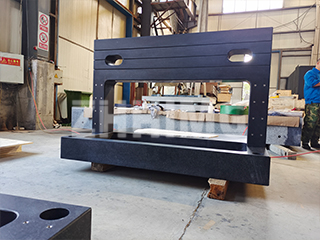

Ipleyiti yomphezulu wegranite, ekwaziwa njengeqonga lokuhlola igranite, sisiseko sereferensi esichanekileyo esisetyenziswa kakhulu kwimveliso yemizi-mveliso, kwiilebhu, nakwiindawo zokulinganisa. Yenziwe ngegranite yendalo ekumgangatho ophezulu, inika ukuchaneka okuphezulu, uzinzo olulinganayo, kunye nokumelana nokugqwala, okwenza ukuba ilungele uluhlu olubanzi lwezicelo zokulinganisa kunye nokulinganisa.

Ukwakhiwa kwezinto kunye neempawu ezibonakalayo

I-granite esetyenziselwa iiplatifomu zokuchaneka idla ngokuqulatha:

-

I-Pyroxene

-

I-Plagioclase

-

Inani elincinci le-olivine

-

I-mica ye-biotite

-

I-trace magnetite

Ezi zinto zimbiwayo zinika i-granite umbala omnyama, ulwakhiwo oluxineneyo, kunye nobume obufanayo. Emva kokwaluphala kwendalo, ilitye lifikelela:

-

Amandla aphezulu okucinezela

-

Ubulukhuni obuhle kakhulu

-

Uzinzo oluphezulu phantsi kwemithwalo enzima

Oku kuqinisekisa ukuba ipleyiti yomphezulu igcina ithambile kwaye ichanekile, nokuba kukwiindawo zoshishino ezifuna amandla.

Iindlela Zokusetyenziswa Kwanamhlanje: Ukuthamba Ngaphezulu Kwamachaphaza Okunxibelelanayo

Ngaphambili, abasebenzisi babesoloko begxininisa inani leendawo zokunxibelelana xa bevavanya iipleyiti zomphezulu wegranite. Nangona kunjalo, ngenxa yobukhulu obukhulayo kunye nobunzima bezinto zokusebenza, eli shishini liye latshintshela ekubekeni phambili ubucaba bomphezulu endaweni yoko.

Namhlanje, abavelisi kunye nabasebenzisi bagxila ekuqinisekiseni ukunyamezelana kokutyibilika ngokubanzi endaweni yokwandisa iindawo zokunxibelelana. Le ndlela ibonelela:

-

Imveliso engabizi kakhulu

-

Ukuchaneka okwaneleyo kwiimfuno ezininzi zoshishino

-

Ukuziqhelanisa nezinto zokusebenza ezinkulu kunye nezixhobo

Kutheni Ukhetha iGranite kwiZicelo zoMlinganiselo?

1. Uzinzo olunemilinganiselo

I-granite idlula kwiminyaka eyizigidi yokwaluphala kwendalo, isusa uxinzelelo lwangaphakathi. Isiphumo sisixhobo esizinzileyo, esingaguqukiyo esifanelekileyo ukusetyenziswa ixesha elide kwiindawo ezichanekileyo.

2. Ukumelana neekhemikhali kunye nemagnethi

I-granite ayixhathisi kwii-asidi, ii-alkali, ukugqwala, kunye nokuphazamiseka kwemagnethi, okwenza ukuba ifaneleke kwiindawo zokugcina iikhemikhali, amagumbi okucoca, kunye nemveliso yobuchwepheshe obuphezulu.

3. Ukwanda okuphantsi kobushushu

Ngomlinganiselo wokwandiswa kobushushu phakathi kwe-4.7 × 10⁻⁶ ukuya kwi-9.0 × 10⁻⁶ intshi/intshi, iindawo zegranite azichaphazeleki kakhulu kutshintsho lobushushu, nto leyo eqinisekisa ukufundwa okuchanekileyo kwiimeko eziguquguqukayo.

4. Ayinamanzi kwaye ayinamhlwa

Ngokungafaniyo nezinye iindlela zesinyithi, i-granite ayithintelwa kukufuma kwaye ayisoze igqwale, nto leyo eqinisekisa ukuba ayigcinwa ixesha elide kwaye ayisebenzi ixesha elide.

5. Ukuqina Okugqwesileyo kunye nokumelana nokunxiba

Njengenye yezona zinto zokwakha zinzima, i-granite inika ukumelana okumangalisayo nokukrweleka, nokuba isetyenziswa rhoqo.

6. Ukugqitywa komphezulu ogudileyo

Umphezulu ungacolwa kakuhle uze upholishwe, unike ukugqitywa okufana nesipili okuncinci okuqinisekisa ukudibana kakuhle neendawo ezilinganisiweyo.

7. Ukunyamezelana Neempembelelo

Ukuba umphezulu ukrwelwe okanye ubethekile, i-granite idla ngokuvelisa imingxunya emincinci endaweni yee-burrs okanye imiphetho ephakanyisiweyo—ukuphepha ukugqwetheka kwiimilinganiselo ezibalulekileyo.

Ezinye iingenelo zeePleti zoHlolo lweGranite

-

Ayinamagnethi kwaye ayimelani ne-static

-

Kulula ukuyicoca nokuyigcina ikwimeko entle

-

Inobuhlobo nokusingqongileyo kwaye yenziwe ngokwendalo

-

Ifumaneka kwiindidi ezahlukeneyo kunye nobukhulu

Isiphelo

Ipleyiti yomphezulu wegranite isaqhubeka nokuba sisixhobo esisisiseko kumashishini anamhlanje okuchaneka. Ngenxa yokuchaneka kwayo okulinganayo, ukuzinza kwexesha elide, kunye nokuchasana nezinto ezingqongileyo, ixhasa usetyenziso oluqala kwi-CNC machining ukuya kulawulo lomgangatho kwi-elektroniki, kwi-aerospace, nakwizixhobo.

Njengoko ubukhulu bezinto zokusebenza kunye nobunzima bokuhlola bukhula, iipleyiti zomphezulu wegranite zihlala zisisombululo esithembekileyo nesingabizi kakhulu sokugcina imigangatho ephezulu yokulinganisa.

Ixesha lokuthumela: Agasti-01-2025