Iziseko zegranite ziya zithandwa kakhulu kwihlabathi loomatshini be-CNC (Computer Numerical Control) ngenxa yokuzinza kwazo okugqwesileyo, ukuqina, kunye nokuchaneka. Njengoko abavelisi befuna ukuphucula ukusebenza koomatshini babo be-CNC, kubalulekile ukuqonda iintlobo ezahlukeneyo zeziseko zegranite.

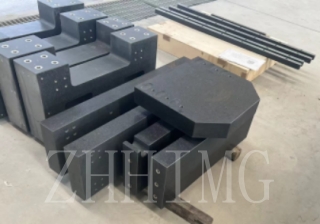

Enye yezona ntlobo ziphambili zeziseko zegranite yi **isiseko segranite esiqhelekileyo**, esisetyenziswa rhoqo kwizicelo zoomatshini ngokubanzi. Zenziwe ngegranite esemgangathweni ophezulu, ezi ziseko zibonelela ngesiseko esiqinileyo esinciphisa ukungcangcazela kunye nokwanda kobushushu. Olu zinzo lubalulekile ekufezekiseni ukuchaneka okuphezulu kwimisebenzi yoomatshini.

Olunye uhlobo sisiseko segranite esenziwe ngokwezifiso, esinokulungiswa ngokweemfuno ezithile zomatshini. Iziseko ezenziwe ngokwezifiso zinokuyilwa ukuze zilungele ubungakanani obukhethekileyo, amandla obunzima, kunye noqwalaselo lokufakelwa. Oku kuguquguquka kwenza abavelisi bakwazi ukwenza ngcono ukuseta kwabo kwe-CNC kwimisebenzi ethile, ukuphucula ukusebenza kakuhle kunye nokuchaneka ngokubanzi.

**Iziseko zokulinganisa igranite** nazo zifanelekile ukujongwa, ingakumbi kwizicelo zemetrology. Ezi ziseko ziyilwe ngendlela echanekileyo yokuba tyaba kunye nokugqitywa komphezulu, nto leyo eyenza ukuba zilungele ukusetyenziswa kwiimashini zokulinganisa ezidibeneyo (iiCMM). Iimpawu zegranite ezisemgangathweni ziqinisekisa ukuba ezi ziseko zokulinganisa zibonelela ngemilinganiselo ethembekileyo nephindaphindwayo, nto leyo ebalulekileyo kwinkqubo yokulawula umgangatho.

Ukongeza, iziseko zegranite ezidityanisiweyo** ziye zavela njengendlela yanamhlanje. Ezi ziseko zidibanisa igranite nezinye izinto, ezifana nee-polymer resins, ukwenza isiseko esikhaphukhaphu kodwa esomeleleyo. Iziseko zegranite ezidityanisiweyo zibonelela ngeenzuzo zegranite yendabuko ngelixa zinciphisa ubunzima, zenza kube lula ukuziphatha nokuzifaka.

Ngamafutshane, ukuphonononga iintlobo ezahlukeneyo zeziseko zegranite zomatshini we-CNC kutyhila iindlela ezahlukeneyo zokuhlangabezana neemfuno ezithile zoomatshini. Nokuba ukhetha isiseko segranite esisemgangathweni, esenziwe ngokwezifiso, esenziwe ngokulinganisa, okanye esidityanisiweyo, abavelisi banokuphucula kakhulu ukusebenza kunye nokuchaneka kwemisebenzi yabo ye-CNC ngokukhetha isiseko esifanelekileyo.

Ixesha leposi: Disemba-20-2024