Kwihlabathi le-ultra-precision metrology, isixhobo sokulinganisa igranite-esifana nepleyiti yomphezulu, i-straightedge, okanye i-master square-sisingqinisiso esipheleleyo seplani. Ezi zixhobo, zigqitywe ngobuchule ngumatshini kunye nokuzinikela ngesandla, zityala ukuzinza kwazo kunye nokuchaneka kwelitye elixineneyo, elidala ngokwendalo ezenziwe ngalo. Nangona kunjalo, ixesha lokuphila kunye nokugcinwa kokuchaneka kwezi zixhobo zibalulekileyo akuqinisekiswanga; zisisiphumo semo engqongileyo elawulwayo kunye nezenzo zokusebenza ngobuchule.

KwiQela le-ZHONGHUI (ZHHIMG®), siyaqonda ukuba ngelixa i-granite yethu ephezulu ibonelela ngesiseko esikhethekileyo, izinto ezininzi ezisecaleni lomsebenzisi zinempembelelo ngokuthe ngqo ukuba isixhobo esichanekileyo sigcina ixesha elingakanani ukuchaneka kwaso okuqinisekisiweyo. Ukuqonda ezi zinto kubalulekile ekukhuseleni utyalo-mali lwakho.

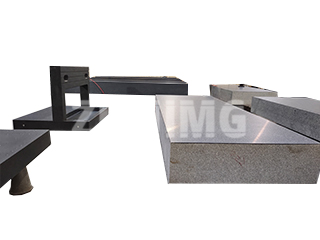

Izoyikiso eziphambili kubomi obude beGranite

Ukuthotywa kweqonga lokulinganisa igraniti kudla ngokuvela kuxinzelelo lomatshini kunye nokusingqongileyo kunokusilela kwezinto.

- Ukusasazwa koMthwalo ongafanelekanga: Uxinzelelo olugqithisileyo okanye olungalinganiyo, ngakumbi xa lugxininiswe kwindawo enye yeqonga, kunokukhokelela ekunxibeni kwendawo okanye nokuba kuncinci, ukuguqulwa kwexesha elide. Oku kudla ngokubonwa xa ii-workpieces ezinzima zibekwe ngokuphindaphindiweyo kwindawo enye, okubangela ukuba indawo yokusebenza yecandelo iphulukane nokuthe tyaba kwayo okufanelekileyo.

- Ungcoliseko lokusiNgqongileyo: Itshiphu enye, ukucheba isinyithi, okanye isuntswana lothuli olurhabaxa lunokusebenza njengephepha lesanti phakathi kwegraniti kunye nomsebenzi. Indawo yokusebenzela engacocekanga ayibonisi nje iimpazamo zokulinganisa ngokukhawuleza kodwa ikhawulezisa kakhulu ukunxiba komphezulu wegraniti, inciphisa ngokuthe ngqo ubomi bayo benkonzo echanekileyo.

- Isixhobo soMsebenzi kunye noMgangatho woMphezulu: Ukwakhiwa kunye nokugqitywa kwezinto ezilinganisiweyo zidlala indima ebalulekileyo kumazinga okunxiba. Izinto ezithambileyo ezifana nobhedu kunye ne-aluminiyam zibangela ukukrazuka okuncinci, ngelixa izinto eziqinileyo, ngakumbi intsimbi etyhidiweyo, zinokubeka i-granite ekubeni iguge kakhulu. Ngaphaya koko, izixhobo zokusebenza ezinoburhabaxa bomphezulu obuthathaka (ukugqiba okurhabaxa) ziqhele ukukrwela iqonga legranite eliphothiweyo, lonakalise ngokusisigxina inqwelomoya.

- Ukusetyenziswa Kakubi ngokuSebenzayo kunye noQhagamshelwano oluHluphekileyo: Ubulukhuni bendalo obusezantsi begranite, ngelixa buluncedo kwiipropathi zayo ezingezizo-magnetic nezingadlekiyo, buyenza ibe lula ukunxitywa ngenxa yokukhuhlana. Ubuchwephesha obufana nokuhamba ngokugqithisileyo ngasemva-na-phambili kwesixhobo sokusebenza okanye isixhobo sokubhekisela kuyo yonke indawo-kunokuphakamisa nokubeka-zazisa ukukhuhlana okuthoba ngokukhawuleza umaleko ophezulu wegranite. Oku kuqinisekisa umgaqo: izixhobo zokulinganisa igranite zizixhobo, kungekhona iibhentshi zokusebenza.

Ukwenziwa ngokuChaneka: uGunyaziso loomatshini abaNcedisayo

Ukwenziwa kwesixhobo sokulinganisa i-granite esikumgangatho ophezulu, esichaneke kakhulu sixhomekeke kakhulu ekuchanekeni koomatshini abancedisayo njengoko yenzayo kwilitye ngokwalo.

Ukuqinisekisa ukuchaneka komda kwemveliso yokugqibela, onke amacandelo omatshini wokulungisa amatye kufuneka agcinwe ngokwemigangatho ye-metrology. Oku kufuna ukujongwa ngokuphindaphindiweyo kobukhulu bendibano yomatshini kunye nokuthotyelwa ngokungqongqo kwimisebenzi yobugcisa begumbi lokucoca. Ngaphambi kokuba naluphi na ulungiso lwamatye olusesikweni luqale, izixhobo kufuneka ziqhube uvavanyo ukuze ziqinisekise umsebenzi oqhelekileyo. Ukusebenza komatshini ophosakeleyo akugcini nje ukubeka ingozi kumonakalo kodwa kunokukhokelela kwinkunkuma yezinto ezixabisekileyo, ezikhethiweyo zegranite.

Ukugcina izinto zangaphakathi zoomatshini—ukusuka kwibhokisi yokusonta ukuya kwiindlela zokuphakamisa—kubalulekile. Ukuthambisa kufuneka kufakwe ngokuchanekileyo kuyo yonke imiphezulu yokukhwelana, kubandakanywa iibheringi kunye nokudityaniswa kwezikrufu zelothe, phambi kwawo nawuphi na umsebenzi. Uqhagamshelo kufuneka lungabi namanqaku okanye i-burrs, kwaye nayiphi na irusi yangaphakathi okanye ungcoliseko kufuneka icocwe ngokucokisekileyo kwaye iphathwe nge-anti-rust coatings ukuthintela izinto zangaphandle ekuphazamiseni inkqubo yokusila.

Indima ebalulekileyo yoMgangatho weNdibano yeMechanical

Umgangatho womatshini osetyenziselwa ukucubungula i-granite unxulumene ngokuthe ngqo nokuzinza kwemveliso yokugqibela ye-granite. Oku kufuna ingqalelo engqongqo kwiinkcukacha zokuhlanganisa oomatshini:

- Ukuthwala kunye nokutywinwa kweMfezeko: Iibheringi kufuneka zicocwe ngokucokisekileyo ukuze kususwe ii-anti-rust agents kwaye zitshekishwe ukujikeleza okugudileyo phambi kokuhlanganiswa. Ukunyanzeliswa okufakwe ngexesha lofakelo lokuthwala kufuneka kube ngokulinganayo, ukulinganisa, kunye nokufanelekileyo, ukuphepha uxinzelelo kwiindlela zomdyarho kunye nokuqinisekisa ukuba ubuso besiphelo buxhomekeke kwi-shaft. Amatywina kufuneka acinezelwe ngokunxuseneyo kwimijelo yawo ukuthintela ukujijeka, okuya kwazisa ukudlala kunye nokungazinzi kumatshini wokulungisa.

- Ukulungelelaniswa kweeNkqubo zeMotion: Kumacandelo afana neenkqubo ze-pulley, i-axs kufuneka ihambelane ngokugqibeleleyo kwaye ihambelane nokuthintela ukunyanzeliswa okungalinganiyo, i-belt slippage, kunye nokugqoka okukhawulezileyo-konke okukhokelela kwi-vibration ephazamisa ukuchithwa ngokuchanekileyo kwegranite. Ngokufanayo, ukunyameka kunye noqhagamshelwano oluyinyani lweendawo zokukhwelana kuqhagamshelo lomatshini kufuneka ziqinisekiswe kwaye zilungiswe ukuba kukho nayiphi na i-deformation okanye i-burrs efunyenweyo.

Isishwankathelo, isixhobo sokulinganisa i-granite sisisigxina kodwa silungiswe kakuhle. Ubomi bayo obukhethekileyo yimveliso yegranite emnyama ekumgangatho ophezulu ye-ZHHIMG®, edityaniswe nolawulo olungqongqo phezu kococeko olusebenzayo, ukuphathwa ngendlela eyiyo kwesixhobo sokusebenza, kunye nokugcinwa ngononophelo koomatshini abachanekileyo okuzisa ukuchaneka kwayo kokugqibela, okuqinisekisiweyo.

Ixesha lokuposa: Oct-30-2025