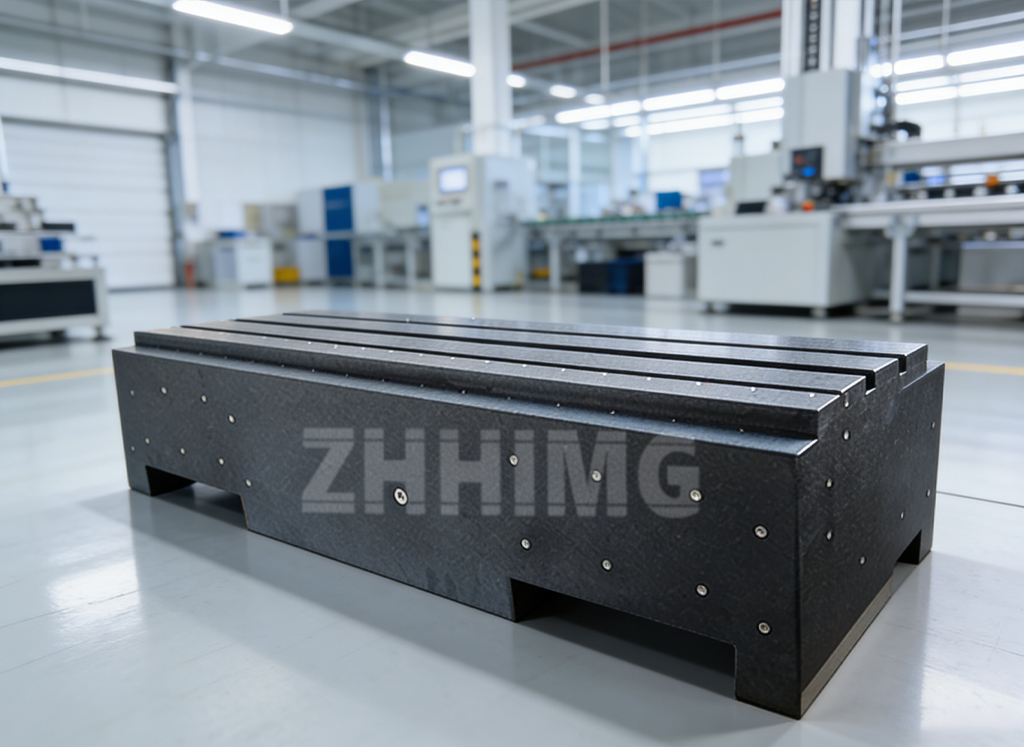

Amaqonga egranite achanekileyo awasasetyenziswa kuphela njengeendawo zokubhekisa ezingasebenzisi zixhobo. Kwimveliso yanamhlanje echanekileyo kakhulu, i-metrology, kunye nokuhlanganiswa kwezixhobo, zihlala zisebenza njengezinto zokwakha ezisebenzayo. Olu tshintsho ngokwendalo lukhokelela kumbuzo oqhelekileyo nosebenzayo ngexesha leengxoxo zokuthenga kunye noyilo: ngaba imingxunya yokufaka ingenziwa ngokwezifiso kwi-aiqonga legranite elichanekileyo, kwaye ukuba kunjalo, zeziphi imigaqo ekufuneka ilawule uyilo lwazo ukuze kuthintelwe ukuphazamisa ukuchaneka?

Impendulo emfutshane ithi ewe, imingxunya yokufaka inokwenziwa ngokwezifiso, kwaye kwizicelo ezininzi eziphambili, kufuneka ibe njalo. Amaqonga okuchaneka kwegranite ahlala efuneka ukuze adibane nee-air bearings, ii-linear motors, iindlela zokuqondisa, iinkqubo ze-optical, izixhobo, okanye ii-compositions zoomatshini ezipheleleyo. Iipateni zemingxunya eziqhelekileyo azifane zihlangabezane nezi mfuno zokudibanisa ezinzima. Uyilo lwemingxunya olwenziwe ngokwezifiso luvumela iqonga legranite ukuba libe yinxalenye ebalulekileyo yenkqubo endaweni yokuba ngumphezulu ozimeleyo.

Nangona kunjalo, ukwenza ngokwezifiso akuthethi inkululeko engenamda. I-granite iziphatha ngendlela eyahlukileyo kakhulu kwisinyithi, kwaye uyilo olungafanelekanga lwemingxunya lunokufaka uxinzelelo lwangaphakathi, lunciphise ukuqina kwesakhiwo, okanye luchaphazele kakubi ukuchaneka kwexesha elide. Yingakho abavelisi abanamava bephatha uyilo lwemingxunya njengomsebenzi wobunjineli endaweni yesicelo esilula somatshini.

Enye yezona zinto zibalulekileyo ekufuneka ziqwalaselwe kukusasazwa komthwalo. Yonke imingxunya yokufaka ingenisa uxinzelelo olukwindawo ethile kwigranite. Ukuba imingxunya ibekwe kufutshane kakhulu, kufutshane kakhulu nemiphetho, okanye ngqo phantsi kweendawo ezinomthwalo ophezulu, indawo yoxinzelelo inokugqwetha ulwakhiwo lwangaphakathi lwegranite. Nokuba ukuguquka akubonakali kwangoko, kunokubonakala ngokuhamba kwexesha njengokuhamba okuthe tyaba okuncinci. Uyilo lwemingxunya oluyilwe kakuhle luqinisekisa ukuba imithwalo evela kwizixhobo ezifakelweyo idluliselwa ngokulinganayo kumzimba wegranite endaweni yokuba ixinene kwiindawo ezimbalwa.

Ubudlelwane phakathi kwemingxunya yokufaka kunye neendawo zokuxhasa bubaluleke ngokulinganayo.Amaqonga egranite achanekileyozihlala zixhaswa kwiindawo ezithile ukunciphisa ukugoba kunye nokuphambuka komxhuzulane. Ukuba imingxunya yokufaka ibekwe ngaphandle kokujonga ezi ndawo zokuxhasa, amandla okuqinisa okanye imithwalo yokusebenza inokumelana nejometri yokuxhasa ecetywayo. Kwizicelo ezichanekileyo, olu nxibelelwano lunokubangela utshintsho olulinganiswayo ekuthambekeni komphezulu. Ngenxa yesi sizathu, uyilo loyilo lwemingxunya kufuneka luhlale luqwalasela indlela iqonga eliza kuxhaswa ngayo ngexesha lokulinganisa nokusebenza.

Ubunzulu, ububanzi, kunye nendlela yokufaka imisonto nazo zibaluleke ngaphezu kokuba abasebenzisi abaninzi belindele. I-Granite ayinyamezeli ukusonta okunamandla okanye ubunzulu obugqithisileyo ngendlela efanayo neentsimbi. Izithako, ii-bushings, okanye imikhono yesinyithi ebotshelelweyo zihlala zisetyenziselwa ukubonelela ngemisonto eqinileyo ngelixa zikhusela ilitye elijikelezileyo. Ukukhetha uhlobo lokufaka kunye nendlela yokufaka akuchaphazeli nje kuphela amandla oomatshini kodwa kunye nokuzinza kwexesha elide. Izithako ezifakwe kakubi zinokubangela iintanda ezincinci okanye uxinzelelo olushiyekileyo oluya kunciphisa ukuchaneka ngokuhamba kwexesha.

Omnye umgaqo obalulekileyo kukufana. Iipateni zemingxuma ezingalinganiyo zinokukhokelela ekusasazweni koxinzelelo olungalinganiyo, ingakumbi xa iqonga liphantsi kotshintsho lobushushu okanye imithwalo enamandla. Nangona ukungafanayo ngamanye amaxesha kungenakuphepheka ngenxa yoyilo lwezixhobo, iinjineli ezinamava zijolise ekulinganiseni indawo ebekwe kuyo imingxunya naphi na apho kunokwenzeka khona. Ukufana kunceda ekugcineni ukuziphatha kokuguquguquka okuqikelelweyo, okubalulekileyo ekugcineni ukuthamba kunye nokuchaneka kwejometri phantsi kweemeko zokwenyani.

Ukuziphatha kobushushu kufuneka kuqwalaselwe xa kusenziwa imingxunya yokufaka. I-Granite inomlinganiselo ophantsi wokwandiswa kobushushu, kodwa izinto ezifakwayo zesinyithi kunye nezinto ezifakweyo zinokukhula ngamanani ahlukeneyo. Uyilo lwemingxunya oluthintela izinto ngokuqinileyo lunokubangela uxinzelelo lobushushu kwindawo edibanisa i-granite nesinyithi. Ukuvumela intshukumo elawulwayo okanye ukukhetha izinto ezifanelekileyo zokufaka kunceda ukuthintela ukuqokelelana koxinzelelo lwexesha elide, ngakumbi kwiindawo ezinotshintsho lobushushu.

Ngokwembono yokuvelisa, ulandelelwano lwemisebenzi lubaluleke ngokufanayo noyilo ngokwalo. Kwimveliso esemgangathweni ophezulu, ukubhoboza nokufaka imingxunya yokufakela kulungelelaniswa ngononophelo neenkqubo zokusila kunye nokuleqa. Ukwenza umatshini onzima emva kokugqitywa komphezulu wokugqibela kuyingozi yokungenisa uxinzelelo okanye ukugqwetheka komphezulu. Yingakho uyilo lwemingxunya olucwangcisiweyo kufuneka luchazwe kwasekuqaleni kwinqanaba loyilo, okuvumela umenzi ukuba ayidibanise kwinkqubo yemveliso elawulwayo endaweni yokuyiphatha njengento ecingelwayo emva koko.

Ukuhlolwa nokuqinisekiswa kudlala indima ebalulekileyo xa ukwenziwa ngokwezifiso kugqityiwe. Iqonga legranite elichanekileyo elinemingxunya yokulifaka kufuneka lilinganiswe kulwakhiwo lwalo lokugqibela, kunye neendawo zokufaka ezifakiweyo kunye nomphezulu ogqityiweyo ngokupheleleyo. Iingxelo zokuhlolwa kwe-flatness kunye ne-geometry kufuneka zibonise imeko yokwenyani yokuhanjiswa endaweni yemeko ephakathi. Oku kunika ukuzithemba kokuba ukwenziwa ngokwezifiso akuzange kuyiphazamise indima yeqonga njengesalathiso sokuchaneka.

Kubasebenzisi, ukuqonda le migaqo kunceda ekubekeni ulindelo olunokwenzeka. Imingxunya yokufakelwa eyenziwe ngokwezifiso ayisiyongozi xa yenziwe ngendlela eyiyo. Ngokwahlukileyo koko, idla ngokuphucula ukuchaneka kwenkqubo ngokuqinisekisa ukulungelelaniswa okufanelekileyo, ukufakelwa okuphindaphindwayo, kunye nokudluliselwa komthwalo okuzinzileyo. Iingxaki zivela kuphela xa ulwakhiwo lwemingxunya luqhutywa lula okanye yindleko, ngaphandle kokujonga indlela izinto zegranite ezisebenza ngayo kunye neemfuno zokuchaneka.

Kwiinkqubo ezisebenzayo ezifana neziseko zezixhobo ze-semiconductor, iinkqubo zokuhamba ngokuchanekileyo, amaqonga okuhlola okubonakalayo, kunye nezigaba zomoya, amaqonga e-granite enziwe ngokwezifiso aneemingxunya ezicwangcisiweyo kakuhle aye aba yinto eqhelekileyo. Abonisa ukubaigranite echanekileyoayisiyonto ibuthathaka ekufuneka ithintelwe ekuhlanganisweni kwesakhiwo, kodwa isisiseko esinobuchule kakhulu xa siphathwa ngobuchule bobunjineli.

Ekugqibeleni, umbuzo awukokuba ingaba imingxunya yokufaka ingenziwa ngokwezifiso kwiqonga legranite elichanekileyo, kodwa kukuba ingaba yenzelwe ukuqonda okwaneleyo kokuchaneka, ukuzinza, kunye nokusebenza kwexesha elide. Xa imigaqo yoyilo ihlonitshwa kwaye ukwenziwa ngokwezifiso kwenziwa ngokuchaneka engqondweni, imingxunya yokufaka iba yinzuzo esebenzayo endaweni yokuba ibe yimvumelwano. Kubunjineli obuchanekileyo kakhulu, uyilo olucingisisiweyo lulo oluvumela igranite ukuba isebenze kungekuphela nje njengomphezulu, kodwa njengesalathiso sesakhiwo esithembekileyo kwiminyaka ezayo.

Ixesha leposi: Disemba-15-2025