Kwimveliso echanekileyo yezinto zeglasi ze-elektroniki, i-optics, kunye noyilo lwezakhiwo, ukufikelela kunyamezelo oluqinileyo lokubhola (ngokuqhelekileyo ngaphakathi kwe-±5μm okanye ngaphezulu) kubalulekile.Iziseko zegranite ezichanekileyo ziye zavela njengesisombululo esitshintsha umdlalo, zisebenzisa iipropati zazo zomzimba ezikhethekileyo ukuphucula ukuchaneka kokugrumba kunye nokuhambelana. Eli nqaku lihlola indlela iziseko zegranite ezivumela ngayo ulawulo oluqinileyo lokunyamezelana kwimisebenzi yokugrumba iglasi.

Indima Ebalulekileyo Yokunyamezelana Ekufumbeni Iglasi

- Izixhobo zeglasi ezibonakalayofuna ukunyamezelana kwemingxunya ngaphakathi kwe-±2μm ukuze kuthintelwe iimpazamo zokurhawuzelelwa kokukhanya

- Iiphaneli zokubonisakufuneka kubekho isithuba esifanayo semingxuma ukuqinisekisa ukusebenza kwescreen sokuchukumisa

- Izixhobo zonyangoimingxuma engenamigxobhozo enolawulo oluqinileyo lobukhulu bezicelo ze-fluidic

Indlela iGranite Bases eziphucula ngayo ukuGrila ngokuchanekileyo

1. Ukudambisa ukungcangcazela okuphezulu ukuze kulungelwe ukuchaneka okuncinci

Ulwakhiwo oluxineneyo lweGranite (3,000–3,100 kg/m³) kunye neenkozo zeminerali ezidibeneyo zisebenza njengesixhobo sokufunxa uloyiko lwendalo:

- Izinga lokuthomalalisa ukungcangcazela>90% kwiifrikhwensi eziqhelekileyo zokubhola (20–50Hz)

- Inciphisa ukuxokozela kwezixhobo, ithintela ukuqhekeka okuncinci okujikeleze imingxunya yokugrumba

- Isifundo setyala: Umenzi wesiboniso osebenzisa iziseko zegranite unciphise umahluko wobubanzi bemingxuma ukusuka ku-±8μm ukuya ku-±3μm

2. Uzinzo lobushushu ukuze kubekho ukunyamezelana okuhlala kusenzeka

Xa i-coefficient ephantsi yokwandiswa kobushushu (4–8×10⁻⁶/°C), i-granite igcina uzinzo olulinganayo:

- Inciphisa ukuguquguquka kobushushu ngexesha lokugrumba ixesha elide

- Iqinisekisa ukuchaneka kwendawo yomngxuma nokuba kwiindawo apho ubushushu obutshintshatshintshayo buyi-±5°C

- Xa kuthelekiswa neziseko zentsimbi, i-granite inciphisa iimpazamo ezibangelwa bubushushu ngama-60%

3. Ubunzima obuphezulu bokuchaneka kwexesha elide

Ubunzima beGranite's Mohs obuyi-6-7 bumelana nokuguguleka ngcono kuneziseko zesinyithi okanye ezidityanisiweyo:

- Igcina umphezulu uthe tyaba (± 0.5μm/m) ngaphezulu kokusetyenziswa ixesha elide

- Inciphisa isidingo sokulungiswa rhoqo koomatshini

- Umvelisi we-semiconductor glass substrate uxele ukuba izixhobo ezisetyenziswayo ezisekelwe kwigranite zingaphantsi ngama-70%.

4. Isiseko Esiqinileyo Sokuchaneka Kwendlela Yesixhobo

Imiphezulu yegranite esemgangathweni (Ra≤0.1μm) ibonelela ngeqonga elifanelekileyo lokuxhoma:

- Ivumela ukulungelelaniswa ngokuchanekileyo kwee-axes zokubhola

- Inciphisa iimpazamo zesimo ezibangelwa kukuphambuka kwesiseko

- Iphucula ukuthambeka komngxuma ukuya kuthi ga kwi-0.01°

Isifundo seTyala: Iziseko zeGranite kwi-Optical Glass Drilling

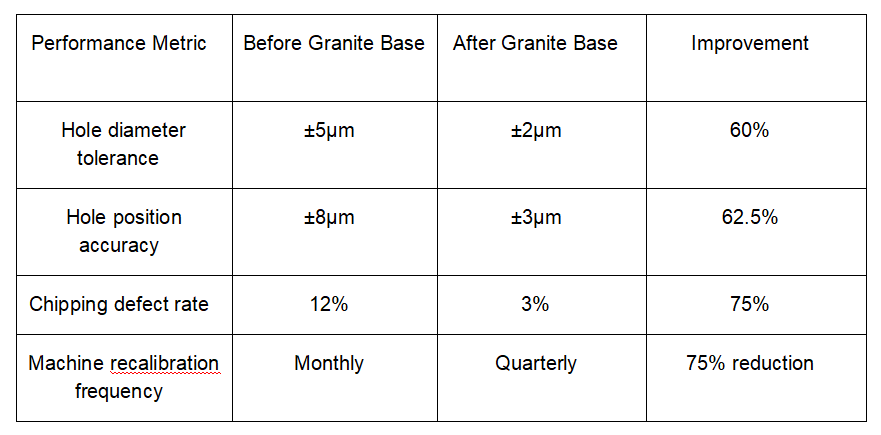

Umenzi ophambili wezinto ezibonakalayo ophuculweyo ukuya kwiziseko zegranite ezichanekileyo ze-ZHHIMG® zoomatshini babo bokugrumba iglasi be-CNC:

Iziphumo zibonisa indlela iziseko zegranite ezivumela ngayo abavelisi ukuba bahlangabezane nokunyamezelana okungqongqo okufunekayo kwiinxalenye ze-optical eziphezulu.

Izinto ezibalulekileyo eziphuculweyo ze-SEO

- Iziseko zegranite ezichanekileyo kakhuluzibalulekile ekufezekiseni ukunyamezelana okuqinileyo kwe-±5μm okanye ukubhola ngeglasi

- Ukungcangcazela kwazo, ukuzinza kobushushu, kunye neempawu zokumelana nokuguguleka zijongana nemingeni ephambili yokuchaneka

- Izifundo zetyala zibonisa ukuphucuka okukhulu ekuchanekeni kwemingxunya kunye nokuncipha kwamazinga eziphene

- Ilungele amashishini afuna ukunyamezelana okungqongqo kwezixhobo zeglasi: i-optics, izixhobo ze-elektroniki, izixhobo zonyango

Ngokudibanisa iziseko zegranite ezichanekileyo kakhulu kwiindawo zokubhola iglasi, abavelisi banokuphakamisa amandla abo okuchaneka, bahlangabezane nemigangatho yomgangatho engqongqo, kwaye bafumane ithuba lokukhuphisana kwiimarike ezinexabiso eliphezulu.

Ixesha leposi: Juni-12-2025