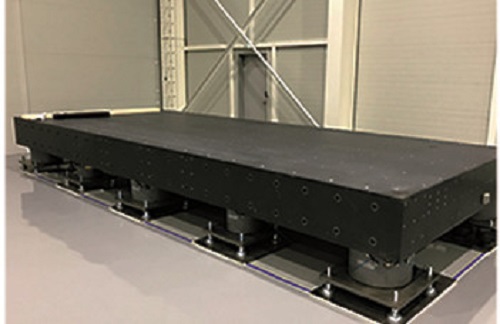

Kwishishini leebhetri ze-lithium, njengesixhobo esiphambili semveliso, ukuzinza kweqonga lokuhamba lomatshini wokugquma kudlala indima ebalulekileyo kumgangatho wemveliso yeebhetri ze-lithium. Kwiminyaka yakutshanje, amashishini amaninzi avelisa iibhetri ze-lithium afumanise ukuba xa ephucula izixhobo zawo, emva kokutshintsha isiseko sesinyithi sendabuko ngesiseko segranite, ukuzinza kweqonga elihambayo kufikelele kwinqanaba eliphezulu. Ngokweemvavanyo zokwenyani, izinga lokuphucula uzinzo lifikelele kwi-200%. Okulandelayo, siza kujonga izizathu zalo.

Umahluko kwiipropati zezinto ezibonakalayo ubeka isiseko sozinzo

Uzinzo lobushushu: I-Granite ineenzuzo ezibalulekileyo

Ngexesha lokusebenza komatshini wokugquma ibhetri ye-lithium, izinto ezinje ngokusebenza kwemoto kunye nobushushu obuveliswa kukungqubana zinokubangela ukuguquguquka kobushushu obujikeleze izixhobo. I-coefficient yokwandiswa kobushushu besinyithi esityhidiweyo imalunga ne-12×10⁻⁶/℃, kwaye ubungakanani bayo buyatshintsha kakhulu xa ubushushu butshintsha. Umzekelo, xa ubushushu bunyuka nge-10℃, isiseko sesinyithi esityhidiweyo esingangemitha e-1 sinokwandiswa nge-120μm. I-coefficient yokwandiswa kobushushu be-granite iphantsi kakhulu, kuphela (4-8) ×10⁻⁶/℃. Phantsi kweemeko ezifanayo, ukwandiswa kwesiseko se-granite esingangemitha e-1 ubude yi-40-80μm kuphela. Ukuguquguquka okuncinci kobushushu kuthetha ukuba kwindawo yemveliso enotshintsho oluqhelekileyo lobushushu, isiseko se-granite sinokugcina ngcono ukuchaneka kokuqala kweqonga elihambayo kwaye siqinisekise uzinzo lwenkqubo yokugquma.

Ukuqina nokusebenza kokunciphisa: I-Granite ingcono kakhulu

Ukuqina kumisela amandla ezinto zokuxhathisa ukuguquka, ngelixa ukusebenza kokudambisa kunxulumene nokusebenza kakuhle kokufunxa amandla okungcangcazela. Nangona isinyithi esityhidiweyo sinobulukhuni obuthile, sinesakhiwo segrafiti esiqhekekileyo ngaphakathi. Phantsi kwesenzo sexesha elide soxinzelelo olutshintshanayo oluveliswa kukusebenza kwezixhobo, sithambekele ekugxininiseni uxinzelelo, okukhokelela ekuguqulweni nasekuchaphazeleni uzinzo lweqonga. Ngokwahlukileyo koko, igranite iqinile ngobunjani, inesakhiwo sangaphakathi esixineneyo kunye nokuqina okugqwesileyo. Isakhiwo sayo esikhethekileyo seminerali siyinika ukusebenza okugqwesileyo kokunciphisa ubushushu, okuyenza ikwazi ukuguqula ngokukhawuleza amandla okungcangcazela abe ngamandla obushushu ukuze asasazeke. Izifundo zibonise ukuba kwindawo yokungcangcazela ye-100Hz, igranite inokunciphisa ngempumelelo ukungcangcazela kwimizuzwana eyi-0.12, ngelixa isinyithi esityhidiweyo sifuna imizuzwana eyi-0.9. Xa umatshini wokugquma ibhetri ye-lithium usebenza ngesantya esiphezulu, isiseko segranite sinokunciphisa kakhulu ukuphazamiseka kokungcangcazela kwintloko yokugquma, siqinisekise ubukhulu obufanayo nobuhambelanayo bokugquma.

Inkxaso yedatha yobungakanani yokuphucula uzinzo

Uvavanyo lokungcangcazela: Umahluko we-amplitude wahlukile

Amaziko obuchwephesha enze uvavanyo lokungcangcazela kwiiplatifomu zokuhamba koomatshini bokugquma ibhetri ye-lithium abaxhotyiswe ngeziseko zesinyithi kunye neziseko zegranite ngokwahlukeneyo. Xa umatshini wokugquma usebenza ngokuqhelekileyo kwaye isantya sibekwe kwi-100m/min, kusetyenziswa isenzi sokungcangcazela esichanekileyo ukulinganisa ubukhulu beendawo ezibalulekileyo zeplatifomu. Iziphumo zibonisa ukuba ubukhulu beplatifomu yokuhamba yesiseko sesinyithi yi-20μm kwicala le-X-axis kunye ne-18μm kwicala le-Y-axis. Emva kokutshintshwa ngesiseko segranite, ubukhulu be-X-axis behle baya kwi-6μm kwaye obe-Y-axis behle baya kwi-5μm. Ukusuka kwidatha ye-amplitude, kunokubonwa ukuba isiseko segranite sinciphise ubukhulu be-amplitude yeplatifomu ehambayo kwiindlela ezimbini eziphambili malunga ne-70%, kunciphisa kakhulu impembelelo yokungcangcazela ekuchanekeni kwengubo kwaye kubonelela ngobungqina obuqinileyo bokuphucula uzinzo.

Ukugcinwa kokuchaneka kwexesha elide: Ukukhula kancinci kweempazamo

Ngexesha lovavanyo lokusebenza ngokugquma oluqhubekayo lweeyure ezisi-8, ukuchaneka kwendawo yeqonga kwajongwa ngexesha langempela. Xa kusetyenziswa isiseko sesinyithi esityhidiweyo, impazamo yendawo yeqonga iyanda kancinci ngokuhamba kwexesha. Emva kweeyure ezisi-8, impazamo yendawo eqokelelweyo yee-axes ze-XY ifikelela kwi-±30μm. Impazamo yendawo yeqonga elishukumayo elinesiseko segranite emva kweeyure ezisi-8 yi-±10μm kuphela. Oku kubonisa ukuba ngexesha lenkqubo yemveliso yexesha elide, isiseko segranite sinokugcina ukuchaneka kweqonga ngcono, siphephe ngokufanelekileyo ukuphambuka kwendawo yokugquma okubangelwa kukushukuma kokuchaneka, kwaye siqinisekise ngakumbi inzuzo yaso yokuzinza.

Uzinzo lokuqinisekiswa kwesiphumo sokwenyani semveliso luphuculwe

Kumgca wokwenyani wemveliso yeshishini elithile lokuvelisa iibhetri ze-lithium, iziseko zesinyithi eziphothiweyo zezinye iimatshini zokugquma zaphuculwa zaba ziziseko zegranite. Ngaphambi kokuphuculwa, izinga lesiphene lemveliso laliphezulu ukuya kwi-15%, kunye neziphene eziphambili kubandakanya ubukhulu bokugquma obungalinganiyo kunye nokuphambuka kokufaka emaphethelweni ephepha le-electrode. Emva kokuphuculwa, izinga lesiphene leemveliso lehle kakhulu laya kwi-5%. Emva kohlalutyo, kungenxa yokuba isiseko segranite siphucula uzinzo lweqonga elihambayo ukuba inkqubo yokugquma iba ngokuchanekileyo kwaye ilawuleke, inciphisa ngempumelelo iziphene zemveliso ezibangelwa ziiplatifomu ezingazinzanga. Oku kubonisa ngokupheleleyo impembelelo entle yesiseko segranite kumgangatho wemveliso kwiimashini zokugquma iibhetri ze-lithium.

Ukuqukumbela, nokuba kungokuhlalutywa kwethiyori kweempawu zezinto eziphathekayo, idatha yovavanyo lobungakanani, okanye impendulo yempembelelo kumgca wemveliso, kubonisa ngokucacileyo ukuba ukuphuculwa kozinzo kweqonga lokushukuma komatshini wokugquma ibhetri ye-lithium kusetyenziswa isiseko segranite xa kuthelekiswa nesiseko sesinyithi esityhidiweyo kunokufikelela kwi-200%. Kumashishini okuvelisa iibhetri ze-lithium alandela umgangatho ophezulu kunye nomthamo ophezulu, isiseko segranite ngokungathandabuzekiyo lukhetho oluphambili lokuphucula ukusebenza komatshini wokugquma.

Ixesha leposi: Meyi-19-2025