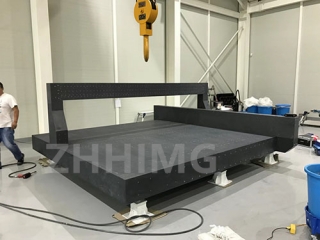

Kwindibano yocweyo yokwenziwa kwe-semiconductor, iimfuno zenkqubo yokwenziwa kwetshiphu yeemeko zokusingqongileyo kunye nokuchaneka kwezixhobo zigqithisile, kwaye nakuphi na ukutenxa okuncinci kunokukhokelela ekwehleni okukhulu kwemveliso yetshiphu. I-platform ye-XYZT yokuchaneka kwe-gantry yokunyakaza ixhomekeke kumacandelo e-granite ukusebenzisana namanye amacandelo eqonga ukwakha isiseko esiqinileyo sokufezekisa ukuchaneka kwe-nanoscale.

Iimpawu ezigqwesileyo zokuthintela ukungcangcazela

Kwiworkshop yokwenziwa kwesemiconductor, ukusebenza kwezixhobo zeperipheral kunye nabasebenzi abahambahambayo kunokubangela ukungcangcazela. Ulwakhiwo lwangaphakathi lwamacandelo e-granite luxinene kwaye lufana, kunye neempawu zendalo zokudambisa eziphezulu, njenge-vibration esebenzayo "umqobo". Xa i-vibration yangaphandle idluliselwa kwi-platform ye-XYZT, inxalenye ye-granite inokunciphisa ngokufanelekileyo ngaphezu kwe-80% yamandla okunyakaza kunye nokunciphisa ukuphazanyiswa kwe-vibration kwi-platform motion . Ngelo xesha, iqonga lixhotyiswe nge-high-precision air float guide system, esebenza ngokubambisana namacandelo e-granite. Isalathiso se-air float sisebenzisa ifilimu yegesi ezinzileyo eyenziwe yigesi ephezulu yoxinzelelo ukuze iqonde intshukumo yokunqunyanyiswa okungenakuthintelwa kweendawo ezihambayo zeqonga kunye nokunciphisa ukungcangcazela okuncinci okubangelwa ukubetha koomatshini. Ngokudibeneyo, ezi zimbini ziqinisekisa ukuba ukuchaneka kokubekwa kweqonga kuhlala kugcinwa kwinqanaba le-nanometer kwiinkqubo eziphambili ezifana ne-chip lithography kunye ne-etching, kwaye ugweme ukuphambuka kweepatheni zeesekethe ze-chip ezibangelwa yi-vibration.

Uzinzo oluhle kakhulu lwe-thermal

Ukuguquguquka kweqondo lokushisa kunye nokufuma kwi-workshop kunempembelelo enkulu ekuchanekeni kwezixhobo zokuvelisa i-chip. I-coefficient yokwandisa i-thermal ye-granite iphantsi kakhulu, ngokuqhelekileyo kwi-5-7 × 10⁻⁶/℃, ubukhulu buphantse bungatshintshi xa ubushushu buguquka. Nangona umahluko weqondo lokushisa phakathi kwemini nobusuku kwindawo yokusebenzela okanye ukuveliswa kobushushu bezixhobo kubangela ukuba ubushushu be-ambient buguquguquke, amacandelo e-granite angakwazi ukuhlala ezinzile ukuthintela ukuguqulwa kweqonga ngenxa yokwandiswa kwe-thermal kunye nokunciphisa. Kwangaxeshanye, inkqubo yokulawula ubushushu obukrelekrele exhotyiswe iqonga esweni ubushushu ambient ngexesha lokwenyani, ulungelelanisa ngokuzenzekelayo umoya umoya kunye nezixhobo zokuchitha ubushushu, kwaye igcina ubushushu workshop kwi-20 ° C ± 1 ° C. Idityaniswe iingenelo uzinzo ubushushu begranite, ukuqinisekisa ukuba iqonga ekusebenzeni ixesha elide, ukuchaneka kwentshukumo yemveliso naxinometer rhoqo ukuqinisekisa ukuchaneka kwemveliso ye-axinometer nganye, ukuqinisekisa ukuchaneka komgangatho we-axinometer nganye. Ubungakanani bepateni ye-chip lithography ichanekile, ubunzulu be-etching bufanayo.

Ukuhlangabezana neemfuno zemo engqongileyo ecocekileyo

Ivenkile yokuvelisa i-semiconductor kufuneka igcine iqondo eliphezulu lokucoceka ukukhusela amasuntswana othuli ekungcoliseni itshiphu. Izinto zeGranite ngokwazo azivelisi uthuli, kwaye umphezulu ulula, akulula ukufunxa uthuli. Iqonga lilonke lithatha idizayini yesakhiwo esivaliweyo ngokupheleleyo okanye esivaliweyo sokunciphisa ukungena kothuli lwangaphandle. Inkqubo yangaphakathi yokujikeleza komoya idityaniswe nenkqubo yococeko lomoya ecocekileyo yocweyo ukuze kuqinisekiswe ukuba ukucoceka komoya kwangaphakathi kufikelela kwinqanaba elifunekayo ngokwenza itshiphu. Kulo mmandla ococekileyo, amacandelo e-granite awayi kuchaphazela ukusebenza ngenxa yokukhukuliseka kothuli, kwaye amacandelo aphambili afana ne-high-precision sensors kunye neemotor zeqonga nazo zinokusebenza ngokuzinzileyo, zibonelela ngokuqhubekayo kwaye zithembekileyo isiqinisekiso sokuchaneka kwe-nanoscale yokwenziwa kwe-chip, kunye nokunceda imboni ye-semiconductor ukuba ihambe ukuya kwinqanaba eliphezulu lenkqubo.

Ixesha lokuposa: Apr-14-2025