Kwicandelo lokulinganisa ngokuchanekileyo, i-profilometer sisixhobo esiphambili sokufumana idatha echanekileyo, kwaye isiseko, njengenxalenye ebalulekileyo ye-profilometer, amandla ayo okumelana nokuphazamiseka kwe-electromagnetic achaphazela ngokuthe ngqo ukuchaneka kweziphumo zokulinganisa. Phakathi kwezinto ezahlukeneyo zesiseko, i-granite kunye ne-cast iron zikhetho eziqhelekileyo. Xa kuthelekiswa neziseko ze-cast iron profilometer, iziseko ze-granite profilometer zibonise iingenelo ezibalulekileyo ekupheliseni ukuphazamiseka kwe-electromagnetic kwaye ziye zaba lukhetho olufanelekileyo lokulinganisa ngokuchanekileyo.

Impembelelo yokuphazamiseka kwe-electromagnetic ekulinganisweni kweeprofilometers

Kwindawo yanamhlanje yemizi-mveliso, ukuphazamiseka kwe-electromagnetic kukho kuyo yonke indawo. Ukususela kwimitha ye-electromagnetic eveliswa zizixhobo ezinkulu ezisebenza kwindawo yokusebenzela ukuya kukuphazamiseka kwesignali evela kwizixhobo ze-elektroniki ezingqongileyo, xa ezi mpawu zokuphazamiseka zichaphazela i-profilometer, ziya kubangela ukuphambuka kunye nokuguquguquka kwedatha yokulinganisa, kwaye zide zikhokelele ekugwebeni gwenxa kwenkqubo yokulinganisa. Kwimilinganiselo ye-contour efuna ukuchaneka kwinqanaba le-micrometer okanye le-nanometer, nokuphazamiseka kwe-electromagnetic okubuthathaka kunokubangela ukuba iziphumo zokulinganisa zilahlekelwe kukuthembeka, ngaloo ndlela zichaphazele umgangatho wemveliso kunye nokusebenza kakuhle kwemveliso.

Ingxaki yokuphazamiseka kwe-electromagnetic kwisiseko se-profilometer yesinyithi esityhidiweyo

Isinyithi esitshisiweyo sisixhobo sendabuko sokwenza iziseko kwaye sisetyenziswa kakhulu ngenxa yenkqubo yaso yokuphosa ebiza kancinci kunye nexabiso eliphantsi. Nangona kunjalo, isinyithi esitshisiweyo sinombane oqhuba kakuhle, nto leyo eyenza ukuba sibe sesichengeni sokungeniswa kwe-electromagnetic kwindawo ye-electromagnetic. Xa intsimi ye-electromagnetic ekhutshwa ngumthombo wokuphazamiseka kwe-electromagnetic yangaphandle isebenza kwisiseko sesinyithi esitshisiweyo, umsinga obangelwayo uya kuveliswa ngaphakathi kwesiseko, wenze umsinga we-electromagnetic eddy. Le misinga ye-electromagnetic eddy ayivelisi nje kuphela amasimi e-electromagnetic yesibini, iphazamisana nemiqondiso yokulinganisa yeprofilometer, kodwa ikwabangela ukuba isiseko sifudumale, nto leyo ebangela ukuguqulwa kobushushu kwaye ichaphazele ngakumbi ukuchaneka kokulinganisa. Ukongeza, ulwakhiwo lwesinyithi esitshisiweyo lukhululekile kwaye alukwazi ukuzikhusela ngokufanelekileyo imiqondiso ye-electromagnetic, nto leyo evumela ukuphazamiseka kwe-electromagnetic ukungena ngokulula kwisiseko kwaye kubangele ukuphazamiseka kwisekethe zokulinganisa zangaphakathi.

Inzuzo yokususa ukuphazamiseka kwe-electromagnetic kwisiseko se-granite profilometer

Iimpawu zokukhusela zendalo

I-Granite luhlobo lwelitye lendalo. Iikristale zayo zangaphakathi zeminerali ziqiniswe kakhulu kwaye isakhiwo sixinene. Sisixhobo sokukhusela esilungileyo. Ngokungafaniyo nentsimbi ephosiweyo, i-granite phantse ayiqhubi, oko kuthetha ukuba ayizukuvelisa imisinga ye-electromagnetic eddy kwindawo ye-electromagnetic, ngokuyintloko iphephe iingxaki zokuphazamiseka ezibangelwa kukungeniswa kwe-electromagnetic. Xa intsimi ye-electromagnetic yangaphandle isebenza kwisiseko se-granite, ngenxa yeempawu zayo zokukhusela, intsimi ye-electromagnetic ayinakwenza iluphu ngaphakathi kwesiseko, ngaloo ndlela inciphisa kakhulu ukuphazamiseka kwenkqubo yokulinganisa i-profilometer.

Ukusebenza kakuhle kokukhusela

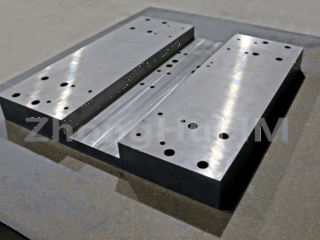

Ulwakhiwo oluxineneyo lwegranite luyinika amandla athile okukhusela i-electromagnetic. Nangona igranite ingenakuyithintela ngokupheleleyo imiqondiso ye-electromagnetic njengezinto zokukhusela isinyithi, inokusasaza kwaye ifunxe imiqondiso ye-electromagnetic kwisakhiwo sayo, ngaloo ndlela inciphisa amandla okuphazamiseka kwe-electromagnetic. Ukongeza, kwizicelo ezisebenzayo, isiseko se-granite profilometer sinokudityaniswa noyilo oluzinikeleyo lokukhusela i-electromagnetic, njengokongeza umaleko wokukhusela isinyithi, njl.njl., ukuphucula ngakumbi isiphumo sayo sokukhusela i-electromagnetic kunye nokubonelela ngendawo yokusebenza ezinzileyo ngakumbi kwinkqubo yokulinganisa.

Iimpawu zomzimba ezizinzileyo

Ukongeza ekupheliseni ngokuthe ngqo ukuphazamiseka kwe-electromagnetic, iipropati zomzimba ezizinzileyo ze-granite zikwanegalelo ngokungathanga ngqo ekuphuculeni amandla okulwa nokuphazamiseka kwe-profilometer. I-Granite inomlinganiselo ophantsi kakhulu wokwandiswa kobushushu kwaye ayitshintshi ubukhulu xa ubushushu butshintsha. Oku kuthetha ukuba kwiimeko apho ukuphazamiseka kwe-electromagnetic kunokubangela utshintsho kubushushu bendawo, isiseko se-granite sisenokugcina imo kunye nobukhulu obuzinzileyo, ukuqinisekisa ukuchaneka kwesalathiso sokulinganisa kunye nokuphepha iimpazamo ezongezelelweyo zokulinganisa ezenziwe ngenxa yokuguquguquka kwesiseko.

Namhlanje, ekufuneni ukulinganisa okuchanekileyo, iziseko ze-granite profilometer, ezineempawu zazo zokukhusela zendalo, ukusebenza kakuhle kokukhusela kunye neempawu zomzimba ezizinzileyo, zingcono kakhulu kuneziseko ze-cast iron profilometer ekupheliseni ukuphazamiseka kwe-electromagnetic. Ukukhetha i-profilometer enesiseko se-granite kunokugcina umlinganiselo ozinzileyo nochanekileyo kwiindawo ezintsonkothileyo ze-electromagnetic, kubonelela ngeziqinisekiso zokulinganisa ezinokuthenjwa kumashishini aneemfuno ezichanekileyo kakhulu ezifana nokuvelisa nge-elektroniki, ukucutshungulwa koomatshini okuchanekileyo, kunye ne-aerospace, kunye nokunceda amashishini aphucule umgangatho wemveliso kunye nokukhuphisana.

Ixesha leposi: Meyi-12-2025