Embindini weshishini lokuvelisa oomatshini kunye ne-metrology kukho isixhobo esisisiseko: iCast Iron Surface Plate. Ezi zixhobo zesalathiso ezicwangcisiweyo zibalulekile ekuhlolweni ngokuchanekileyo kwemisebenzi, ukubhala ngokuchanekileyo, kunye nokusebenza njengemilinganiselo ezinzileyo yokuseta izixhobo zomatshini. Kwi-ZHHIMG®, ukuzibophelela kwethu ekuchanekeni kakhulu kudlulela ngaphaya kweemveliso zethu ezidumileyo zegranite ukuya kwimigangatho eqinileyo elawula zonke izixhobo ezibalulekileyo ze-metrology. Ukuqonda inkqubo ecokisekileyo—ukusuka ekubunjweni ukuya ekufakweni—kubaluleke kakhulu ekuqinisekiseni umgangatho kunye nobude bexesha lale mpahla ibalulekileyo yomgangatho wevenkile.

Uqeqesho lwe-Foundry: Amanyathelo okuzikhusela kwi-Cast Iron Casting

Ukwenziwa kweepleyiti zomphezulu wesinyithi esisemgangathweni ophezulu kuqala ngoqeqesho oluphezulu kwindawo yokusekwa. Abaqhubi kufuneka banamathele ngokungqongqo kwindlela elawulwayo yokuhamba kweenkqubo ejolise ekubeni lula kwaye kufane. Oku kubandakanya ukuyila iipateni ezinciphisa inani leendawo zokwahlulwa kunye neentloko zesanti ngelixa kuqinisekiswa ii-engile ezifanelekileyo zokwahlula kunye nobukhulu bodonga obuguqukayo ngokutyibilikayo. Ukukhetha inkqubo efanelekileyo yokubopha kubalulekile; kufuneka kuqinisekiswe ukuqina ngokulandelelana, okukhokelela ekubunjweni okucwangciswe ngokulinganayo, okuncitshiswe uxinzelelo.

Okubalulekileyo kukuba, umgangatho wentlabathi yokubumba uchaphazela ngokuthe ngqo ukuthungwa kokugqibela. Umxube wentlabathi kufuneka ube nokuvuleka okugqwesileyo, amandla amanzi, ukunyibilika, iplastiki, kunye nokuguguleka. Oku kufezekiswa ngokulandela ngokungqongqo ulandelelwano lokutya kwezinto—isanti endala, isanti entsha, udongwe, umgubo wamalahle, kunye namanzi—kunye nokulawula ixesha lokuxuba ngokuchanekileyo kwimizuzu emithandathu ukuya kwesixhenxe. Isanti exutyiweyo emva koko iyaphumzwa kwaye ihluzwe ukuze iphucule ukuvuleka kwayo kunye nokunyibilika kwayo ngaphambi kokusetyenziswa.

Inkqubo yokugalela ngokwayo ifuna ukugxila okungagungqiyo. Isinyithi esinyibilikisiweyo kufuneka sigonywe ngokufanelekileyo kwaye sisuswe ngokupheleleyo ngaphambi kokuba kuqale ukugalela. Ukuhamba okuqhubekayo nokuzinzileyo kubalulekile ukuthintela iziphene ezifana nokukhukuliseka kwesanti kunye nokwenziwa kwemingxunya yesanti. Ukusabela ngokukhawuleza kuyo nayiphi na into evuzayo kuyimfuneko ukuze kuthintelwe iziphene ezinzulu ezifana nokuvalwa okubandayo kunye nokugalela okungaphelelanga. Okokugqibela, inkqubo yokucoca ngononophelo iqinisekisa ukuba i-cast epholileyo isuswa kwi-mold ngaphandle komonakalo, nto leyo ebangela ukuba umphezulu ungabi naziphene zokuqala.

Uyilo, Iziphene, kunye nobuninzi: Ukuqinisekisa uBume beSakhiwo

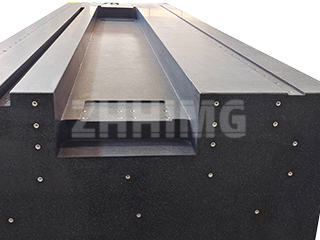

Iqonga lesinyithi elisemgangathweni ophezulu lenzelwe ukuhlala ixesha elide. Ngokuqhelekileyo lenzelwe ukuba libe zizakhiwo ezimacala mabini okanye ezinje ngebhokisi, iindawo zazo zokusebenza zihlala zisikwere okanye zixande. Ukuqina kwesakhiwo kuxhomekeke kakhulu kwiimpawu ezifana neendonga zamacala kunye neembambo zokuqinisa, ekufuneka zilinganiswe ngokuchanekileyo ngokusekelwe kumthamo ofunekayo wokuthwala umthwalo kunye nomgangatho ochanekileyo. Ukuphakama kwezi mbambo zokuqinisa—nokuba zi-half-rib, full-rib, okanye flat-rib—kubonelela ngoxinzelelo kunye nenkxaso efunekayo.

Nokuba kukho ulawulo oluqinileyo lokuphosa, kusenokubakho iziphene ezincinci. Kwiiplatifomu ezingaphantsi kokuchaneka kweBanga "0," imigangatho yeshishini ivumela ukulungiswa kokuvalelwa kwemingxuma emincinci yesanti (ububanzi obungaphantsi kwe-14 mm) kusetyenziswa izinto ezifanayo, ukuba ubunzima bezinto zokulungisa buphantsi kunentsimbi ejikelezileyo. Nangona kunjalo, umphezulu wokusebenza kufuneka ekugqibeleni ungabi naziphene ezinkulu, kubandakanya imifantu, iimbobo, ukufakwa kwe-slag, kunye nemingxuma yokuncitshiswa, kwaye umphezulu wokuphosa kufuneka uthambe ngepeyinti enamathele ngokuqinileyo. Ukukhetha iplatifomu eye yaluphala ngokwendalo okanye unyango lobushushu bokwenziwa kubaluleke kakhulu, njengoko ezi nkqubo zinciphisa uxinzelelo lwangaphakathi kwaye zithintela ukuguquguquka kwe-diagonal kwixesha elizayo.

Ukufakwa kunye nokugcinwa: Ukugcina ukuchaneka

Iqonga lesinyithi esibunjiweyo, nokuba linjani na umgangatho walo, lichanekile kuphela njengokufakelwa kwalo. Kufuneka lilinganiswe ngokuthe tye kunye nomthwalo osasazwa ngokulinganayo kuzo zonke iindawo zokuxhasa, ngokuqhelekileyo kufezwa kusetyenziswa iinyawo ezihlengahlengiswayo zebracket exhasayo. Le nkqubo yokulinganisa, ekhokelwa linqanaba le-elektroniki elichanekileyo okanye inqanaba lesakhelo, ibalulekile ekufezekiseni ukuchaneka kwayo okulinganisiweyo.

Ukuze kugcinwe ukuchaneka, imeko-bume ibalulekile. Ubushushu bokusebenza kufuneka bugcinwe malunga nama-20℃ (± 5℃), kwaye ukungcangcazela kufuneka kuthintelwe ngokungqongqo. Ngaphambi kokuba kuqalwe umsebenzi, umphezulu kufuneka ucocwe ngononophelo ukuze kususwe isanti eseleyo, ii-burrs, ioyile, kunye nomhlwa, njengoko nezinto ezincinci ezingcolisayo ziphazamisa ukuchaneka. Umphezulu osemgangathweni ophezulu, okanye ogudileyo, ubalulekile ukuze uhlale ixesha elide.

Ngokusetyenziswa ngokufanelekileyo nangokugcina ngononophelo—ukuphepha iindawo ezifumileyo, ezirhabaxa, okanye ezishushu kakhulu—ukuchaneka komphezulu wokusebenza weqonga lesinyithi esityhidiweyo kunokugcinwa iminyaka emibini okanye ngaphezulu. Ulwakhiwo lweqonga ngokwalo lunokuhlala amashumi eminyaka. Ukuba ukuchaneka kwehla, kunokubuyiselwa ngokupheleleyo ngokulungiswa ngobuchule okanye ngokutsha umphezulu (ukukrwela). Ukuhlolwa rhoqo ngokuchasene nomgangatho walo wokulinganisa kuyimfuneko, njengoko ukusebenzisa ipleyiti engaphantsi komgangatho kuya kukhokelela ekuphambukeni komlinganiselo kwaye kuchaphazele umgangatho wemveliso yokugqibela.

Njengesixhobo esibalulekileyo kwicandelo leemoto, eleenqwelo moya, elezixhobo, neleemishini ezinzima, iqonga lesinyithi lingqina lokuba ukuchaneka kwakhiwe ukusuka ezantsi ukuya phezulu.

Ixesha leposi: Oktobha-31-2025