Iipleyiti zomphezulu wegranite ezichanekileyo bezisoloko zithathwa njengenye yezona ziseko zithembekileyo kwi-dimensional metrology. Zibonelela ngomphezulu ozinzileyo wokubhekisa wokuhlolwa, ukulinganiswa, kunye nokulinganiswa okuchanekileyo kumashishini afana nokuvelisa i-semiconductor, i-aerospace, i-CNC machining, kunye ne-optical metrology. Nangona ukubaluleka kwazo kungathandabuzeki, kukho inkxalabo enye edla ngokuvela kwiiforam zobugcisa kunye nemibuzo yabathengi:Umswakama uchaphazela njani iipleyiti zomphezulu wegranite?Ngaba ukufuma kunokubangela ukuba i-granite ijijeke okanye ilahlekelwe kukuchaneka kwayo?

Impendulo, ngokophando kunye namava eminyaka emininzi kwezoshishino, iyaqinisekisa. I-Granite, ingakumbi i-granite emnyama enoxinano olukhulu, yinto yendalo ezinzileyo kakhulu eneempawu ezincinci ze-hygroscopic. Ngokungafaniyo namatye anemingxuma njengemabula okanye i-limestone, i-granite yenziwa ngokuqiniswa kancinci kwe-magma ngaphakathi koqweqwe loMhlaba. Le nkqubo ibangela isakhiwo esixineneyo esinemingxuma ephantsi kakhulu. Ngokwendlela esebenzayo, oku kuthetha ukuba i-granite ayifunxi amanzi emoyeni, kwaye ayidumbi okanye iguquguquke kwiindawo ezifumileyo.

Enyanisweni, olu xhathiso kumswakama sesinye sezizathu eziphambili zokuba i-granite ithathe indawo yentsimbi ephosiweyo kwiindawo ezininzi zokusetyenziswa kwe-metrology. Apho i-cast iron inokugqwala okanye ibole xa ivezwe kumswakama ophezulu, i-granite ihlala izinzile ngokweekhemikhali. Kwanakwiindawo zokusebenzela ezinamazinga okufuma angaphezulu kwama-90%, iipleyiti ze-granite ezichanekileyo zigcina uzinzo lwazo kunye nokuthamba kwazo. Uvavanyo olwenziwe kwiindawo ezilawulwayo luqinisekisa ukuba ukuthamba kwepleyiti yomphezulu we-granite kuhlala ngaphakathi kokunyamezelana kwe-micrometer nokuba kukho utshintsho kumswakama womoya.

Oko kuthethiweyo, nangona igranite ngokwayo ingachaphazeleki kukufuma, imeko-bume yokulinganisa iyonke isabalulekile. Ukufuma kungenzeka kwiindawo zokusebenzela ezingalawulwa kakuhle xa amaqondo obushushu ehla ngequbuliso, kwaye nangona igranite ingagqwali, amanzi aqunyiweyo anokushiya uthuli okanye izinto ezingcolisayo eziphazamisana nokulinganisa. Izixhobo ezibekwe kwigranite, ezifana nee-dial gauges, amanqanaba e-elektroniki, okanye oomatshini bokulinganisa abadibeneyo, zihlala zinobuthathaka ngakumbi kwiimeko zokusingqongileyo kunesiseko segranite ngokwaso. Ngenxa yesi sizathu, iilabhoratri kunye neeworkshops ziyakhuthazwa ukuba zigcine ulawulo oluzinzileyo lobushushu kunye nokufuma kungekuphela nje kwigranite kodwa nakwizixhobo ezixhomekeke kuyo.

Ukumelana nokufuma okuphezulu kwegranite kubaluleke kakhulu kumashishini apho iimeko zokusingqongileyo kunzima ukuzilawula. Iifektri ze-semiconductor, izibonelelo zeenqwelo-moya, kunye neelebhu zophando zihlala zisebenza ngemigangatho engqongqo yokusingqongileyo, kodwa ukuzinza kwegranite kuqinisekisa ukhuseleko olongezelelweyo. Kwimimandla enemozulu efumileyo ngokwemvelo, ukusuka kuMzantsi-mpuma weAsia ukuya kunxweme lwaseYurophu, iipleyiti zomphezulu wegranite ziye zangqineka zithembekile ngakumbi kunezinye iindlela.

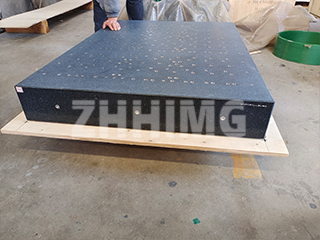

Kwi-ZHHIMG®, i-granite emnyama ekhethelwe iimveliso ezichanekileyo inika umgangatho ophezulu wokusebenza. Ngobuninzi obumalunga ne-3100 kg nge-cubic meter kunye nesantya sokufunxwa kwamanzi esingaphantsi kwe-0.1%, inika uzinzo olungenakuthelekiswa nanto. Oku kuqinisekisa ukuba ukuthamba kunye nokuchaneka kugcinwa ixesha elide lokusetyenziswa. Abathengi abasebenza kwimveliso ye-semiconductor, i-optics, i-CNC machining, kunye namaziko e-metrology kazwelonke baxhomekeke kwezi mpawu xa kufuneka ukuchaneka okupheleleyo.

Enye into ekufuneka iqwalaselwe kukugcinwa kwayo. Nangona i-granite ingachaphazeleki kukufuma, iindlela ezilungileyo zokusebenzisa zinceda ukwandisa ubomi bayo benkonzo. Ukucoca rhoqo ngelaphu elingena-lint kuthintela ukuqokelelana kothuli. Izigqubuthelo zokukhusela zinokugcina umphezulu ungenazo iinxalenye zomoya xa ipleyiti ingasetyenziswa. Ukulinganiswa rhoqo ngezixhobo eziqinisekisiweyo kuqinisekisa ukuchaneka kwexesha elide, kwaye oku kubaluleke kakhulu kwiindawo ezichanekileyo apho ukunyamezelana kunokufikelela kwinqanaba le-sub-micron. Kuzo zonke ezi meko, ukumelana okuqhelekileyo kwe-granite nokufuma kwenza umsebenzi ube lula kwaye ube nokuqikelelwa ngakumbi kunangesinyithi okanye ezinye izinto.

Umbuzo womswakama kunye neepleyiti zokuchaneka kwegranite udla ngokuvela kwinkxalabo yendalo: kubunjineli bokuchaneka, kwanempembelelo encinci yokusingqongileyo inokuba nemiphumo elinganisekayo. Ubushushu, umzekelo, buyinto ebalulekileyo ekuzinzeni kobukhulu. I-coefficient ephantsi yegranite yokwandiswa kobushushu sele iyenza ibe yenye yezona zinto zibalaseleyo zokulawula olu tshintsho. Nangona kunjalo, xa kufikwa kumswakama, iinjineli zinokuqiniseka ukuba igranite yenye yezona ndlela zithembekileyo ezikhoyo.

Kwiinkampani nakwiilabhoratri ezityala imali eninzi kwiziseko zophuhliso lwemetrology, ukukhetha izinto akupheleli nje ekusebenzeni namhlanje kodwa kukwamalunga nokuzinza kwamashumi eminyaka ezayo. I-Granite izibonakalise njengeqabane lexesha elide kulo msebenzi. Ukumelana kwayo nokufuma kuthetha ukuba inokufakelwa kwaye isetyenziswe kwiindawo ezahlukeneyo, ukusuka kwiindawo zokucoca ukuya kwiindawo zoshishino ezinzima, ngaphandle kokukhathazeka ukuba ukufuma kuya kunciphisa ukuchaneka kwayo.

Ukuqukumbela, ukufuma akusongeli uzinzo okanye ukuchaneka kweepleyiti zomphezulu wegranite. Ngenxa yendalo yayo exineneyo, engena-hygroscopic, igranite ayichaphazeleki kukufuma kwaye iyaqhubeka nokubonelela ngereferensi ezinzileyo efunekayo kwi-metrology yanamhlanje. Nangona ulawulo lokusingqongileyo lubalulekile kwizixhobo kunye nokuchaneka ngokubanzi, igranite ngokwayo inokuthenjwa ukuba ingamelana notshintsho olunxulumene nokufuma. Yingakho, kumashishini nakwihlabathi liphela, igranite ihlala iyinto ekhethwayo kwiziseko zokulinganisa ngokuchanekileyo.

Kwi-ZHONGHUI Group (ZHHIMG®), olu lwazi alupheleli nje kwithiyori kodwa lungqinwa imihla ngemihla ngentsebenziswano neenkampani zeFortune 500, iiyunivesithi eziphambili, kunye namaziko e-metrology kazwelonke. Kwiinjineli ezifuna ukuthembeka kwexesha elide, iipleyiti zomphezulu wegranite azimeli nje kuphela isiko kodwa nekamva lokulinganisa ngokuchanekileyo.

Ixesha leposi: Sep-25-2025