Izixhobo zegranite mechanical zisetyenziswa kakhulu kushishino lwanamhlanje ngenxa yobunzima obungaqhelekanga bezinto zendalo, amandla okucinezelwa, kunye nokumelana nokugqwala. Ngeendlela zokwenza ngokuchanekileyo, igranite iba yindlela efanelekileyo endaweni yesinyithi kwiintlobo ngeentlobo zezicelo ze-mechanical, chemical, kunye ne-structure.

Eli nqaku lichaza inkqubo yokuvelisa, iimpawu eziphambili, kunye neemeko eziqhelekileyo zokusetyenziswa kwezinto zegranite kumatshini oshishino.

Kutheni Ukhetha iGranite yeeComponents zeMechanical?

I-Granite lilitye elivela ngokwemvelo eliyi-igneous eliqulunqwe ngokuyintloko:

-

I-Pyroxene

-

I-Plagioclase feldspar

-

I-olivine encinci kunye ne-biotite mica

-

I-trace magnetite

Emva kokwaluphala kwendalo, igranite ibonakalisa ubume obufanayo, ukuvuleka okuphantsi, kunye nokuqina okuphezulu kwesakhiwo—okuyenza ilungele ukusetyenziswa ngokuchanekileyo kwimizi-mveliso.

Iingenelo eziphambili zeenxalenye zeGranite Mechanical

1. Ubunzima obuphezulu kunye nokumelana nokunxiba

I-Granite inobunzima be-Mohs obungaphezulu kwe-6, nto leyo eyenza ukuba ingabi nakumelana nokuguguleka. Ilungele iindawo ezinomthwalo omkhulu, ezihamba ngesantya esiphezulu ezifana nezixhobo zoomatshini, iigiya, kunye nezikhokelo ezithe tye.

2. Ukumelana nokugqwala okugqwesileyo

Ngokungafaniyo nezinto zesinyithi, igranite ayimelani ngokwemvelo nee-asidi, ii-alkalis, kunye neetyuwa. Ifanelekile kwizixhobo zokucubungula iikhemikhali, oomatshini baselwandle, kunye neendawo ezinobungozi.

3. Amandla Aqinileyo Okucinezela

Ulwakhiwo lweGranite luyivumela ukuba imelane nemithwalo ephezulu yoomatshini ngaphandle kokuguquka, nto leyo eyenza ukuba ifaneleke kwiindawo ezithwala uxinzelelo ezifana neenqanawa, iikholamu zenkxaso, kunye neefreyimu zomthwalo.

4. Uzinzo olunemilinganiselo

Ngomlinganiselo wokwandiswa kobushushu obuphantsi, igranite igcina imo yayo phantsi kotshintsho olukhulu lobushushu. Isetyenziswa rhoqo kwiindawo ezichanekileyo nezishushu kakhulu.

5. Ubuhle kunye nokusebenza kakuhle

Ngenxa yemibala yayo etyebileyo kunye nomphezulu ocwebezelayo, igranite ikwasetyenziswa kwimishini yokwakha, kwizikhumbuzo, nakwiindawo zoomatshini eziqingqiweyo, idibanisa ukusebenza kunye nomtsalane obonakalayo.

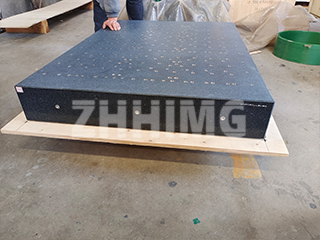

Inkqubo yokuVelisa iGranite Mechanical Component

1. Ukukhetha Izinto

Kukhethwa iibhloko zegranite kuphela ezingenazimfanta, iinkozo ezifanayo, kunye noxinzelelo oluncinci lwangaphakathi. Igranite emnyama idla ngokuthandwa ngenxa yeempawu zayo eziphezulu zobushushu kunye nolwakhiwo.

2. Ukusika

I-granite isikwa ibe ziibhloko ezirhabaxa zobukhulu obufunekayo kusetyenziswa iisarha zentambo yedayimani okanye ii-blade cutters, kuxhomekeke kwi-geometry yenxalenye.

3. Ukubumba kunye ne-CNC Machining

Iibhloko ezisikiweyo ngokungekho mthethweni zicwangciswa zibe ziimo zokugqibela kusetyenziswa oomatshini be-CNC, ii-grinder, okanye ukupolisha ngesandla, kuxhomekeke kwiimfuno zokunyamezela. Izinto ezifana neziseko zoomatshini okanye izindlu zegiya zifuna ukuchaneka kwinqanaba le-micron.

4. Unyango Lomphezulu

Imiphezulu iyagaywa kakuhle, icoliwe, kwaye ipolishwe ukuze ihlangabezane neemfuno zobugcisa. Kwiindawo zoomatshini, oku kuqinisekisa ukulingana okuqinileyo kunye nokulungelelaniswa ngokuchanekileyo.

5. Uhlolo lokugqibela

Icandelo ngalinye liyahlolwa ngobungakanani, lihlolwe umphezulu, kwaye livavanywe ulwakhiwo ukuqinisekisa ukuthotyelwa kwemigangatho yamazwe ngamazwe kunye neenkcukacha ezenziwe ngokwezifiso.

Iindawo eziphambili zokusetyenziswa

1. Ukuveliswa kwezixhobo zoomatshini

I-granite isetyenziswa kakhulu ukuvelisa iziseko zoomatshini be-CNC, ukulungelelanisa iibhedi zoomatshini zokulinganisa, kunye nee-spindle mounts, ngenxa yokuzinza kwayo kunye nokusebenza kwayo okudambisa ukungcangcazela.

2. Oomatshini boBunjineli

Iigiya zegranite, iishafts, kunye nezinye izinto ezingagugiyo zilungele izixhobo zokwakha nezokwemba ezisebenza nzima.

3. Izixhobo Zokucubungula Iikhemikhali

Iinqanawa zegranite, iimpompo, okanye izixhobo zokuxhasa imibhobho zibonelela ngokumelana nokugqwala okuphezulu kwiindawo ezinoburhalarhume beekhemikhali.

4. Izinto zokwakha nezokuhlobisa

Izixhobo zegranite mechanical nazo zisetyenziswa kwiindawo zokwakha ezikumgangatho ophezulu, zidibanisa umsebenzi wobunjineli kunye noyilo oluhle, njengakwiikholamu ezenziwe ngokwezifiso, iikheyiji zoomatshini bobugcisa, okanye imifanekiso eqingqiweyo yomgangatho wemizi-mveliso.

Isiphelo

Izixhobo zoomatshini begranite zibonelela ngomxube onamandla wokuqina, ukuchaneka, kunye nokumelana nokugqwala, nto leyo eyenza ukuba zibe lukhetho oluhle kakhulu kumashishini afuna ukusebenza okuthembekileyo phantsi kweemeko ezinzima. Ngokuhambela phambili kwi-CNC granite machining kunye noyilo lwemodyuli, igranite iba yindlela efanelekileyo nezinzileyo kuneenkqubo zoomatshini zemveli ezisekwe kwisinyithi.

Ixesha lokuthumela: Agasti-01-2025