezelana okuphezulu kokuthe tyaba kunye neegridi zokujonga ezibonakalayo, abasebenzisi bafumana ukusebenza kakuhle kunye nokuchaneka okukhulu kwimisebenzi yemihla ngemihla.

Kutheni Ukhetha i-ZHHIMG®?

I-ZHHIMG® iyaziwa kwihlabathi liphela ngezisombululo zegranite ezichanekileyo ezenziwe ngokwezifiso. Ngolwazi lwamashumi eminyaka, iinkqubo zokukrola ze-CNC eziphambili, kunye neengcali ezinobuchule, siyaqinisekisa:

-

Ubume bomphezulu obulingana ne-nanometer ngaphambi kokukrola

-

Ukuchwela ngokuchanekileyo ukuya kuthi ga kwi-± 0.1mm

-

Ukuthobela imigangatho yamazwe ngamazwe (i-DIN, i-JIS, i-ASME, i-GB)

-

Izatifikethi zokulinganisa ezilandelelwa kumaziko esizwe e-metrology

Oku kwenza i-ZHHIMG® ibe liqabane elithembekileyo kumashishini akumgangatho wehlabathi, ukusuka kubavelisi be-semiconductor ukuya kumaziko ophando.

Isiphelo

Ewe, kunokwenzeka ukucela imigca eqingqiweyo okanye iimpawu zegridi kwiipleyiti zomphezulu wegranite ezenziwe ngokwezifiso. Ngobuchwepheshe bokukrola obuphambili kunye nolawulo oluqinileyo lomgangatho, i-ZHHIMG® iqinisekisa ukuba iimpawu ezichanekileyo ziphucula ukusetyenziswa ngaphandle kokuphazamisa ukuchaneka. Kubathengi abafuna zombini ukuthe tyaba kunye nokusebenza, ipleyiti yomphezulu wegranite eneempawu eziqingqiweyo sisisombululo esifanelekileyo.

Ixesha leposi: Sep-26-2025