Kwimizi-mveliso ye-semiconductor kunye neye-display, izixhobo zokuhlola uluhlu zidlala indima ebalulekileyo ekuqinisekiseni umgangatho wemveliso. Ukusebenza kakuhle kwezi matshini kunokuphuculwa kakhulu kukukhethwa kwezinto ezisisiseko somatshini, kwaye i-granite ivele njengotshintsho olukhulu kule nkalo.

Uzinzo olungenakuthelekiswa nanto ukuze kusebenze ngokuhambelanayo

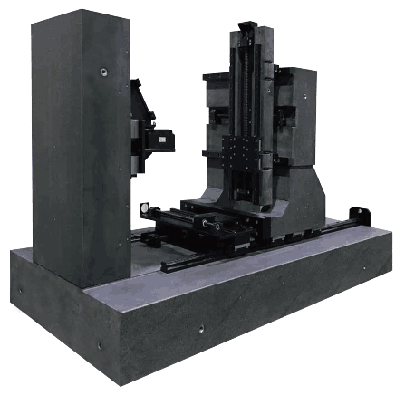

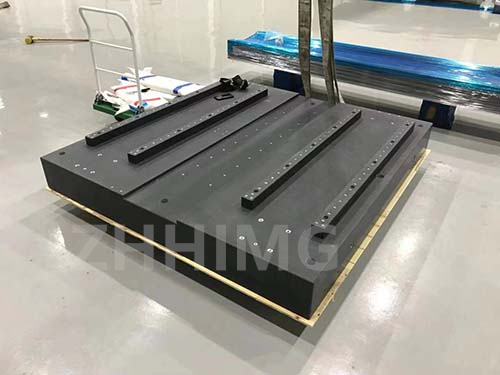

Ukuhlolwa kwe-array kufuna ukuchaneka okucacileyo, njengoko nokuba kuthe tye kancinci kunokukhokelela kwiziphumo ezingezizo okanye iziphene ezingaphoswanga. Iziseko zomatshini we-granite, ezinobunzima obuphezulu obumalunga ne-3100 kg/m³, zibonelela ngozinzo olubalaseleyo. Ngexesha lenkqubo yokuhlolwa, izixhobo zinokuba phantsi kokungcangcazela okuvela kumatshini akufutshane okanye izinto ezingqongileyo. Ulwakhiwo oluzinzileyo lwe-granite lumelana ngempumelelo nezi ngxaki zangaphandle, lugcina izinzwa zokuhlola kunye nezinto ezibonakalayo zilungelelaniswe ngokuchanekileyo. Olu zinzo luqinisekisa ukuba izixhobo zinokuskena rhoqo nangokuchanekileyo ii-arrays, kunciphisa isidingo sokuhlolwa kwakhona kunye nokuphucula umbane ngokubanzi. Umzekelo, kumzi-mveliso wokubonisa iphaneli, ukwamkelwa kweziseko zomatshini we-granite kwizixhobo zokuhlola ii-array kukhokelele ekonyukeni kwama-20% kumthamo wokuhlola wemihla ngemihla.

Ukudambisa ukudlidliza okuphezulu ukuze kusebenze ngokukhawuleza

Ukungcangcazela kunokuphazamisa kakhulu isantya sokuhlolwa kwe-array. Xa izixhobo zokuhlola zingcangcazela, isantya sokuskena sidla ngokufuneka sincitshiswe ukuze kugcinwe ukuchaneka, nto leyo ecothisa yonke inkqubo. Iimpawu zokungcangcazela kwendalo zeGranite ziluncedo olukhulu apha. Ulwakhiwo lwayo lwangaphakathi olukhethekileyo, olwenziwe ziinkozo zezimbiwa ezidibeneyo, lufunxa kwaye luchithe amandla okungcangcazela ngokufanelekileyo. Ngesiseko somatshini wegranite, izixhobo zokuhlola i-array zinokusebenza ngesantya esiphezulu sokuskena ngaphandle kokulahlekelwa kukuchaneka. Kwiziko lokuvelisa i-semiconductor, emva kokutshintsha isiseko sesinyithi sokuqala nge-granite, isantya sokuhlola se-arrays zesekethe ezidibeneyo sanda ngama-30%, nto leyo evumela imijikelo yemveliso ekhawulezayo.

Ukumelana nobushushu bexesha elide lokusebenza

Ukutshintshatshintsha kobushushu kuqhelekile kwiindawo zokwenza imveliso, kwaye kunokuchaphazela ukusebenza kwezixhobo zokuhlola uluhlu. Ezinye izinto zinokukhula okanye zinciphe ngotshintsho lobushushu, nto leyo ebangela ukungalungelelani kakuhle kwezinto kunye nokuhlolwa okungachanekanga. I-Granite ine-coefficient yokwandisa ubushushu ephantsi, nto leyo ethetha ukuba igcina imo yayo kunye nobukhulu bayo naphantsi kobushushu obahlukeneyo. Olu zinzo lobushushu luvumela izixhobo zokuhlola uluhlu ukuba zisebenze ngokuqhubekayo ngaphandle kwesidingo sohlengahlengiso olubangelwa bubushushu rhoqo. Ngenxa yoko, izixhobo zinokusebenza ixesha elide, ziphucula ukusetyenziswa kwazo kwaye ziphucule ukusebenza kakuhle. Kumgca wemveliso ophezulu, ukusetyenziswa kweziseko zoomatshini be-granite kunciphisa ixesha lokungasebenzi kwezixhobo ngenxa yeengxaki zobushushu ngama-40%.

Ukuqina okuhlala ixesha elide kwimisebenzi esebenza kakuhle nexabiso eliphantsi

Izixhobo zokuhlola ii-array zisetyenziswa rhoqo kwiindawo zoshishino, kwaye isiseko somatshini kufuneka simelane nobunzima bokusebenza kwemihla ngemihla. I-granite ihlala ixesha elide, inokumelana nokuguguleka okuhle kakhulu kunye nokungasebenzi kakuhle kweekhemikhali. Ingamelana noxinzelelo loomatshini, ukungqubana, kunye nokuvezwa kweekhemikhali okunokwenzeka kwimeko yokuvelisa. Olu kuqina luhlala ixesha elide lunciphisa ukuphindaphindeka kokutshintshwa kwesiseko kunye nokugcinwa, kunciphisa iindleko zokusebenza zizonke. Ngaphezu koko, isiseko somatshini se-granite esithembekileyo siqinisekisa ukusebenza okuzinzileyo kwexesha elide kwezixhobo zokuhlola ii-array, okuncedisa ngakumbi ekusebenzeni ngcono.

Ukuqukumbela, iziseko zomatshini wegranite zinokuphucula kakhulu ukusebenza kakuhle kwezixhobo zokuhlola uluhlu. Uzinzo lwazo, amandla okungcangcazela - ukudambisa, ukumelana nobushushu, kunye nokuqina kwazo zisebenza kunye ukuze kuqinisekiswe ukuba kuhlolwa ngokukhawuleza, ngokuchanekileyo, nangokuthembekileyo. Kubavelisi abafuna ukuphucula iinkqubo zabo zemveliso kunye nokwandisa imveliso yemisebenzi yabo yokuhlola uluhlu, ukutyala imali kwiziseko zomatshini wegranite ezikumgangatho ophezulu, ezifana nezo zibonelelwa yiZHHIMG®, sisigqibo sobulumko esinokuzisa iingenelo ezinkulu.

Ixesha leposi: Juni-10-2025