Kwicandelo lokwenziwa kwe-PCB (Printed Circuit Board), ukuchaneka kokugrumba kumisela ngokuthe ngqo ukusebenza kombane kunye nesantya sokuphuma kwebhodi yesekethe. Ukusuka kwiitships zefowuni eziphathwayo ukuya kwiibhodi zesekethe ze-aerospace, ukuchaneka kokuvuleka kwenqanaba ngalinye le-micron kubalulekile kwimpumelelo okanye ukungaphumeleli kwemveliso. Iziseko zegranite, ezineempawu zazo ezikhethekileyo kunye neenzuzo zesakhiwo, ziba "liqabane legolide" lezixhobo zokugrumba ze-PCB, ziqhuba ukuchaneka kweshishini ukuya kubude obutsha.

I. Inzuzo Yemvelo: Ukusebenza okuzinzileyo kubeka isiseko sokuchaneka

Uzinzo olubalaseleyo lobushushu

Ngexesha lenkqubo yokubhola ye-PCB, ubushushu obuveliswa kukujikeleza ngesantya esiphezulu kwe-drill bit bunokufikelela kwi-60-80℃. Ukwandiswa kwezinto zesinyithi eziqhelekileyo ngenxa yobushushu kunokubangela ukuba indawo yokubhola itshintshe ngokulula. I-coefficient yokwandiswa kobushushu be-granite yi-4-8×10⁻⁶/℃ kuphela, eyi-1/5 kuphela yentsimbi. Oku kuthetha ukuba nokuba ubushushu obujikeleze umhlaba butshintsha ngokukhawuleza, ukuguquguquka kwesiseko se-granite kunokunganakwa. Emva kokuba umenzi othile webhodi yesekethe amkele isiseko se-granite, impazamo yendawo yokubhola yehlisiwe ukusuka kwi-±50μm ukuya kwi-±10μm, nto leyo ephucula kakhulu ukuhambelana kokusebenza kombane kwebhodi yesekethe.

2. Ukusebenza kwenyikima okunamandla kakhulu

Ukungcangcazela okuphezulu komatshini wokugrumba ngamawaka eenguqu ngomzuzu kunokuchaphazela ukuma nkqo kwento yokugrumba, nto leyo ebangela ukuphambuka kobubanzi bemingxuma. Iimpawu zendalo zokudambisa ngaphakathi kwegranite ziyenza ikwazi ukufunxa ngaphezulu kwe-90% yokungcangcazela kwezixhobo (20-50Hz). Idatha elinganisiweyo ibonisa ukuba emva kokufaka isiseko segranite, ubukhulu bokungcangcazela kwento yokugrumba buyehla ukusuka kwi-15μm ukuya kwi-3μm, kwaye ixabiso leRa loburhabaxa bodonga lwemingxuma egrunjiweyo lehle ngama-60%, nto leyo enciphisa kakhulu iingxaki ze-burrs kunye ne-delamination yodonga lwemingxuma.

3. Ukumelana nokuguguleka okuhlala ixesha elide

Ukubhola nge-PCB ngumsebenzi oqhutywa rhoqo kwaye uneemfuno eziphezulu kakhulu zokuxhathisa ukuguguleka komphezulu wesiseko. I-Granite inobunzima be-Mohs obuyi-6 ukuya kwi-7 kwaye ukumelana kwayo nokuguguleka kuphindwe kathathu kunentsimbi eqhelekileyo. Umzi-mveliso omkhulu we-PCB usebenzise iziseko ze-granite ngokuqhubekayo kangangeminyaka emithathu. Ukuguguleka komphezulu kungaphantsi kwe-0.01mm. Xa kuthelekiswa neziseko zesinyithi, umjikelo wokutshintsha wongezwa kabini, nto leyo enciphisa ngokufanelekileyo iindleko zokugcina izixhobo.

Ii. Ukuphuculwa kweNkqubo: Uyilo olwenziwe ngokwezifiso luphucula ukusebenza kakuhle kwemveliso

Iziseko zegranite zanamhlanje, ngokusebenzisa ukucubungula ngokuchanekileyo kunye nezakhiwo ezintsha, ziyandisa ngakumbi ixabiso lazo lokusetyenziswa:

Ukucubungula okucwangcisiweyo okusemgangathweni ophezulu: Ngokusebenzisa iteknoloji yokulawula amanani e-linkage ye-five-axis, ubucaba besiseko bulawulwa ngaphakathi kwe-±0.5μm/m, okubonelela ngomphezulu othe tyaba kakhulu wezixhobo zokubhola kunye nokuqinisekisa ukuba impazamo yokuma kwe-drill bit ingaphantsi kwe-0.01°.

Ulwakhiwo lokufunxa uloyiko lwehoneycomb: Uyilo lwangaphakathi lwehoneycomb lwenza umngxuma ozimeleyo, lufezekisa ukuncitshiswa kwamandla okungcangcazela kwamanqanaba amaninzi, kwaye lufanelekile ngokukodwa ekucutshungulweni kwemingxunya emincinci ye-0.1mm okanye ngaphantsi.

Iitshaneli zokupholisa amanzi ezifakwe kwangaphambili: Kwizixhobo zokubhola ezinamandla aphezulu, kufakelwa inkqubo yokupholisa amanzi enetshaneli encinci eyakhelwe ngaphakathi ukulawula umahluko wobushushu kumphezulu osisiseko ngaphakathi kwe-±0.5℃, isusa ngokupheleleyo umngcipheko wokuguquka kobushushu.

Uyilo lwe-T-slot eyenzelwe wena: Isithuba kunye nokuchaneka kwe-T-slot (± 0.01mm) zenzelwe wena ngokwemodeli yomatshini wokubhola ukuze kufezekiswe ukubekwa kunye nokufakelwa kwezixhobo ngokukhawuleza, kunciphisa ixesha lokuqalisa isixhobo esinye nge-70%.

Iii. Ubungqina boShishino: Ukuphuculwa okubonakalayo kokusebenza kakuhle

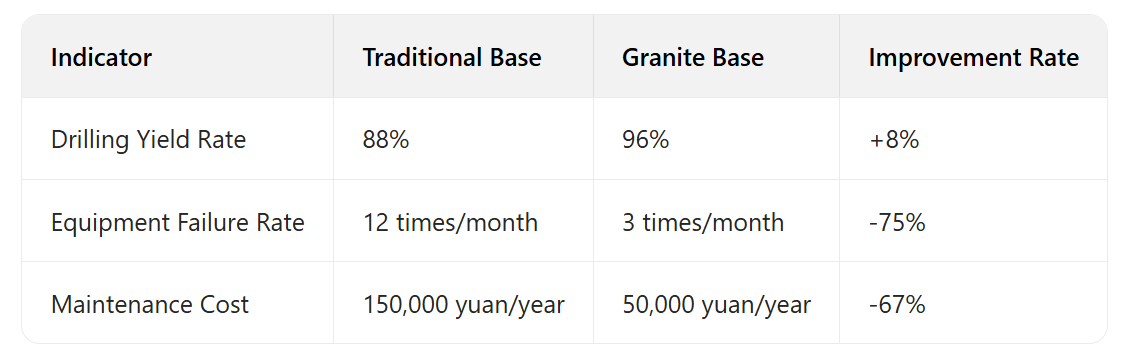

Emva kokuba umenzi othile ophambili we-PCB eqalise iziseko ze-granite, idatha yemveliso yayo iphumelele uphuculo olukhulu:

Okubaluleke ngakumbi, isiseko segranite sincede amashishini ukuba aphume kwiingxaki zobugcisa, aphumelele eku-odoleni ii-micro-holes ze-0.2mm okanye ngaphantsi, kwaye avule iimarike ezinexabiso eliphezulu.

Iv. Iingenelo eziZinzileyo: Ukhetho olufanelekileyo lokuvelisa izinto eziluhlaza

I-Granite lilitye lendalo elingenazo iikhemikhali zokwambathisa kwaye alinazo ii-VOCs ezikhutshwayo, lihlangabezana nemigangatho yokhuseleko lokusingqongileyo ye-RoHS. Ubomi bayo obude kakhulu benkonzo bunciphisa ukuphindaphindeka kokutshintshwa kwezixhobo, kunciphisa ukusetyenziswa kwezixhobo kunye nokukhutshwa kwekhabhoni. Ubalo oluthile lwe-arhente yokhuseleko lokusingqongileyo lubonisa ukuba ukusebenzisa isiseko se-granite kwisixhobo esinye sokugrumba se-PCB kunokunciphisa ukukhutshwa kwekhabhoni ngeetoni ezi-3 kulo lonke umjikelo wobomi bayo, okuhambelana nomkhwa wotshintsho oluhlaza kwishishini lokuvelisa.

Ukusuka kulawulo lokuchaneka kwinqanaba le-micron ukuya kuphuculo lweendleko zenkqubo epheleleyo, iziseko zegranite ziyayila ngokutsha imigangatho yeenkqubo zokubhola ze-PCB ngeenzuzo zazo zokusebenza ezingenakutshintshwa. Kweli xesha langoku lemfuno enkulu yeetships ze-5G kunye ne-AI, ukukhetha isiseko segranite akukokutyala nje kuphela umgangatho wemveliso kodwa kukwalinyathelo elibalulekileyo lokuthatha indawo ephezulu yetekhnoloji.

Ixesha leposi: Juni-17-2025