Kwimimandla yemizi-mveliso ephezulu efana nokuvelisa ngokuchanekileyo kunye nokucubungula i-semiconductor, ukuzinza kwezixhobo zemveliso kumisela ngokuthe ngqo umgangatho weemveliso kunye nokusebenza kakuhle kwemveliso. Nangona kunjalo, iziseko zesinyithi zemveli zinokuba neengxaki zokuguquguquka kobushushu xa zisebenza ixesha elide okanye xa ubushushu bendalo butshintsha, nto leyo ebangela ukunyuka kweendleko kunye nokuncipha kokuthenjwa kwabathengi. Ngokwedatha yophando lweshishini, izinga leziphene zeemveliso ezibangelwa kukuguquguquka kobushushu kweziseko zesinyithi zesinyithi linokufikelela ngaphezulu kwe-30% kwezinye iinkqubo zemveliso ezinobushushu obuphantsi, nto leyo ethintela kakhulu uphuhliso lwamashishini.

Isizathu esiyintloko sengxaki yokuguquguquka kobushushu beziseko zesinyithi esityhidiweyo sikwiimpawu zazo zezinto. Umlinganiselo wokwandiswa kobushushu besinyithi esityhidiweyo uphezulu. Xa izixhobo zisebenza ixesha elide kwaye zivelisa ubushushu, okanye xa ubushushu obujikelezayo butshintsha, isiseko sesinyithi esityhidiweyo siya kudlula kutshintsho olungalawulekiyo lobukhulu. Ukuguquguquka okuncinci okunjalo, kwiimeko zokucubungula ngokuchanekileyo, kwanele ukukhokelela kuthotho lweziphumo ezibi ezifana nokuphambuka kokuchaneka kokucubungula, ukuphazamiseka kwepateni yokukrola, kunye neempazamo zokuhlanganisa izinto, ekugqibeleni okubangela ukuba inani elikhulu leemveliso libe zizinto ezilahliweyo ngenxa yokungaphumeleli ukuhlangabezana nemigangatho yomgangatho.

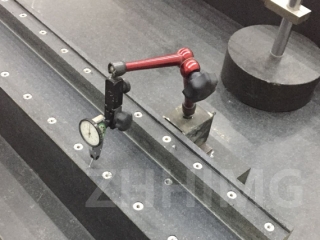

Ukuphendula kule meko ibuhlungu kushishino, kwavela iqonga lokugrumba igranite le-ZHHIMG, linika amashishini isisombululo sokuqina kobushushu. Iqonga lokugrumba igranite le-ZHHIMG lenziwe ngegranite yendalo, enenzuzo ekhethekileyo ekuzinzeni kobushushu. I-coefficient yokwandiswa kobushushu begranite iphantsi kakhulu, yi-1/5 ukuya kwi-1/10 kuphela yesinyithi esityhidiweyo. Ingagcina izinga eliphezulu lozinzo kwindawo enotshintsho olukhulu lobushushu, iphephe ngempumelelo iimpazamo zokucubungula ezibangelwa kukuguquguquka kobushushu. Nokuba yindawo yokusebenzela yokuvelisa ubushushu obuphezulu okanye indawo yokusebenza enomahluko omkhulu wobushushu phakathi kwemini nobusuku, iqonga lokugrumba igranite le-ZHHIMG linokuqinisekisa ukusebenza ngokuchanekileyo kwezixhobo kwaye ngokusisiseko liphucule isivuno semveliso.

Ukongeza ekuzinzeni kwayo okumangalisayo kobushushu, iqonga lokugrumba i-ZHHIMG granite likwaneenzuzo ezininzi. Linobunzima obuphezulu kunye nokumelana nokuguguleka okunamandla, linokumelana nemithwalo yokucubungula enamandla aphezulu, kwaye ubomi balo benkonzo bude kakhulu kunobo beziseko zesinyithi. Izinto zegranite zendalo zisebenza kakuhle kakhulu ekufunxeni i-shock, ezinokufunxa ngokufanelekileyo ukungcangcazela okuveliswa ngexesha lokusebenza kwezixhobo kwaye ziqinisekise ngakumbi ukuchaneka kokucubungula. Okwangoku, umphezulu weqonga uye waphathwa ngokuchanekileyo, kunye nobunzima obunokufikelela kwinqanaba le-micrometer, ukubonelela ngesiseko esiqinileyo nesithembekileyo sokucubungula ngokuchanekileyo.

Amatyala amaninzi okusetyenziswa kwamashishini aqinisekisile ngokupheleleyo ukusebenza okugqwesileyo kweqonga lokusika igranite le-ZHHIMG. Emva kokwazisa iqonga lokusika igranite le-ZHHIMG, izinga leziphene zeshishini elithile lokuvelisa i-semiconductor lehle kakhulu ukusuka kwi-25% yokuqala ukuya kwi-5%, ukusebenza kakuhle kwemveliso kwanda nge-30%, iindleko zemveliso zancitshiswa kakhulu, kwaye ukhuphiswano lwemarike lwaphucuka kakhulu.

Ukuba ishishini lakho likhathazwa yingxaki yesivuno ebangelwa kukuguquka kobushushu beziseko zesinyithi, iqonga lokugrumba i-ZHHIMG granite ngokungathandabuzekiyo lolona khetho lufanelekileyo. Ngenxa yokusebenza kwalo okuzinzileyo nokuthembekileyo, liya kukunceda uphume kwiingxaki zemveliso kwaye ufezekise uphuculo oluphindwe kabini kumgangatho wemveliso kunye nokusebenza kakuhle kwemveliso.

Ixesha leposi: Meyi-14-2025