Kwishishini leemoto, ukuchaneka kobukhulu bezinto ezisetyenziswayo kuchaphazela ngokuthe ngqo ukusebenza, ukhuseleko kunye nokuthembeka kwesithuthi siphela. Ukusuka kwizinto eziphambili zenjini ukuya kwiindawo zokuhambisa ngokuchanekileyo, yonke into engalunganga inokubangela ukusabela kwetsheyini, okukhokelela kwingxolo engaqhelekanga, ukusetyenziswa kwepetroli okwandisiweyo kunye neengozi zokhuseleko kwisithuthi. Izixhobo zokulinganisa igranite, ezineempawu zazo zomzimba ezizodwa kunye neenzuzo zobugcisa, ziye zaba zizixhobo eziphambili zokuqinisekisa ukuchaneka kobukhulu obuphezulu kwinkqubo yokwenziwa kwezinto ezisetyenziswayo, zibeka isiseko esiqinileyo sophuhliso olusemgangathweni ophezulu kwishishini leemoto.

Iingenelo zendalo zezixhobo zokulinganisa i-granite: isiseko sozinzo kunye nokuchaneka

I-Granite luhlobo lwelitye lendalo elenziwe ngeenkqubo zejoloji zexesha elide. Iikristale zayo zangaphakathi zeminerali zixinene kwaye isakhiwo sixinene kwaye siyafana, nto leyo eyenza ukuba isebenze kakuhle. Okokuqala, i-granite inomlinganiselo ophantsi kakhulu wokwandiswa kobushushu, oqhele ukuba phakathi kwe-5 ukuya kwi-7×10⁻⁶/℃. Olu phawu lwenza ukuba ingachaphazeleki phantse lutshintsho lobushushu. Kwiiworkshop zokwenza izixhobo zeemoto, ubushushu obuveliswa kukusebenza kwezixhobo kunye nokuguquguquka kobushushu bendalo buqhelekile. Izixhobo zokulinganisa ezenziwe ngezinto eziqhelekileyo zinokubangela iimpazamo zobukhulu ngenxa yokwanda kobushushu kunye nokucutheka, okuchaphazela ukuchaneka kokulinganisa. Izixhobo zokulinganisa i-granite zinokugcina uzinzo lobukhulu xa ubushushu butshintsha, ziqinisekisa ukuthembeka kwedatha yokulinganisa kwaye zibonelela ngemigangatho echanekileyo yesalathiso yokucubungula izinto.

Okwesibini, ubulukhuni obuphezulu kunye nokumelana nokuguguleka kwegranite yenye inzuzo enkulu yayo. Igranite enobulukhuni beMohs obuyi-6 ukuya kwi-7 ayiguguleki ngexesha lokulinganisa rhoqo. Ukuveliswa kwezixhobo zeemoto kudla ngokubandakanya umsebenzi omkhulu wokulinganisa ophindaphindwayo. Izixhobo zokulinganisa igranite zinokugcina indawo yokulinganisa echanekileyo kakhulu kulo lonke ixesha lokusetyenziswa ixesha elide, zinciphise ukuphambuka kokulinganisa okubangelwa kukuguguleka kwezixhobo, zandise ubomi benkonzo kwaye zinciphise iindleko zokutshintsha izixhobo kumashishini ngaxeshanye. Ukongeza, igranite ikwanokusebenza kakuhle kokuguguleka kokuguguleka, okunokufunxa ngempumelelo ukuguguleka okubangelwa kukusebenza kwezixhobo zoomatshini kunye nokuthuthwa kwezinto kwindawo yokusebenzela, kubonelela ngendawo ezinzileyo yenkqubo yokulinganisa, kuthintelwe ukuphazamiseka kokuguguleka kwiziphumo zokulinganisa, kwaye kuqinisekiswe ukuchaneka kokuhlolwa kobukhulu.

Izicelo eziphambili zezixhobo zokulinganisa i-granite ekuvelisweni kwezixhobo zeemoto

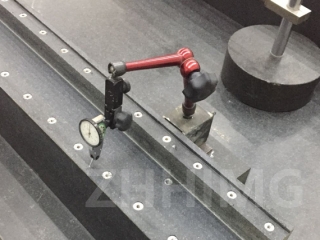

Kwinkqubo yokwenziwa kweenjini, izixhobo zokulinganisa igranite zidlala indima ebalulekileyo. Ukuchaneka kobukhulu bezinto eziphambili ezifana nebhloko yenjini kunye nentloko yesilinda kuchaphazela ngokuthe ngqo ukusebenza kakuhle kokutsha kunye nokukhupha amandla. Iqonga legranite, elinobucaba obuphezulu kakhulu (ukuya kuthi ga kwi-±0.005mm/m), libonelela ngereferensi echanekileyo yokuchongwa kobucaba bebhloko yesilinda kwaye liqinisekisa ukutywinwa komphezulu ngamnye odibeneyo. Iibhloko zegranite gauge, izitendi zesalathisi sokudayela kunye nezinye izixhobo zinokulinganisa ngokuchanekileyo iiparameter eziphambili ezifana nobubanzi bomngxuma wephini yepiston kunye nobukhulu bejenali ye-crankshaft, zilawula ngokungqongqo impazamo kwinqanaba le-micrometer ukuqinisekisa ukuchaneka kokuhlanganiswa kunye nokuzinza kokusebenza kwenjini.

Izixhobo zokulinganisa igranite nazo zibalulekile ekuvelisweni kwezinto zenkqubo yokudlulisa iimoto. Ukuchaneka kweprofayili yamazinyo kwiigiya zokudlulisa, ukuqina kweendawo zeshaft kunye nezinye izalathisi zinxulumene ngokuthe ngqo nokuguda kokutshintsha kwegiya kunye nokusebenza kakuhle kokudlulisa kwesithuthi. Isixhobo sokulinganisa uhlobo lwerail yesikhokelo segranite sinokukhokela iprobe yokulinganisa ukuze iskena ngokuchanekileyo iprofayili yamazinyo egiya ngokuthe tye kakhulu kwaye kuzinze, kwaye ukuchaneka kokufumanisa iimpazamo kunokufikelela ku-±0.002mm. Iibhokisi zesikwere zegranite zisetyenziselwa ukubona ukuthe nkqo kunye nokuhambelana kweendawo zeshaft, ukuqinisekisa ukuchaneka kobudlelwane bokuhlanganisa phakathi kwecandelo ngalinye kunye nokuphucula ukuthembeka kwenkqubo yokudlulisa.

Ukongeza, ngexesha lenkqubo yokwenziwa kwezinto ze-chassis zeemoto, iimfuno zokuchaneka kobukhulu bezinto ezifana nenkqubo yokumiswa kunye nenkqubo yokuqhuba zingqongqo ngokulinganayo. Izixhobo zokulinganisa i-granite zilinganisa kwaye zilawula ngokuchanekileyo ubukhulu obufana nobubanzi bomngxuma, ububanzi be-slot, kunye nobude bezinto, ukuqinisekisa ukutshintshiselana kunye nokuchaneka kokuhlanganiswa kwenxalenye nganye ye-chassis, kunye nokubonelela ngesiqinisekiso sozinzo kunye nokuphathwa kokusebenza kwesithuthi.

Khuthaza ukuqhubela phambili ukwenziwa kweemoto ukuya kumgangatho ophezulu

Njengoko ishishini leemoto lisiya kubukrelekrele kunye nokufakelwa kombane, iimfuno zokuchaneka kwezixhobo ziya ziba nzima ngakumbi. Izixhobo zokulinganisa i-granite, ngokusebenza kwazo okuzinzileyo kunye nokuchaneka okugqwesileyo, ziye zaba sisixhobo esiphambili kumashishini eemoto ukuphucula umgangatho wemveliso kunye nokuphucula ukhuphiswano lwemarike. Ngokusebenzisa izixhobo zokulinganisa i-granite, amashishini anokulawula ngokungqongqo ubukhulu bezixhobo, anciphise izinga leenkunkuma, anciphise umjikelo wemveliso kwaye aphucule ukusebenza kakuhle kwemveliso.

Kwixesha elizayo, ngokuqhubela phambili okuqhubekayo kwetekhnoloji yokwenziwa kweemoto, izixhobo zokulinganisa igranite nazo ziya kudityaniswa ngokunzulu netekhnoloji yokulinganisa yedijithali kunye neenkqubo zokufumanisa ezenzekelayo, nto leyo ephucula ngakumbi inqanaba lobukrelekrele kunye nokuchaneka kokulinganisa. Ukusuka kwizithuthi zepetroli zemveli ukuya kwizithuthi zamandla amatsha, izixhobo zokulinganisa igranite ziya kuqhubeka nokukhusela ukwenziwa ngokuchanekileyo kwezixhobo zeemoto, zikhuthaza ishishini leemoto ukuba lihambele kuphuhliso olukumgangatho ophezulu.

Ixesha leposi: Meyi-08-2025