Kwinkqubo yokuvelisa iibhetri ze-lithium-ion, inkqubo yokugquma, njengekhonkco eliphambili, ichaphazela ngokuthe ngqo ukusebenza kunye nokhuseleko lweebhetri. Uzinzo lweqonga lokulawula intshukumo lomatshini wokugquma ibhetri ye-lithium ludlala indima ebalulekileyo ekuchanekeni kokugquma. I-Granite kunye nesinyithi esityhidiweyo, njengezixhobo zeqonga ezisetyenziswa rhoqo, umahluko ekuzinzeni kwazo okulinganayo utsale ingqalelo enkulu. Eli nqaku liza kuhlalutya ngokunzulu uphuculo olubalulekileyo ekuzinzeni okulinganayo kwe-granite xa kuthelekiswa nesinyithi esityhidiweyo kwiqonga lokulawula intshukumo loomatshini bokugquma ibhetri ye-lithium ngokusebenzisa iipropati zezinto, idatha yovavanyo kunye namatyala okusetyenziswa okusebenzayo.

Iimpawu zezinto ezibonakalayo zimisela isiseko sozinzo

Isinyithi esitshisiweyo, njengesixhobo semveli soshishino, sasisetyenziswa kakhulu kwicandelo lamaqonga olawulo lokuhamba ngenxa yokusebenza kwayo okuhle kakhulu kokuphosa kunye neenzuzo zeendleko. Nangona kunjalo, izixhobo zesinyithi esitshisiweyo zineziphene ezingokwemvelo. Ulwakhiwo lwaso lwangaphakathi luqulathe inani elikhulu le-flake graphite, elilingana neentanda zangaphakathi kwaye liya kunciphisa ubulukhuni bezinto. Okwangoku, i-coefficient yokwandiswa kobushushu besinyithi esitshisiweyo iphezulu, malunga ne-10-12 × 10⁻⁶/℃. Phantsi kokuqokelelwa kobushushu obuveliswa kukusebenza kwexesha elide kwe-lithium battery coating, ithambekele ekuguqukeni kobushushu. Ukongeza, kukho uxinzelelo lokuphosa ngaphakathi kwesinyithi esitshisiweyo. Ngokuhamba kwexesha, ukukhululwa koxinzelelo kuya kubangela utshintsho olungenakuguqulwa kubungakanani beqonga, okuchaphazela ukuchaneka kwengubo.

I-Granite yinto yendalo eyenziwe ngeenkqubo zejoloji kwiminyaka engamakhulu ezigidi. Ulwakhiwo lwayo lwangaphakathi lwekristale luxinene kwaye lufana, kwaye lunozinzo oluphezulu olungokwemvelo. I-coefficient yokwandiswa komgca wegranite yi-0.5-8×10⁻⁶/℃ kuphela, eyi-1/2-1/3 yentsimbi ephosiweyo, kwaye ayikhathali kakhulu kutshintsho lobushushu. Okwangoku, i-granite iqinile kwisitayile, inamandla okucinezela aphezulu njenge-1,050-14,000 yeekhilogram ngesentimitha yesikwere. Ingamelana ngempumelelo neempembelelo zamandla angaphandle kunye nokungcangcazela, inika isiseko esiqinileyo nesizinzileyo seqonga lokulawula intshukumo. Akukho xinzelelo lushiyekileyo ngaphakathi kuyo, kwaye ayizukubangela utshintsho kubukhulu ngenxa yokukhululwa koxinzelelo, iqinisekisa uzinzo kubukhulu beqonga ukusuka kwisiseko sezinto.

Idatha yovavanyo iqinisekisa umahluko wokusebenza

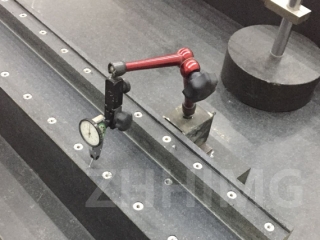

Ukuze kuthelekiswe ngokubonakalayo umahluko kukuzinza kobukhulu phakathi kwegranite kunye nesinyithi esityhidiweyo, iqela lophando lenze uvavanyo olukhethekileyo. Kukhethwe amaqonga amabini olawulo lokushukuma komatshini wokugquma ibhetri ye-lithium oneenkcukacha ezifanayo, enziwe ngegranite kunye nesinyithi esityhidiweyo ngokulandelelana, kwaye avavanywa phantsi kweemeko ezifanayo zokusingqongileyo. Olu vavanyo lulinganise imeko yokusebenza yomatshini wokugquma ibhetri ye-lithium. Ngokusebenzisa izixhobo ngokuqhubekayo, utshintsho lobungakanani beqonga kwiindawo ezahlukeneyo zamaxesha lwajongwa.

Iziphumo zovavanyo zibonisa ukuba emva kokusebenza okuqhubekayo iiyure ezingama-24, ngenxa yobushushu obuveliswa kukusebenza kwezixhobo, ubushushu bomphezulu weqonga lezinto zesinyithi eziphothiweyo bunyuke malunga ne-15℃, nto leyo ebangele ukwanda kwe-0.03mm kubungakanani becala lobude beqonga. Phantsi kweemeko ezifanayo, umahluko wobukhulu beqonga legranite phantse awubonakali kangako, kwaye uluhlu lokuguquguquka kobukhulu balo lungaphantsi kwe-0.005mm. Emva kweeyure ezili-1000 zovavanyo lokuguga olude, ngenxa yokukhululwa koxinzelelo lwangaphakathi kunye nokuqokelelwa kokuguquguquka kobushushu, impazamo yokuthamba kweqonga lesinyithi eziphothiweyo yanda ukusuka kwi-0.01mm yokuqala ukuya kwi-0.05mm. Impazamo yokuthamba kweqonga legranite ihlala igcinwe ngaphakathi kwe-0.015mm, kwaye inzuzo yokuzinza kobukhulu icacile.

Impumelelo emangalisayo kwizicelo ezisebenzayo

Kwimveliso yokwenyani yeshishini elikhulu lokuvelisa iibhetri ze-lithium, kwakusetyenziswa amaqonga okulawula ukuhamba kwesinyithi. Njengoko ixesha lokusebenza kwezixhobo lalisanda, ukuchaneka kokugquma kwehla kancinci kancinci, nto leyo eyabangela ukuba ubukhulu bokugquma bungalingani, ukungaguquguquki kakuhle kwamaphepha e-electrode ebhetri, kunye nezinga lemveliso elingalunganga lifike kwi-8%. Ukusombulula le ngxaki, ishishini litshintshe amaqonga okulawula ukuhamba kwezinye izixhobo ngezinto zegranite.

Emva kokutshintshwa, uzinzo lobukhulu bezixhobo luye lwaphucuka kakhulu. Ngexesha lomjikelo wemveliso weenyanga ezintandathu, umatshini wokugquma osebenzisa iqonga legranite uhlala ugcina impazamo yobukhulu bokugquma ngaphakathi kwe-±2μm, kwaye izinga lemveliso elingalunganga liye lehla kakhulu laya ngaphantsi kwe-3%. Okwangoku, njengoko amaqonga egranite engadingi ukulinganiswa ngokuchanekileyo kunye nokugcinwa rhoqo njengamaqonga esinyithi, asindisa amashishini inani elikhulu leendleko zokugcinwa kwezixhobo kunye nexesha lokungasebenzi minyaka le, kwaye anyusa ukusebenza kakuhle kwemveliso ngaphezulu kwe-15%.

Ukuqukumbela, ekusebenziseni iqonga lokulawula intshukumo loomatshini bokugquma ibhetri ye-lithium, i-granite, eneempawu zayo ezibalaseleyo zezinto, iphumelela kakhulu kwisinyithi esityhidiweyo ngokwemilinganiselo yokuzinza. Nokuba ngokwembono yendalo yezinto, idatha yovavanyo, okanye iziphumo zesicelo esisebenzayo, i-granite inika isiqinisekiso esithembekileyo semveliso echanekileyo nezinzileyo yeenkqubo zokugquma ibhetri ye-lithium. Ngokuphuculwa okuqhubekayo kweemfuno zomgangatho wemveliso kushishino lwebhetri ye-lithium, amaqonga okulawula intshukumo enziwe nge-granite ngokuqinisekileyo aya kuba lukhetho oluphambili kushishino.

Ixesha lokuthumela: Meyi-22-2025