Umgudu ongapheliyo wokwenza izinto zibe zincinci kwaye zisebenze kubuchwepheshe banamhlanje—ukusuka kwiiphaneli zokubonisa eziphambili ukuya kwizixhobo zesayensi ezisemgangathweni—udlule imida yezixhobo zobunjineli zemveli. Ekufuneni ukuchaneka kwe-sub-micron kwanakwinqanaba le-nanometer, iinjineli zihlala zijika ziye kwizinto ezigqityiweyo kwiminyaka eyi-1000 eyadlulayo: i-granite yendalo. Eli litye libonakala lithobekile liye laba sisiseko esingenakuxoxiswana ngaso sezixhobo ezibumba ikamva lethu ledijithali.

Imfuno yozinzo olungenamkhethe kunye nokuchaneka kumacandelo afana nokuveliswa kwe-semiconductor kunye ne-metrology ephucukileyo igxininisa ukuba kutheni izinto ze-granite ezichanekileyo zibaluleke ngakumbi. Ngokungafaniyo neentsimbi, ezichaphazeleka kakhulu kukwanda kobushushu kunye nokungcangcazela, i-granite emnyama inika i-cocktail eyahlukileyo yeempawu zomzimba ezidala imeko-bume efanelekileyo yokusebenza ngokuchanekileyo.

Isiseko seTekhnoloji yoBoniso lwePhaneli eSicaba

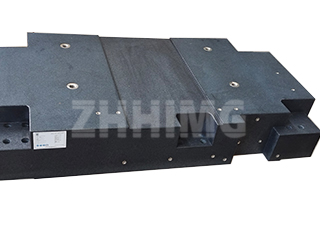

Ukwenziwa kweepaneli zokubonisa zanamhlanje—ingakumbi ezo zisekelwe kwi-Amorphous Silicon (a-Si) kunye ne-Low-Temperature Polycrystalline Silicon (LTPS) technology—kufuna oomatshini abanokugcina ukuthamba okugqwesileyo kunye nokuchaneka kwendawo kwiindawo ezinkulu. Kulapho ke izinto ze-granite mechanical ze-a-Si Array kunye ne-precision granite yezixhobo ze-LTPS Array zibaluleka khona.

Xa kuveliswa ii-substrates zeglasi ezinkulu kwiindawo zokubonisa, nokuba kuthe tye kancinci kwisakhiwo somatshini kunokuguqulela kwiimpazamo ezibizayo kunye nokulahleka kwemveliso. I-coefficient ephantsi kakhulu ye-granite yokwandiswa kobushushu (phantse isiqingatha sentsimbi) iqinisekisa ukuba isakhiwo somatshini sihlala sizinzile ngokwemilinganiselo nangona kutshintsho oluncinci lobushushu kwindawo yokucoca. Ngaphezu koko, amandla ayo angaphakathi okudambisa angaphakathi—aphezulu kakhulu kunesinyithi esityhidiweyo okanye intsimbi—abalulekile ekuthinteleni ukungcangcazela okuncinci. Ezi ngcangcazelo, ezinokuthi zingabonwa ngumntu, zinokuba yintlekele kwiinkqubo ze-lithography, etching, okanye zokubeka ezisetyenziselwa ukwenza ii-transistors ezincinci kunye neesekethe kwi-array. Ngokuchitha la mandla ngokukhawuleza, iziseko ze-granite, imiqadi, kunye nezinto ze-gantry ziqinisekisa ukuba izigaba ezinobuthathaka zihamba nolwelo, ukuchaneka okuphindaphindwayo okufunekayo kwimveliso ephezulu, enemveliso ephezulu ye-displays ezinesisombululo esiphezulu.

Ukuqina okungokwemvelo kwegranite kuthetha ukuba izixhobo zomatshini zinokuxhasa imithwalo enzima—njengeenkqubo ezinkulu ze-gantry, amagumbi okucoca, kunye neentloko zenkqubo—ngokuphambuka okuncinci, okuqinisekisa ukusebenza rhoqo kuyo yonke i-envelope yomsebenzi.

Ukuvumela ukuFunyanwa kweNzululwazi yokwenyani ngeMetrology

Ngaphandle kokuvelisa, iimpawu ezikhethekileyo zegranite echanekileyo zibaluleke kakhulu kuphando lwesayensi olusisiseko kunye ne-metrology. Umzekelo oyintloko yindima yayo kwizixhobo zohlalutyo ezinesisombululo esiphezulu, ngakumbi igranite echanekileyo kwizixhobo ze-XRD (i-X-ray Diffraction).

I-X-ray Diffraction yindlela enamandla esetyenziselwa ukufumanisa ulwakhiwo lwe-athomu kunye ne-molecular yekristale. Ukuchaneka okufunekayo kwi-goniometer—isixhobo esijikeleza isampuli kunye ne-X-ray detector—kuyamangalisa. Naluphi na ukunyakaza okanye ukungcangcazela okuchaphazela i-engile yesiganeko okanye ukufunyanwa kunokwenza idatha entsonkothileyo eqokelelweyo ingasebenzi ngokupheleleyo.

Iqonga le-metrology lenkqubo ye-XRD ephezulu kufuneka lingabi nabushushu kwaye likwazi ukuxhasa iindibano ezintsonkothileyo ze-optical kunye ne-mechanical ngozinzo olukhethekileyo. I-precision granite ibonelela nge-reference plane ethe tyaba nengalinganiyo efunekayo ukuze kufezekiswe izisombululo ze-angular ezifunekayo kuhlalutyo lwezinto eziphambili. Iipropati zayo ezingezizo zemagnethi ziluncedo olongezelelweyo, ukuqinisekisa ukuba izinzwa ze-elektroniki ezinobuthathaka kunye neenkqubo zolawulo lwe-electromagnetic ngaphakathi kwezixhobo azichaphazeleki yi-residual magnetism, ingxaki eqhelekileyo kwiintsimbi ze-ferrous.

Iingenelo Ezingenakuthelekiswa Nanto Zelitye Lendalo Kwixesha Lokuchaneka

Impumelelo yegranite kwezi zicelo zinzima ayiyonto eyenzekileyo ngengozi; yimiphumo ethe ngqo yesayensi yayo yezinto ezibonakalayo:

-

Uzinzo Lwemilinganiselo: Emva kokwaluphala kwejoloji kangangezigidi zeminyaka, ulwakhiwo lwangaphakathi lwegranite emnyama ekumgangatho ophezulu luyafana kwaye luyancipha kuxinzelelo, nto leyo enika phantse akukho ntshukumo yangaphakathi ekuhambeni kwexesha, nto leyo ibalulekileyo ekugcineni ulungelelwaniso.

-

Ukwanda kobushushu obuphantsi: Impendulo yayo encinci kutshintsho lobushushu igcina ijiyometri, uphawu olubalulekileyo kuzo zonke iinkqubo ezichanekileyo ezisebenza kwiimeko ezilawulwayo, kodwa ezingahambelani ngokupheleleyo nobushushu.

-

Ukudambisa ukungcangcazela: Ulwakhiwo lwezimbiwa zendalo lubonelela ngokudambisa okubalaseleyo okungokwemvelo, okuthintela ingxolo yoomatshini ngokukhawuleza nangokufanelekileyo kunezinyithi ezenziwe ngobunjineli.

-

Ayibolisi kwaye Ayibolisi: I-Granite ayibolisi kwaye ayibolisi, yenza kube lula ukuyigcina ikwimeko entle kwaye isusa iingxaki zokuphazamiseka kwe-electromagnetic ezinokuchaphazela izixhobo ezibuthathaka.

Ngokusebenzisa ezi mpawu, abavelisi banokufikelela kumlinganiselo we-micron kunye ne-nanometer ofunekayo ukuze kuqhutywe phambili utshintsho olutsha lwetekhnoloji. Ukusuka kwiziseko zesinyithi zemveli ukuya kwiziseko zegranite ezenziwe ngokwezifiso, ezithe tyaba kakhulu kubonisa utshintsho olusisiseko kubunjineli obuchanekileyo—ukuqaphela ukuba ukuze kubekho uzinzo lokwenyani, ngamanye amaxesha izixhobo ezindala zezona zilungileyo. Kuyo nayiphi na inkampani ezinikele ekufezekiseni ukuchaneka okungenakuthelekiswa nanto kwizixhobo ze-a-Si, LTPS, okanye ze-metrology eziphambili, i-precision granite ayisiyonto nje yokukhetha izinto; yimfuneko yokukhuphisana.

Ixesha leposi: Disemba-03-2025