Ekufuneni isizukulwana esilandelayo sokwenza i-semiconductor kunye ne-sub-micron metrology, "isiseko" kunye "nendlela" zezona zinto zimbini zibalulekileyo. Njengoko abayili boomatshini bezama ukufikelela kwi-throughput ephezulu kunye nokuphindaphinda kwinqanaba le-nanometer, ukhetho phakathi kwe-isikhokelo sokuthwala umoya wegranitekwaye isikhokelo sendabuko sokuthwala iirola siye saba sisigqibo esibalulekileyo sobunjineli. Ngaphezu koko, izinto ezisetyenziswa kwisiseko somatshini ngokwawo—ukuthelekisa igranite kunye neeseramikhi ezisebenza kakuhle—zilawula imida yobushushu kunye nokungcangcazela kwenkqubo yonke.

Ukuthelekisa izikhokelo zeGranite Air Bearing kunye nezikhokelo zeRoller Bearing

Umahluko omkhulu phakathi kwezi nkqubo zimbini usekwe kwindlela yazo yokuxhasa umthwalo kunye nokulawula ukungqubana.

Izikhokelo zoMbane woMoya weGraniteimele incopho yentshukumo engenakuphikiswa. Ngokusebenzisa ifilimu encinci yomoya ocinezelweyo—ngesiqhelo phakathi kwee-microns ezi-5 ukuya kwezingama-20—inqwelo ehambayo idada ngokoqobo ngaphezulu kwereyile yesikhokelo segranite.

-

Akukho kungqubana kunye nokuguguleka:Ngenxa yokuba akukho kuthintana ngokomzimba, akukho "kushukuma" (ukungqubana okungashukumiyo) ekufuneka koyiswe, kwaye inkqubo ayize iphelelwe lixesha. Oku kuvumela ukuskena okuhamba ngesantya esithe tye kakhulu, okungaguqukiyo.

-

Impazamo ebalwe ngokwe-avareji:Enye yezona nzuzo zibalulekileyo zee-air bearings kukukwazi kwazo "ukulinganisa" ukungalungi komphezulu wegranite, nto leyo ekhokelela ekubeni ihambe ngokuthe nkqo kune-rail ngokwayo.

-

Ucoceko:Ngaphandle kwesidingo sokuthambisa, ezi zikhokelo ziyahambelana negumbi elicocekileyo, nto leyo ezenza zibe semgangathweni wokuhlolwa kwe-wafer kunye nokuveliswa kwesiboniso sephaneli esithe tyaba.

Izikhokelo zeeRoller Bearing, ngokuchaseneyo, xhomekeke ekudibaneni ngokomzimba kweerola okanye iibhola zentsimbi ezichanekileyo.

-

Umthamo woMthwalo oPhezulu:Kwizicelo ezibandakanya imithwalo enzima okanye amandla okusika aphezulu (njengokugaywa ngokuchanekileyo), ii-roller bearings zinika ukuqina okuphezulu kakhulu kunye nomthamo wokuthwala umthwalo.

-

Ubulula bokusebenza:Ngokungafaniyo neebheringi zomoya, ezifuna iinkqubo zokuhambisa umoya ocinezelweyo nezicocekileyo kakhulu, iibheringi ezijikelezayo “ziyiplagi kwaye zidlale.”

-

Uyilo oluNcinci:Iibheringi zoomatshini zihlala zixhasa imithwalo ephezulu kwindawo encinci xa kuthelekiswa nommandla omkhulu ofunekayo kwiphedi yokuthwala umoya esebenzayo.

Nangona ii-roller bearings ziqinile kwaye zingabizi kakhulu ukuze zichaneke ngokubanzi, ii-air bearings zikhetho olungenakuthengiswa kwizicelo apho "unxibelelwano" lutshaba lokuchaneka.

Ukusetyenziswa kweZikhokelo zoMbane woMoya: Apho ukuchaneka kudibana nokufuma

Ukwamkelwa kwezikhokelo zokuthwala umoya kuye kwanda ngaphaya kwelebhu ukuya kwimveliso yemizi-mveliso emininzi.

KwiIshishini leSemiconductor, iibheringi zomoya zisetyenziswa kwi-lithography nakwi-wafer probing. Ukukwazi ukuhamba ngesantya esiphezulu ngaphandle kokungcangcazela kuqinisekisa ukuba inkqubo yokuskena ayizisi izinto ezisetyenzisiweyo kwi-nanometer-scale circuitry.

In Imifanekiso yeDijithali kunye nokuSkena okuneFomathi Enkulu, isantya esingaguqukiyo sebheriya yomoya sibalulekile. Nakuphi na “ukugoba” okanye ukungcangcazela okuvela kwibheriya yoomatshini kuya kubangela “ukubhida” okanye ukuphambuka kumfanekiso wokugqibela onesisombululo esiphezulu.

Oomatshini bokulinganisa abaQokelelweyo (i-CMM)thembela kwizikhokelo zokuthwala umoya zegranite ukuqinisekisa ukuba iprobe inokuhamba ngokulula. Ukungabikho kokungqubana kuvumela inkqubo yolawulo yomatshini ukuba iphendule ngoko nangoko kutshintsho oluncinci kakhulu lomphezulu wenxalenye elinganiswayo.

Isiseko sezinto: I-Granite vs. i-Ceramic kwiziseko zoomatshini

Ukusebenza kwayo nayiphi na inkqubo yesikhokelo kuthintelwe kukuzinza kwesiseko efakwe kuso. Kangangamashumi eminyaka, i-granite ibisoloko isetyenziswa kakhulu kushishino, kodwa iiseramikhi eziphambili (ezifana ne-Alumina okanye i-Silicon Carbide) zivelisa indawo efanelekileyo kwizicelo ezisebenza kakhulu.

Iziseko zoMatshini weGraniteihlala ilukhetho olukhethwayo kwi-90% yezicelo ezichanekileyo kakhulu.

-

Iipropati zokufunxa amanzi:I-granite ngokwemvelo ingcono kakhulu ekutsaleni ukungcangcazela okuphezulu, nto leyo ibalulekileyo kwi-metrology.

-

Ukusebenza kakuhle kweendleko:Kwiziseko ezinkulu (ukuya kuthi ga kwiimitha ezimbalwa), igranite ibiza kakhulu xa isetyenziswa kwaye isetyenziswa kuneceramics zobugcisa.

-

Ukungabi Namandla Obushushu:Ubunzima obukhulu begranite buthetha ukuba isabela kancinci kutshintsho lobushushu obungqongileyo, nto leyo enika imeko-bume ezinzileyo yokulinganisa ixesha elide.

Iziseko zoMatshini weCeramic(ingakumbi iAlumina) zisetyenziswa xa kufuneka ukusebenza "okugqwesileyo".

-

Umlinganiselo ophezulu wokuqina kobunzima:Iiseramikhi ziqinile kakhulu kunegranite ngenxa yobunzima obufanayo. Oku kuvumela ukukhawulezisa okuphezulu kunye nokucotha kwesantya seenqanaba zokuhamba ngaphandle kokuphazamisa isiseko.

-

Uzinzo Olugqithisileyo Lobushushu:Ezinye iiseramikhi zine-coefficient of thermal expansion (CTE) engaphantsi nangakumbi kunegranite, kwaye i-thermal conductivity yazo ephezulu ivumela isiseko ukuba sifikelele kwi-thermal equilibrium ngokukhawuleza.

-

Ubunzima:Iiseramikhi azikwazi ukukrweleka kwaye ziyamelana nokukhukuliseka kweekhemikhali, nangona zibuthathaka kwaye zibiza kakhulu xa zenziwe ngeendlela ezinkulu.

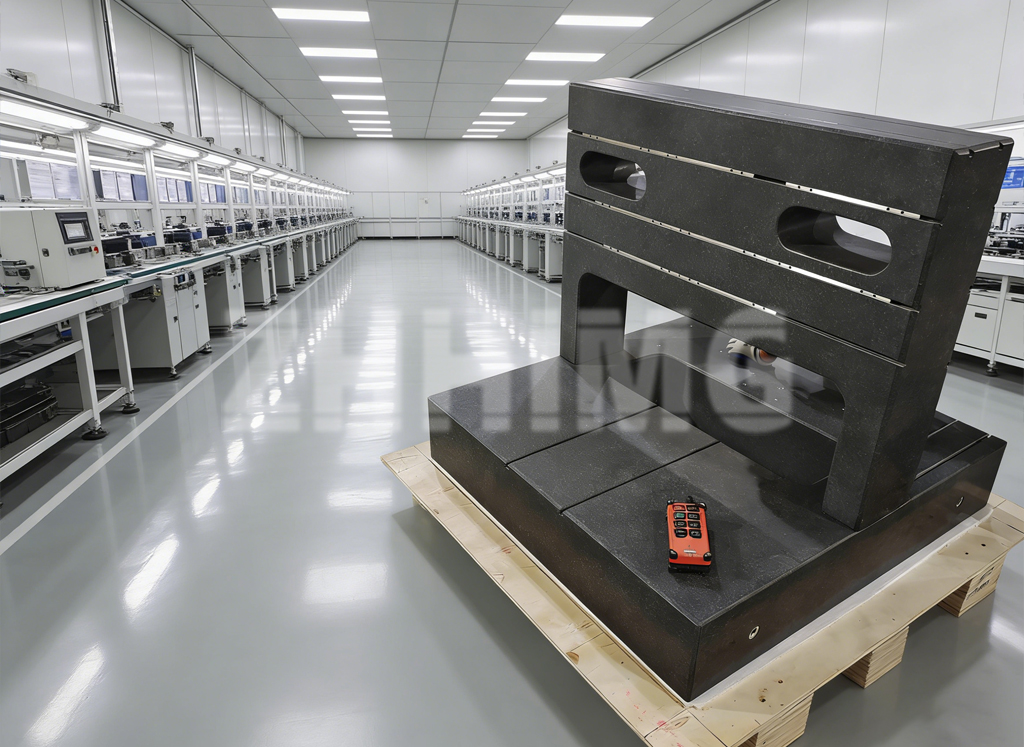

Ukuzibophelela kweZHHIMG kwiSayensi yezinto eziphathekayo

Apha kwi-ZHHIMG, sikholelwa ukuba isisombululo esingcono asifane sibe yindlela enye efanela bonke. Iqela lethu lobunjineli ligxile ekudityanisweni kwezi teknoloji. Sihlala sisebenzisa ubunzima bokudambisa ukungcangcazela kwesiseko segranite ukuxhasa intshukumo engenakuphikiswana yesikhokelo sokuthwala umoya, ngamanye amaxesha sifaka izinto zokufaka zeseramikhi kwiindawo ezibalulekileyo zokuguguleka okuphezulu okanye ukuqina okuphezulu.

Njengomvelisi okhokelayo, sinikezela kwimarike yehlabathi ukuqiniseka kwejoloji yegranite yezinga eliphezulu kunye nobuchwephesha beenkqubo zokuhamba zanamhlanje. Indawo yethu yokuvelisa idibanisa ubuchule bendabuko bokutsalela ngesandla—isakhono esifunekayo ukuze kufezekiswe ubunzulu obufunekayo kwiibheringi zomoya—kunye nomatshini we-CNC ophucukileyo kunye ne-interferometry yelaser.

Isiphelo: Uyilo lwempumelelo yakho

Ukukhetha phakathi kwegranite kunye ne-ceramic, okanye phakathi kweebheringi zomoya kunye nee-mechanical, ekugqibeleni kulawula imida yokusebenza kwetekhnoloji yakho. Kwiinjineli kwicandelo le-aerospace, i-semiconductor, kunye ne-metrology, ukuqonda ezi ntengiselwano ngundoqo wokuvelisa izinto ezintsha. I-ZHHIMG Group iyaqhubeka nokutyhala imida yoko kunokwenzeka kwintshukumo echanekileyo, iqinisekisa ukuba umatshini wakho umi kwisiseko sozinzo olupheleleyo kwaye uhamba ngokuchanekileyo okungenakuthelekiswa nanto.

Ixesha leposi: Jan-22-2026