Ukusukela ukuchaneka kakhulu yeyona nto iphambili kwimveliso yanamhlanje. Kumacandelo aqala ekuvelisweni kwee-semiconductor kunye ne-precision metrology ukuya ekucutshungulweni kwe-laser kunye ne-CNC machining ephezulu, ukuzinza kunye nokuchaneka kwesiseko somatshini kubaluleke kakhulu. Isiseko esingenasiphako siguqulela ngokuthe ngqo kwiimpazamo ezidityanisiweyo kwimveliso yokugqibela.

Esi sikhokelo sibalulekileyo sibonelela abavelisi kunye neengcali zokuthenga ngesakhelo esifunekayo ukuze bakwazi ukuhamba kwimarike enzima kunye nokukhusela i-Top Rated Custom Iziseko zoMatshini weGranite, ukuqinisekisa ukusebenza kwexesha elide kunye nokuthembeka kwezixhobo zabo ezixabisekileyo.

Ukuqonda Indima Yesiseko Somatshini

Isiseko somatshini singaphezulu kakhulu kunesakhiwo esixhasayo esilula; sisixhobo esibalulekileyo esilawula i-geometry kunye nokusebenza okuguquguqukayo kwenkqubo yonke. I-Granite sisixhobo esikhethwayo kwizicelo ezichanekileyo kakhulu ngenxa yeempawu zayo eziphambili: i-coefficient yokwandisa ubushushu obuphantsi, amandla aphezulu okudambisa, kunye nozinzo olukhethekileyo. Ezi mpawu zinciphisa imiphumo yokuguquguquka kobushushu kunye nengxolo yokungcangcazela, ezizezona zizathu zimbini ziphambili zokungachaneki komatshini.

Izalathisi zokusebenza eziphambili zeziseko ezikumgangatho ophezulu

Xa kuvavanywa isiseko somatshini wegranite esenziwe ngokwezifiso, abathengi kufuneka bagxile kwiimitha zobunjineli ezithile, ezinokubalwa ezichaza umgangatho kunye nokusebenza. Ukuthobela imigangatho yamazwe ngamazwe, njengemigangatho ye-DIN 876 okanye ye-ISO, akunakuxoxiswana ngayo; kwizixhobo ezichanekileyo kakhulu, inqanaba lokunyamezela elingcono kuneGrade 00 lihlala lifuneka, liqinisekiswa zizixhobo ezichanekileyo zemetrology ezifana nee-laser interferometers. Umgangatho wegranite eluhlaza, edla ngokuba yintlobo emnyama enoxinano oluphezulu, ubalulekile, njengoko uxinano oluphezulu kunye nesakhiwo sengqolowa esincinci sihambelana nokuzinza okungcono kobukhulu. Ngaphezu koko, amandla esiseko okususa ukungcangcazela koomatshini ngokukhawuleza, okulinganiswa ngumlinganiselo ophezulu wokudambisa, kubalulekile ekuthinteleni ukusasazwa kweempazamo ezivela kumandla okusika okanye kwiintshukumo zeemoto. Okokugqibela, ekubeni uninzi loomatshini abaphambili bafuna iijometri ezizodwa, amandla omthengisi okudibanisa izinto ezifana neebheringi zomoya, iimoto ezithe ngqo, kunye neereli zesikhokelo ngqo kumphezulu wegranite ngokuchaneka kwe-sub-micron luphawu oluchaza isiseko esikumgangatho ophezulu.

Umahluko Phakathi Kweziseko Ezilungileyo NezingaPhantsi

Umahluko ophambili phakathi kwesiseko somatshini wegranite esikumgangatho ophezulu nesikumgangatho ophezulu kunye nesiseko esiphantsi asikuko kuphela ukupholisha kokugqibela, kodwa nakwinkqubo yonke yokuvelisa kunye nesiseko sayo.

Isiseko esingcono sisebenzisa ukulepha okuchanekileyo kakhulu, okuhlala kusenziwa ngamanqanaba amaninzi okanye ngerobhothi, njengendlela yaso ephambili yokwenza izinto, ngokungafaniyo nokusila okulula kunye nokukrwela ngesandla okusetyenziswa kwiimveliso eziphantsi. Le nkqubo iphambili ixhaswa luLawulo loMgangatho oluqinileyo, olubandakanya imaphu ye-laser interferometer kunye nokuqinisekiswa ngaphakathi kweendawo ezilawulwa bubushushu obuqinileyo, okubonelela abathengi ngeengxelo zokulinganisa ezilandelekayo. Ngokwahlukileyo koko, iziseko ezincinci zixhomekeke ekutshekishweni kwe-dial gauge esisiseko kunye nolawulo olulinganiselweyo lokusingqongileyo. Umgangatho wezinto zexabiso lomnye umahluko ophambili: iziseko eziphezulu zenziwe ngegranite emnyama eqinisekisiweyo, endala ngokwendalo, enoxinano oluphezulu, eqinisekisiweyo ukuba inika uzinzo oluqinisekisiweyo lwexesha elide ngenxa yokunciphisa uxinzelelo olufanelekileyo. Iziseko eziphantsi zisebenzisa igranite ekumgangatho ophantsi enokuba neengxaki zangaphakathi, ukuguga okungafanelekanga, kwaye ngenxa yoko ithambekele ekubeni "irhubuluze" okanye utshintsho lobukhulu ngokuhamba kwexesha. Okokugqibela, amandla okuhlanganiswa ngokwezifiso abalulekile; umthengisi osemgangathweni ophezulu uqinisekisa ukuba izinto ezifakwe ngomatshini ochanekileyo (ezifana ne-T-slots okanye imingxunya enemisonto) zidityaniswe ngaphandle kokubeka emngxunyeni ubuninzi, ngelixa ukufakwa okungafanelekanga kwiziseko eziphantsi kunokubangela uxinzelelo lwezinto zasekuhlaleni okanye ukungalingani.

Iindleko Ezifihlakeleyo Zokuyekelela Kwimilinganiselo Esisiseko

Ukukhetha isiseko segranite esiphantsi kuzisa iingozi ezinkulu zexesha elide ezidlula kakhulu naziphi na iindleko zokuqala. Impembelelo ekhawulezileyo neyona inzulu ikukunciphisa ukuChaneka koMatshini. Isiseko esingenalo ukuqina okanye uzinzo olufunekayo lunegalelo ngokuthe ngqo kwiimpazamo ezicwangcisiweyo kwijiyometri yomatshini, okwenza kube nzima ukuhlangabezana nokunyamezela okujoliswe kuko kwiindawo ezinexabiso eliphezulu. Ekuhambeni kwexesha, amandla okudambisa anganeleyo anokukhokelela kwi-Premature Wear and Tear kwiindawo ezibizayo zomatshini, kubandakanya izikhokelo ezithe ngqo, iibheringi, kunye neespindles, nto leyo ekhokelela ekwandeni kweendleko zokulungisa kunye nexesha lokungasebenzi. Ngaphezu koko, ukuba izinto zegranite azizange zigugiswe ngokufanelekileyo ukuze kuncitshiswe uxinzelelo lwangaphakathi, isiseko sinokufumana iGeometric Creep, utshintsho oluhamba kancinci kodwa olubalulekileyo kwimo eyenza umatshini wonke ungabi luncedo kumsebenzi ochanekileyo kakhulu, ofuna uhlengahlengiso olubizayo okanye ukutshintshwa ngokupheleleyo. Ekugqibeleni, isiseko esingaphantsi komgangatho sibeka emngciphekweni umgangatho wemveliso, sonyusa amaxabiso enkunkuma, kwaye sonakalise kakhulu udumo lomenzi ngokuchaneka.

Ukukhetha uMboneleli Ofanelekileyo: Ingqwalasela kwiSikali kunye nobuGcisa

Ukuchonga umthengisi onobunzulu bobuchwephesha obufunekayo kunye namandla okuvelisa kubalulekile. Khangela iinkampani ezinerekhodi eqinisekisiweyo, ezisebenza phantsi kweenkqubo zolawulo lomgangatho ezingqongqo, kwaye ezinokujongana neemfuno zokwenziwa ngokwezifiso ezigqithisileyo.

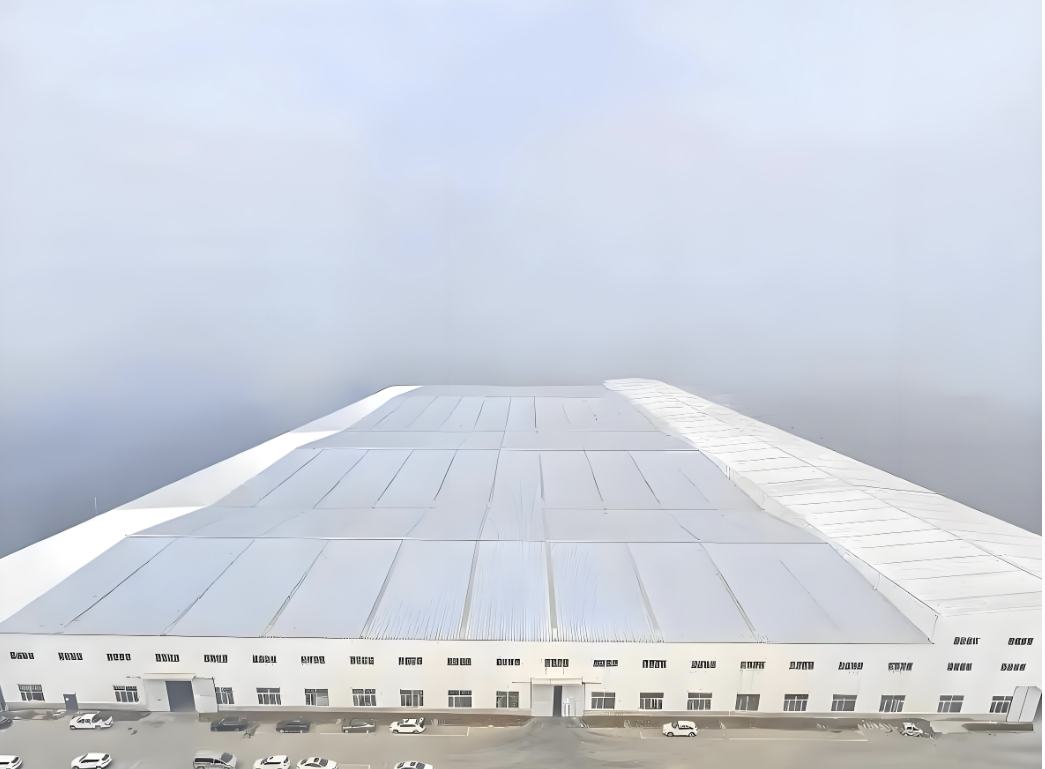

Umlinganiselo we-ZHHIMG kwi-Non-Metallic Ultra-Precision

Njengenkokeli eyaziwayo kweli candelo likhethekileyo,I-Zhonghui Intelligent Manufacturing (Jinan) Co., Ltd. (ZHHIMG®)ibonisa amandla afunekayo ukuvelisa iziseko zoomatshini ezikumgangatho ophezulu ngokwenene. Ukususela ngeminyaka yoo-1980, i-ZHHIMG ibigxile kwizixhobo zokwenza izinto ezingezizo ezesinyithi, ingakumbi izixhobo ezinkulu zegranite.

Imigangatho yabo yokusebenza ihambelana ngqo nemigangatho yamazwe ngamazwe, ebonakaliswa ziziqinisekiso ezifanayo ze-ISO 9001 (uLawulo loMgangatho), i-ISO 14001 (uLawulo lweNdalo), i-ISO 45001 (iMpilo noKhuseleko emsebenzini), kunye nophawu lwe-EU CE. Olu qinisekiso lunemiba emininzi luqinisekisa imveliso eyenziwe kungekuphela nje ngokweenkcazo zobugcisa eziphezulu kodwa kunye noxanduva lokusingqongileyo kunye nokhuseleko lwabasebenzi engqondweni.

Iingenelo zobuGcisa kunye neMveliso

Iingenelo eziphambili ze-ZHHIMG zijongana ngqo neemfuno ezifunwa kakhulu zezixhobo zegranite ezenziwe ngokwezifiso: I-Extreme Scale Capability ivumela ukuba zicubungule izixhobo ezinkulu kakhulu, zenze iziqwenga zegranite ezenzelwe wena ukuya kuthi ga kwiitoni ezili-100 kwiyunithi enye okanye iimitha ezingama-20 ubude. Lo mthamo ubalulekile koomatshini besizukulwana esilandelayo, njengabo basetyenziswa kwimveliso yokubonisa ngefomathi enkulu okanye kwi-aerospace simulation. Ngaphezu koko, umthamo wabo we-High-Volume Processing, ofikelela kwiiseti ezili-10,000 ngenyanga, uqinisekisa isantya kunye nokuhambelana kwee-odolo ezinkulu ngaphandle kokuphazamisa ukuchaneka okufunekayo kwizinto ngazinye. Ngaphaya kobukhulu obulula kunye nemilo, ubuchule be-ZHHIMG bufikelela kwi-Comprehensive Customization, ekhethekileyo ekudityanisweni okuntsonkothileyo kwezinto zoomatshini nezombane, kubandakanya ukucutshungulwa ngokuchanekileyo kwemingxunya, iindawo zokufaka, kunye noyilo lobunzima bolwakhiwo emzimbeni wegranite, ukuqinisekisa utshintsho olungenamthungo ukuya kwindibano yokugqibela yesixhobo somatshini.

Isiphelo: Ukutyala imali kwi-Precision

Isigqibo sokuthenga isiseko somatshini wegranite esenziwe ngokwezifiso sisicwangciso-mali sexesha elide ekuchanekeni, uzinzo, kunye nokukwazi ukuvelisa kwixesha elizayo. Ngokugxila kwimigaqo yobunjineli esele imiselwe—ngokukodwa, amanqanaba okunyamezelana okuqinileyo, umgangatho ophezulu wezinto eziphathekayo, kunye nomthamo oqinisekisiweyo womthengisi wokwenza ngokwezifiso ezinkulu nezintsonkothileyo—abathengi banokukhetha ngokuzithemba iiSeko zoMatshini zeGranite ezenziwe ngokwezifiso eziBalaseleyo eziya kusebenza njengesiseko esingagungqiyo sezicelo zabo ezibalulekileyo.

Ukuze ufunde okungakumbi malunga nezixhobo zegranite ezenziwe ngokwezifiso kunye nezisombululo zokwenza izinto ezichanekileyo kakhulu, nceda undwendwele iwebhusayithi esemthethweni:https://www.zhhimg.com/

Ixesha leposi: Disemba-29-2025