Iinkqubo zokulinganisa ngokuchanekileyo zenza umqolo wolawulo lomgangatho wokwenziwa kwanamhlanje. Njengoko ukunyamezelana kuqina kwaye ubunzima bezinto bukhula, ukuchaneka nokuzinza kwezixhobo zokulinganisa kuye kwaba zizinto ezibalulekileyo zokukhuphisana kubavelisi kwihlabathi liphela. Embindini wezi nkqubo kukho iipleyiti zomphezulu wegranite kunye nezakhiwo ezisekwe kwigranite, ezibonelela ngejometri ezizinzileyo zokujonga ubukhulu kunye nokulinganisa okudibeneyo.

EYurophu naseMntla Melika, imfuno yabavelisi beepleyiti zegranite ezisebenza kakuhle ikhule ngokuthe chu kunye nokwandiswa kwemveliso ye-semiconductor, imveliso yeenqwelo moya, kunye nokuziqhelanisa okuphucukileyo. Eli nqaku lihlola indima yabavelisi beepleyiti zegranite ezisebenza kakuhle kwi-ecosystem ye-precision metrology, liphonononga usetyenziso oluphambili lwegranite kwiimashini zokulinganisa ezilungelelanisiweyo (ii-CMM), kwaye lichaza indlela igranite exhasa ngayo ukusebenza kweenkqubo zanamhlanje ze-precision metrology.

Abavelisi bePlate yeGranite Surface: Ulindelo lweMarike kunye neemfuno zobugcisa

Iipleyiti zomphezulu wegranite zizinto ezisisiseko kwi-metrology enobukhulu. Zibonelela ngemigangatho yesalathiso esithe tyaba nesizinzileyo sokuhlolwa, ukulinganiswa, kunye nemisebenzi yokuhlanganisa. Nangona kunjalo, ayingabo bonke abavelisi beepleyiti zomphezulu wegranite abanikezela ngenqanaba elifanayo lokusebenza okanye ukuhambelana.

Abavelisi abakumgangatho ophezulu bagxila ekukhetheni izinto njengento ebangela umahluko omkhulu. I-granite emnyama yeprimiyamu enesakhiwo esifanayo seenkozo kunye noxinano oluphezulu inika uzinzo oluphezulu kunye nokumelana nokuguguleka. Izinto ezingaphantsi zinokuhlangabezana neemfuno zokuqala zokusitha kodwa zinokubonisa ukuguguleka kwexesha elide okanye ukuguguleka kwendawo phantsi kokusetyenziswa rhoqo.

Amandla okuvelisa nawo abaluleke kakhulu. Ukusila ngokuchanekileyo kunye nokulepha kufuneka kwenziwe kwiindawo ezilawulwa bubushushu ukuze kufezekiswe ukuthamba kunye nokuthe tye kwinqanaba le-micron. Abavelisi begranite surface plate abaziwayo bakwagcina iinkqubo zokuhlola eziqinileyo, kubandakanya i-laser interferometry kunye nezixhobo zereferensi ezilinganisiweyo, ukuqinisekisa ukuthotyelwa kwemigangatho yamazwe ngamazwe.

Kubathengi baseYurophu naseMntla Melika, ukulandeleka, ukugcinwa kwamaxwebhu, kunye nomgangatho ohambelanayo kubalulekile. Iipleyiti zomphezulu zihlala zidityaniswa kwiinkqubo zomgangatho eziqinisekisiweyo, nto leyo eyenza ukuchaneka kwexesha elide kunye nokuzinza kohlengahlengiso kube yimigangatho ephambili yovavanyo xa ukhetha umthengisi.

Ukusetyenziswa kweGranite kwiimashini zokulinganisa ezidibeneyo (iiCMM)

Oomatshini bokulinganisa abalungelelanisiweyo bamele enye yezona zicelo zinzima kakhulu kwizixhobo zegranite ezichanekileyo. Kwi-CMMs, igranite ayipheleli nje kwiipleyiti zomphezulu kuphela, kodwa isetyenziswa kakhulu njengezinto zokwakha kumatshini wonke.

I-Granite njengeSakhiwo seSiseko seCMM

Isiseko se-CMM kufuneka sinike ukuqina okungaqhelekanga kunye nokuzinza kobushushu ukuxhasa umlinganiselo ochanekileyo wemilinganiselo emithathu. Iziseko zegranite zibonelela ngokwandiswa kobushushu okuphantsi kunye nokunciphisa ukungcangcazela okugqwesileyo, okunciphisa ukungaqiniseki komlinganiselo okubangelwa lutshintsho lokusingqongileyo okanye ukuphazamiseka kwangaphandle.

Ngokungafaniyo nezakhiwo zesinyithi ezitshisiweyo okanye ezenziwe ngentsimbi, iziseko zegranite azinaxinzelelo olushiyekileyo, nto leyo ebavumela ukuba bagcine ukuthembeka kwejometri ixesha elide. Oku kwenza igranite ibe yinto efanelekileyo kuzo zombini uyilo lwe-CMM yohlobo lwebhulorho kunye nolwe-gantry.

Iibhulorho zeGranite kunye neeKholamu

Igranite ikwasetyenziselwa iibhulorho, iikholamu, kunye nezakhiwo zesikhokelo ngaphakathi kwi-CMMs. Ezi zinto kufuneka zigcine ulungelelwaniso oluchanekileyo phantsi kwentshukumo eguquguqukayo ngelixa zixhasa ubunzima obuhambayo njengeenkqubo zokuphonononga kunye neekhareji. Iimpawu zokudambisa zegranite ziphucula uzinzo lwenkqubo kwaye zinciphise ixesha lokuzinza ngexesha lemijikelo yokulinganisa.

Ukudibanisa neeBearings zoMoya kunye neeLinear Drives

Ii-CMM ezininzi ezikumgangatho ophezulu zisebenzisa ii-air bearing kunye nee-linear motors ukuze zifikelele kwintshukumo egudileyo nephantsi yokungqubana. Imiphezulu yegranite ibonelela ngeendawo zokubhekisa ezilungileyo kwiinkqubo zokuthwala umoya, ixhasa ukuziphatha kwefilimu yomoya rhoqo kunye nokuchaneka kokubekwa okuphindaphindwayo. Olu dibaniso luphucula ngakumbi ukusebenza ngokubanzi kweenkqubo ze-metrology echanekileyo.

I-Granite kwiiNkqubo zeMetrology eziBalaseleyo zanamhlanje

Ngaphandle kweCMM zemveli, igranite idlala indima ephambili kuluhlu olubanzi lweenkqubo zemetrology ezichanekileyo. Amaqonga okulinganisa okubonakalayo, useto lwe-laser interferometer, kunye noomatshini bokulinganisa iifom zonke zixhomekeke kwiziseko zesakhiwo ezizinzileyo ukuze zifumane iziphumo ezithembekileyo.

Iipleyiti zomphezulu wegranite zihlala zisetyenziswa njengeqonga lesiseko lee-optical comparators, iinkqubo zokulinganisa umbono, kunye nezixhobo ze-hybrid metrology. Iimpawu zazo zokudambisa ukungcangcazela zinceda ukwahlula iinkqubo zokulinganisa ezinobuthathaka kwiingxaki ezingqongileyo kwiindawo zemveliso.

Kwimigca yokuhlola ezenzekelayo, izakhiwo ezisekwe kwigranite zixhasa izitishi zokulinganisa ezingaphakathi ezisebenza ngokuqhubekekayo. Uzinzo lwexesha elide lwegranite lunciphisa isidingo sokulungiswa kwakhona rhoqo, luphucula ixesha lokusebenza kwaye lunciphise iindleko zizonke zobunini.

Iindlela Zoshishino Eziqhuba Imfuno Yezisombululo ZeMetrology Ezisekelwe KwiGranite

Iindlela ezahlukeneyo zoshishino zinegalelo ekwandeni kwemfuno yeepleyiti zomphezulu wegranite kunye nezixhobo zemetrology ezisekelwe kwigranite. Ukuveliswa kwee-semiconductor kuyaqhubeka nokunyusa iimfuno zokulinganisa kwiindidi ze-sub-micron kunye ne-nanometer, okwandisa ukuxhomekeka kwizakhiwo zoomatshini ezizinzileyo kakhulu.

Kwangaxeshanye, amashishini eenqwelo-moya kunye neemoto asebenzisa ijometri ezintsonkothileyo kunye nokunyamezelana okuqinileyo, okufuna amandla okuhlola aphambili. Iinkqubo zemetroloji echanekileyo ezakhiwe kwiziseko zegranite zibonelela ngozinzo olufunekayo ukuhlangabezana nale mingeni.

Ukwenziwa kwezinto ngokuzenzekelayo kunye nokuveliswa kwedijithali kuyayiphucula ngakumbi le mfuno. Njengoko iinkqubo zokulinganisa zidityaniswa ngqo kwimigca yemveliso, uzinzo lwesakhiwo kunye nokuqina kokusingqongileyo kuba zizinto ezibalulekileyo ekufuneka ziqwalaselwe kuyilo.

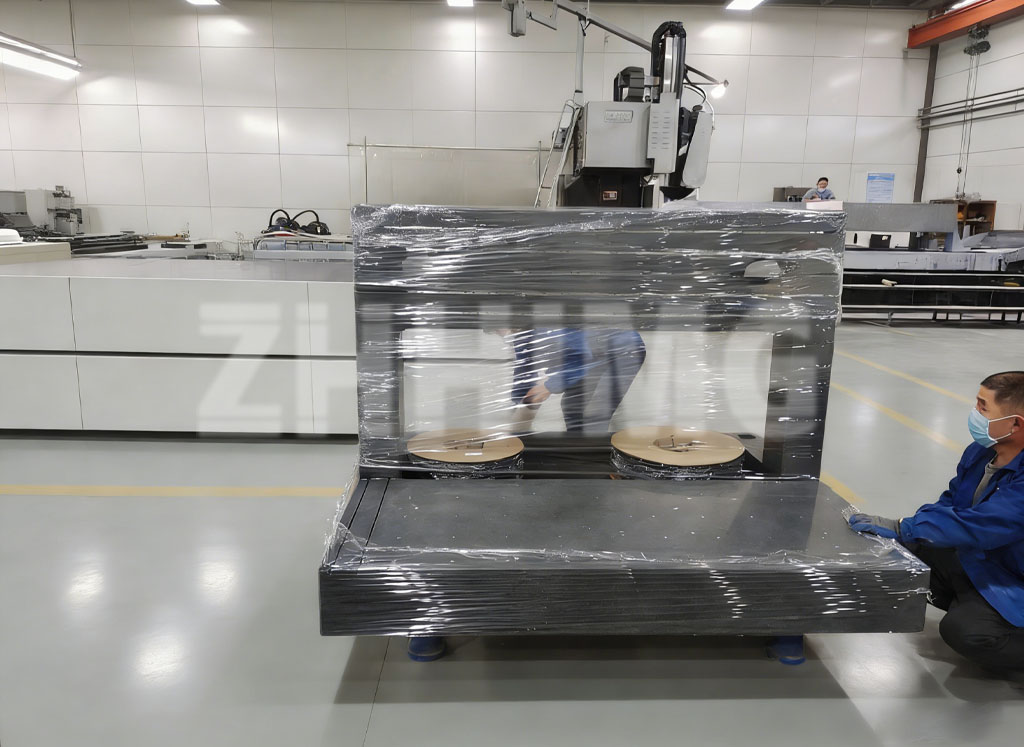

Amandla e-ZHHIMG njengoMvelisi weGranite echanekileyo

I-ZHHIMG ngumvelisi onamava weizinto zegranite ezichanekileyoukukhonza abathengi behlabathi jikelele kwi-metrology kunye nemveliso ephucukileyo. Ngokudibanisa izixhobo zegranite zeprimiyamu kunye netekhnoloji yokugaya ngokuchanekileyo kunye nokuhlola okuphucukileyo, i-ZHHIMG inika iipleyiti zomphezulu wegranite kunye nezakhiwo zeCMM ezihlangabezana nemigangatho yokuchaneka engqongqo yamazwe ngamazwe.

Izakhono zenkampani ziquka iipleyiti zomphezulu wegranite ezisemgangathweni nezenziwe ngokwezifiso, iziseko zegranite zeCMMs, izakhiwo zebhulorho kunye neegantry, kunye nezisombululo zegranite ezisetyenziswa ngokukodwa kwiinkqubo zemetrology echanekileyo. Icandelo ngalinye lenziwa phantsi kweemeko ezilawulwayo kwaye liqinisekiswe ngokuhlolwa komgangatho okupheleleyo.

Ngokusebenzisana ngokusondeleyo nabavelisi bezixhobo kunye neengcali ze-metrology, i-ZHHIMG ixhasa ukuhlanganiswa kwenkqubo okuthembekileyo kunye nokusebenza kwexesha elide kuluhlu olubanzi lwezicelo zokulinganisa ngokuchanekileyo.

Isiphelo

Iipleyiti zomphezulu wegranite kunye nezakhiwo ezisekwe kwigranite zihlala zizinto ezibalulekileyo kwiinkqubo zanamhlanje zokulinganisa ngokuchanekileyo. Ukususela kwiiplani zesalathiso ezisisiseko ukuya kwizakhiwo zeCMM ezipheleleyo, igranite inika uzinzo, ukufuma, kunye nokuqina okufunekayo ukuxhasa ukulinganiswa okuchanekileyo kobukhulu.

Njengoko amashishini eqhubeka ehambela phambili ukuya kulungelelwano oluphezulu kunye noomatshini abakhulu, indima yabasebenzi abanobuchuleipleyiti yomphezulu wegraniteabavelisi baya kuba baluleke ngakumbi. Ngobuchule obuzinikeleyo ekuveliseni i-granite echanekileyo, i-ZHHIMG ikwindawo entle yokuxhasa iimfuno eziguqukayo zeemarike zehlabathi ze-metrology kunye nokuhlolwa.

Ixesha leposi: Jan-21-2026