Kwimveliso yanamhlanje echanekileyo, ukukhetha isiseko somatshini kubaluleke kakhulu ekufezekiseni ukuchaneka okuphezulu, uzinzo, kunye nokuthembeka kwexesha elide. Amashishini aqala kukwenziwa kwe-semiconductor ukuya kwi-optics echanekileyo kakhulu axhomekeke kakhulu kwiziseko ezibonelela ngokusebenza okuzinzileyo kwesakhiwo. Phakathi kwezinto ezixoxwa kakhulu kule meko yi-granite kunye ne-cast iron. Nganye ineempawu zomzimba ezahlukeneyo, iingenelo, kunye nemida echaphazela uyilo lwenkqubo, ukugcinwa, kunye neendleko zomjikelo wobomi.

Eli nqaku liphonononga umahluko phakathi kweziseko zomatshini wegranite kunyeiziseko zoomatshini besinyithi, igxininisa abavelisi abaphambili beziseko zoomatshini begranite, kwaye ihlola iingqwalasela ezichanekileyo zesiseko soomatshini kwizicelo zoshishino zanamhlanje. Ingxoxo ibonisa iindlela ezenzeka eYurophu naseMntla Melika kwaye ihambelana nokuziphatha kokukhangela okuvela kwiingcali zobunjineli kunye nokuthengwa kwempahla ezifuna ulwalathiso lobuchwephesha oluthembekileyo.

Indima yeZiseko zoMatshini oQikelelweyo

Isiseko somatshini ochanekileyo singaphezulu nje kwesakhiwo senkxaso—sichaza i-geometry yesalathiso seenkqubo zokuhamba, izixhobo zokulinganisa, kunye nemisebenzi yokusika okanye yokuhlanganisa. Uzinzo, ukuziphatha kobushushu, kunye neempawu zokudambisa ukungcangcazela kwesiseko zichaphazela ngokuthe ngqo ukusebenza kwenkqubo kunye nokuphindaphinda kokulinganisa.

Imisebenzi ephambili

- Inkxaso yoLwakhiwo:Ibonelela ngokuqina kwezinto ezifakelweyo kwaye iqinisekisa uzinzo olulinganayo phantsi komthwalo.

- Ukudambisa ukungcangcazela:Inciphisa ukudluliselwa kokungcangcazela kwendalo okanye kokusebenza kwiindawo ezibuthathaka.

- Uzinzo lobushushu:Inciphisa ukwanda okanye ukucutheka ngotshintsho lobushushu ukuze kugcinwe ulungelelwaniso kunye nokulinganiswa.

- Ubude bexesha:Iqinisekisa ukusebenza rhoqo kwixesha elide lenkonzo ngaphandle kokulungiswa kakhulu.

Ukuqonda le misebenzi kunceda iinjineli ukuba ziphonononge ukhetho lwezinto eziphathekayo kwaye ziphucule uyilo lomatshini.

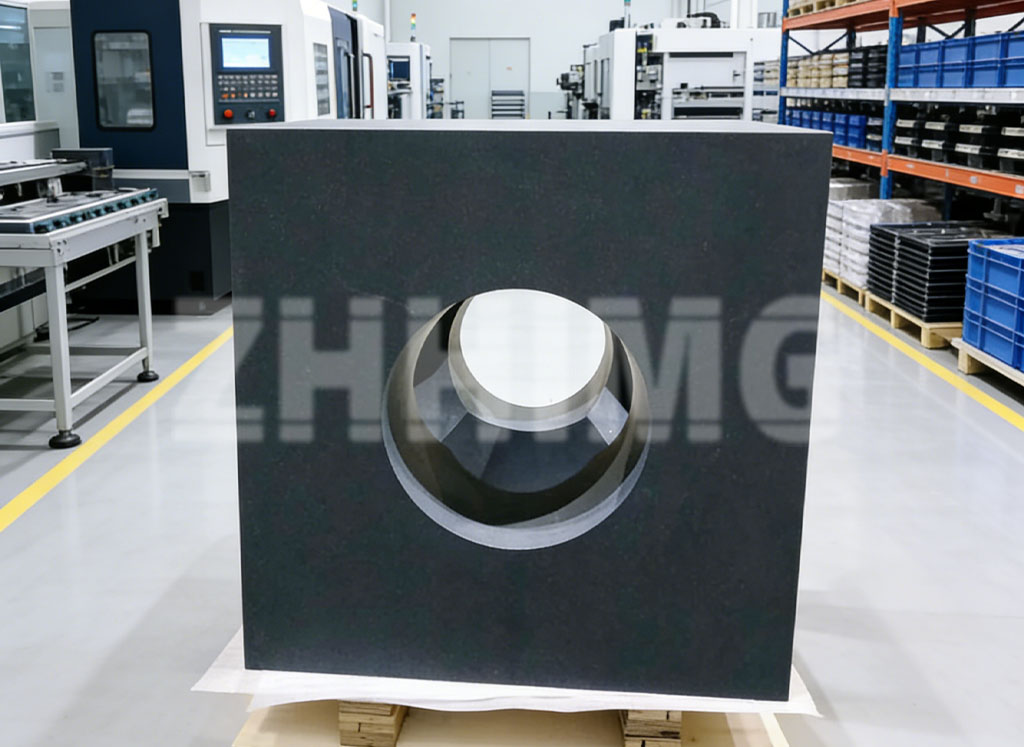

Iziseko zoomatshini beGranite: Iipropati kunye neenzuzo

I-granite ibisoloko ithandwa kakhulu kwiziseko ezichanekileyo, ngakumbi kwi-oomatshini bokulinganisa abalungelelanisiweyo (ii-CMM), iinkqubo zelaser, kunye namaqonga okuhlola optical.

Iipropati Zomzimba

- Ukwanda kobushushu obuphantsi:I-Granite ibonakalisa utshintsho oluncinci ngobukhulu kunye nokuguquguquka kobushushu, okuncedisa ekulungelelanisweni okuzinzileyo.

- Ubunzima Obuninzi:Ubunzima bayo obuqhelekileyo buyayithomalalisa ngempumelelo intshukumo.

- Ukuziphatha kwe-Isotropic:Iimpawu zomzimba ezifanayo kuzo zonke iindlela ziyanciphisa ukugoba okanye ukugoba phantsi komthwalo.

- Ukumelana nokugqwala:Ngokungafaniyo nesinyithi, i-granite ayivuthisi okanye yonakale, ifuna unyango oluncinci okanye olungakhuseliyo.

Iingenelo kwizicelo zokuchaneka

- Ukudambisa ukungcangcazela:I-granite ngokwemvelo ifunxa ukungcangcazela okuphezulu, iphucula umlinganiselo kunye nokuphindaphinda kwenkqubo.

- Uzinzo Lwexesha Elide:Igcina ithambile kwaye ithe tye kangangeminyaka emininzi ngaphandle kokulungiswa kakhulu.

- Ukuchaneka koBume:Ilungele ukusetyenziswa okufuna ukunyamezelana okuqinileyo kwii-microns.

Abavelisi Abaphambili

Abavelisi beziseko zoomatshini begranite bagxile ekutsaleni ngokuchanekileyo okuphezulu,ukugqitywa komphezulu, kunye neenkqubo zokulawula umgangatho ukuze kunikezelwe ngamaqonga athe tyaba nazinzileyo. Ababoneleli abaphambili kwihlabathi liphela baquka iinkampani ezineziqinisekiso ze-ISO 9001, ISO 14001, kunye ne-CE eziqinisekisa ukukhethwa kwezinto, imigangatho yokwenziwa kwemishini, kunye nokuhlolwa okulinganayo.

Iziseko zoomatshini besinyithi: iipropati kunye nezicelo

Isinyithi esitshisiweyo besisoloko sisisiseko sokwakhiwa kwezixhobo zoomatshini zemveli kwaye sihlala sixhaphakile kwizicelo ezifuna ukuqina okuphezulu kunye nomthamo womthwalo.

Iipropati Zomzimba

- Ukwanda kwe-Thermal Coefficient ephezulu:Ibuthathaka ngakumbi kutshintsho lobushushu xa ithelekiswa negranite.

- Ukufuma okuphakathi:Izinto ezifakwe kwi-graphite kwisinyithi esingwevu zinika ukufunxwa kokungcangcazela, kodwa zingaphantsi kunegranite.

- Ukuqina Okuphezulu:Ukumelana okuhle kakhulu nokugoba kunye nokuguqulwa phantsi kwemithwalo enzima.

Iingenelo kunye namatyala okusetyenziswa

- Izicelo Ezinzima:Ifanelekile kakhulu kwizixhobo zoomatshini,Oomatshini bokugaya be-CNC, kunye neenkqubo ezinkulu zoshishino.

- Ukusebenza kakuhle kweendleko:Ngokubanzi iindleko zezinto zokwakha ziphantsi xa kuthelekiswa negranite ekumgangatho ophezulu.

- Ubuchule bokusebenza:Ingafakwa ngokulula kwi-geometries ezintsonkothileyo kwaye idityaniswe neempawu zoomatshini.

Imida

- Uvakalelo lobushushu:Ifuna ulawulo lokusingqongileyo okanye imbuyekezo esebenzayo kwimisebenzi echanekileyo.

- Iimfuno zoLondolozo:Inokuchaphazeleka kukugqwala; ingafuna ukulungiswa rhoqo ukuze kugcinwe ukuchaneka.

Uhlalutyo lokuthelekisa: I-Granite vs Iron Cast

| Uphawu | Igranite | Jula i-ayini |

|---|---|---|

| Ukwandiswa kobushushu | Iphantsi; uzinzo oluhle kakhulu | Iphezulu; inovelwano kutshintsho lobushushu |

| Ukudambisa ukungcangcazela | Igqwesile | Iphakathi |

| Umthamo woMthwalo | Phakathi; kuxhomekeke kwijometri | Phezulu; ixhasa oomatshini abanzima |

| Ulondolozo | Okuncinci | Ifuna ukhuseleko kunye nokugcinwa rhoqo |

| Umsebenzi wobomi | Iminyaka emininzi kunye nokusebenza okuqhubekayo | Ixesha elide, kodwa linokuwohloka xa liphantsi kokugqwala okanye uxinzelelo lobushushu |

| Izicelo eziqhelekileyo | I-CMM, iinkqubo ze-laser, iibhentshi ze-optical | Oomatshini be-CNC, izixhobo ezinkulu zoshishino |

Imiphumo kubaYili

I-granite iyathandwa apho ukungcangcazela, ukuzinza kobushushu, kunye nokuchaneka kakhulu zezona zinto ziphambili. Isinyithi esitshisiweyo sihlala sifanelekile kwimisebenzi enzima apho ukuqina kunye nomthamo wokuthwala umthwalo kubaluleke ngakumbi kunozinzo olupheleleyo lwe-micrometer.

Ukukhetha isiseko somatshini ochanekileyo

Iinjineli kufuneka zihlole izinto ezininzi xa zikhetha phakathi kweziseko zegranite kunye nezesinyithi:

- Iimfuno zesicelo:Misela ukuchaneka okufunekayo, umthwalo, kunye neemeko zokusingqongileyo.

- Izinto eziqwalaselwayo kuhlahlo-lwabiwo mali:Linganisa iindleko zezinto kunye neenzuzo zokusebenza kunye nokugcinwa komjikelo wobomi.

- Ukuhlanganiswa kweNkqubo:Cinga ngokuhambelana nezigaba zokuhamba, izinzwa, kunye nezixhobo ezincedisayo.

- Ubungcali boMboneleli:Sebenzisana nabavelisi abanamava ukuqinisekisa umgangatho kunye nokuthobela imigangatho echanekileyo.

Izifundo zeTyala kunye neMizekelo yoShishino

Oomatshini bokulinganisa abaQokelelweyo (ii-CMM)

Iziseko zegranite ziqhelekile kwiiCMM ezichanekileyo ngenxa yozinzo lwazo kunye nokumelana nokuguguleka. Iziseko zesinyithi ezibunjiweyo zingasetyenziswa kwiinkqubo ezinkulu, ezingabalulekanga kangako apho kulindeleke khona imithwalo ephezulu.

Iinkqubo zokuSika ngeLaser kunye neMetrology

Iziseko zegranite zibonelela ngokunciphisa ukungcangcazela okubalulekileyo ekucutshungulweni kwelaser, ukuphucula umgangatho wokusika kunye nokunciphisa iimpazamo kwizicelo ezincinci.

Izixhobo zoomatshini

Isinyithi esitshisiweyo sihlala siyindlela ebalaseleyo yokusika kunye neeplatifomu zoomatshini apho izinto zokusebenza ezinzima kunye namandla okusika aphezulu afuna ukuqina okukhulu kunye nokuqina kwesakhiwo.

Isiphelo

Zombini iziseko zoomatshini begranite kunye nesinyithi esityhidiweyo zidlala indima ebalulekileyo ekuveliseni ngokuchanekileyo. Igranite igqwesile kwizicelo ezifuna uzinzo oluphezulu, ukudambisa ukungcangcazela, kunye nokuqina kobushushu, okwenza ukuba ifaneleke kwi-CMMs, iinkqubo ze-laser, kunye ne-optical metrology. Isinyithi esityhidiweyo sifanelekile ngakumbi kwizixhobo zoomatshini ezinzima apho ukuqina kunye nomthamo womthwalo ulawula khona.

Ukusebenzisana nabavelisi beziseko zoomatshini begranite abanamava kuqinisekisa ukuba iimfuno zokuchaneka ziyafezekiswa ngelixa kunciphisa ukugcinwa kwexesha elide. Ngokuvavanya ngononophelo iimfuno zesicelo, iimeko zokusingqongileyo, kunye neempawu zezinto, iinjineli zinokukhetha isiseko esifanelekileyo sokwandisa ukusebenza kunye nokuthembeka kwezixhobo zokuchaneka.

Ixesha leposi: Jan-23-2026