Xa kusenziwa izinto ezincinci, ezifana neentambo zeetships ze-semiconductor kunye nee-catheters ezintle zezixhobo zotyando ezingangenisi mandla, iimfuno zokuchaneka zihlala zifikelela kwinqanaba le-micrometer - elilingana nepesenti enye yobubanzi beenwele zomntu. Okwangoku, ibhloko ebonakala ngathi iqhelekile enomfanekiso we-V wegranite inokuba sisitshixo sokucubungula ngokuchanekileyo. Namhlanje, makhe sifumanise indlela esi "sixhobo selitye" esenza ngayo ukuba ukucutshungulwa kwezinto ezincinci kufezekise ukuchaneka okumangalisayo.

Kutheni ukhetha i-granite kwiibhloko ezimile okwe-V?

I-V-block sisixhobo esisetyenziselwa ukulungisa iindawo ezisilinda kwaye imile njengo "V" omkhulu. Inkalo ephawulekayo yeebhloko ezimile njengo-V zegranite ilele koku kulandelayo:

Isakhiwo esizinzileyo njengeMount Tai: I-granite inoxinano olukhulu kakhulu (i-granite emnyama ye-ZHHIMG® ifikelela kwi-3100kg/m³), kwaye iikristale zeminerali zangaphakathi zidibene ngokusondeleyo, njenge-"V" shape cast evela kwikhonkrithi eqinisiweyo, kwaye aziyi kuguquka nokuba ziphantsi koxinzelelo olukhulu.

Andikoyiki ukuphazamiseka kobushushu: Iintsimbi eziqhelekileyo ziyanda xa zishushu, kodwa i-coefficient yokwandiswa kobushushu begranite iphantsi kakhulu. Nokuba ubushushu bunyuka nge-10℃ ngexesha lokucubungula, ukuguquka kwayo kuncinci kangangokuba akunakuhoywa kwaye akuyi kubangela ukuba inxalenye "iphambuke".

Okukhona isetyenziswa kakhulu, kokukhona inganyangeki ngakumbi: Ubunzima begranite bufikelela kwi-6-7 kwisikali seMohs, esinzima nangakumbi kunentsimbi. Emva kokusetyenziswa ixesha elide, umphezulu uhlala uthambile kwaye uthe tyaba, kwaye awuyi kuvelisa iimpazamo ngenxa yokuguguleka okufana neebhloko zesinyithi ezimile okwe-V.

Amanyathelo omlingo okucubungula iindawo ezincinci ngeebhloko ezimile okwe-V zegranite

Fumana "isihlalo esizinzileyo" sale nxalenye

Okokuqala, coca ibhloko enomfanekiso we-V kakuhle: Sebenzisa i-ethanol engenamanzi ukuze usule uthuli kunye namabala eoyile kumphezulu. Ezi zinto zingcolileyo ezinobukhulu be-micron (ezincinci ngokuphindwe ka-20 kuneenwele zomntu) zinokubangela ukuba iindawo zithambe.

Lungisa ibhloko enomfanekiso ongu-V kwiqonga legranite: Njengokulungisa isitulo kumgangatho othe tyaba ukuqinisekisa ukuba asizukushukuma ngexesha lokucubungula. Iqonga legranite le-ZHHIMG® linobuthe tyaba obuphezulu kakhulu. Ngaphakathi kobude bemitha e-1, umahluko wobude awudluli kwiwaka leebhithi zobukhulu besiqingatha seenwele zomntu.

2. Yenza iindawo "zihlale zithe nkqo"

Beka iinxalenye ezincinci kwimiqolo emilo-V: Umzekelo, xa ucubungula umngxuma wesinyithi onobubanzi obuyi-3mm, yibeke ngobunono kumqolo omilo-V ongu-90°.

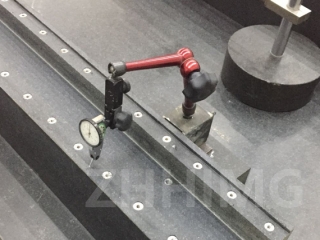

Linganisa ngesalathisi sokudayela: Esi sisixhobo esichanekileyo esikwaziyo ukulinganisa impazamo ye-0.001mm. Kufana "nokulinganisa ukuphakama" kwenxalenye ukuqinisekisa ukuba ilingana ngokupheleleyo. Ukuba imilo yenxalenye ikhethekile, iibhloko zegranite parallel (ezinempazamo yobukhulu engadluli kwi-1μm) nazo zingasetyenziselwa ukuyiphakamisa, ukugcina umgangatho womphezulu ocutshungulweyo.

3. Yibambe ngobunono kwaye ungayi "ncini" loo ndawo

Lungisa iindawo ngesixhobo esifakwe intloko yerabha: Amandla kufuneka alawulwe kwiikhilogram ezi-2 ukuya kwezi-3, njengokubamba iqanda ngesandla sakho ngobunono. Aliyi kutyibilika okanye liqhekeke. Isixhobo esingathethiyo seZHHIMG® sinokunciphisa ukungcangcazela ngexesha lokucubungula, ukuqinisekisa ukuba iindawo zizinzile kwaye zikhuselekile.

4. Qala ukucubungula: Njengokunika "ukucheba" inxalenye yeenwele

Umzekelo, qwalasela indlela esebenza ngayo i-semiconductor leads: Sebenzisa i-laser ye-femtosecond ukusika imo ye-copper alloy lead enobukhulu obuyi-0.1mm. Iibhloko ezimile okwe-V zegranite zinokufunxa ngaphezulu kwe-90% yokungcangcazela, nto leyo eyenza impazamo yokuma kwe-laser ibe ngaphantsi kwe-5μm - ilingane nokuthambekela okungekho ngaphezulu kwesinye kwishumi seenwele zomntu kubude be-1 millimeter.

Ukuhlolwa emva kokucubungula: Ilinganiswa ngesalathisi sokudayela esichanekileyo, ibhloko enomfanekiso we-ZHHIMG® V ibekwe kwindawo yokucubungula umngxuma onobubanzi obuyi-5mm, kunye nempazamo yobukhulu elawulwa ngaphakathi kwe-2μm, ebhityile ngokuphindwe ka-30 kuneenwele zomntu!

Usetyenziso "lweMicro-precision" kubomi bemihla ngemihla

Imfihlo yeetships ze-5G: Isakhelo se-lead esisetyenziselwa ukupakisha iitships kufuneka sinqunyulwe sibe ziimo ezintsonkothileyo kwiphepha lobhedu elinobukhulu obuyi-0.1mm. Iibhloko ezimile okwe-V zegranite zinokwenza ukusika kube mhle njengeblade, ukuqinisekisa ukuhanjiswa kwesignali okuzinzileyo kwetships.

"Amehlo" otyando olungenabungozi kangako: Xa kusetyenzwa i-catheter yentsimbi engatyibilikiyo enobubanzi obuyi-0.5mm, ibhloko enomfanekiso we-V yegranite inokuthintela le ndawo ukuba ingatyibiliki, yenze udonga lwangaphakathi lwe-catheter lube bushelelezi njengesipili, nto leyo evumela oogqirha ukuba basebenze ngokuchanekileyo.

Iv. Indlela Yokugcina Lo "Mncedisi Wokuchaneka"

Ukuhlamba rhoqo: Kwiziqwenga ezingama-50 ezicociweyo, sebenzisa amaza e-ultrasound "ukuhlamba" ibhloko enomfanekiso we-V, uhlambe inkunkuma yesinyithi kwaye usike ulwelo olukwimingxuma.

Uvavanyo lomzimba lonyaka: Ukulinganisa ubungakanani beebhloko ezimile okwe-V ngezixhobo zelaser. Utshintsho oluchanekileyo lweebhloko ezimile okwe-V zegranite ze-ZHHIMG® emva konyaka omnye zisetyenziswa lungaphantsi kwe-1μm, nto leyo ecothayo kunezinga lokukhula kweenwele zomntu!

Ngexesha elizayo xa ubona inxalenye encinci nechanekileyo, ungalibali ukuba kusenokubakho ibhloko enomfanekiso we-V enjengegranite "esebenzisa amandla" emva kwayo - ngenxa yobunzima bayo obuqinisiweyo kwiminyaka engamakhulu ezigidi, ixhasa ihlabathi le-microscopic yetekhnoloji yanamhlanje.

Ixesha leposi: Juni-18-2025