Kwicandelo lokulinganisa ngokuchanekileyo, umatshini wokulinganisa onama-three-coordinate sisixhobo esiphambili sokulawula umgangatho wemveliso, kwaye isiseko sisebenza njengesiseko sokusebenza kwayo okuzinzileyo. Ukusebenza kwayo kokuguquguquka kobushushu kumisela ngokuthe ngqo ukuchaneka kokulinganisa. I-granite kunye ne-cast iron, njengezixhobo ezimbini ezisisiseko, ziye zatsala ingqalelo enkulu kwiiyantlukwano zazo kukuguquguquka kobushushu. Ngeteknoloji yokubona ngeliso imifanekiso yobushushu, singatyhila ngokuthe ngqo umahluko obalulekileyo kukuqina kobushushu phakathi kwezi zimbini, sinike isiseko sesayensi sokukhetha izixhobo kwishishini lokuvelisa ngokuchanekileyo.

Ukuguqulwa kobushushu: "Umbulali Ongabonakaliyo" Ochaphazela Ukuchaneka koMlinganiselo oNqunyiweyo kaThathu

Umatshini wokulinganisa onama-three-coordinate ufumana idatha enamacala amathathu ngokudibana kweprobe nento elinganiswayo. Naluphi na utshintsho lobushushu lwesiseko luya kubangela ukuba ireferensi yokulinganisa itshintshe. Kwimeko-bume yemizi-mveliso, izinto ezifana nokuveliswa kobushushu ngexesha lokusebenza kwezixhobo kunye nokuguquguquka kobushushu bendalo konke kunokubangela ukwanda kobushushu okanye ukucutheka kwesiseko. Utshintsho lobushushu oluncinci lunokubangela ukuphambuka kwendawo kwiprobe yokulinganisa, ekugqibeleni kukhokelela kwiimpazamo zokulinganisa. Kumashishini aneemfuno ezichanekileyo kakhulu ezifana ne-aerospace kunye ne-semiconductors, iimpazamo ezibangelwa kukuguquguquka kobushushu zinokukhokelela ekususweni kwemveliso okanye ekuwohlokeni kokusebenza. Ke ngoko, ukuzinza kobushushu besiseko kubaluleke kakhulu.

Umfanekiso we-thermal: Ubona umahluko kwi-thermal deformation

Abafoti be-thermal banokuguqula usasazo lobushushu kumphezulu wento lube yimifanekiso ebonakalayo. Ngokuhlalutya utshintsho lobushushu kwiindawo ezahlukeneyo, banokubonisa ngokubonakalayo imeko yokuguquguquka kobushushu. Kolu vavanyo, sikhethe iziseko zomatshini zokulinganisa i-granite kunye ne-cast iron ezintathu-coordinate ze-specification efanayo, salinganisa ukuveliswa kobushushu ngexesha lokusebenza kwezixhobo phantsi kwendawo efanayo, saza sasebenzisa i-thermal imager ukurekhoda utshintsho lobushushu kunye neenkqubo zokuguquguquka kobushushu kuzo zombini.

Isiseko sesinyithi esityhidiweyo: Ukuguquguquka okuphawulekayo kobushushu kunye nozinzo oluxhalabisayo

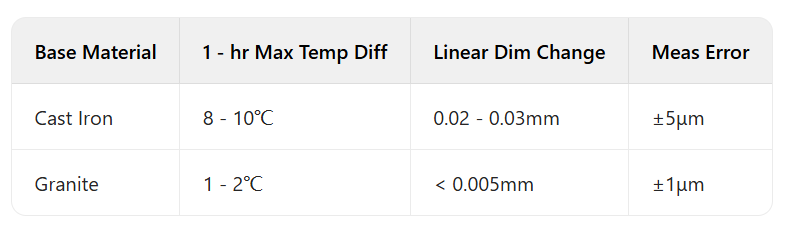

Umfanekiso womfanekiso wobushushu ubonisa ukuba emva kokuba isiseko sesinyithi esityhidiweyo sisebenze imizuzu engama-30, kukho ukusasazwa okungalinganiyo kobushushu bomphezulu. Ngenxa yokuguquguquka kobushushu obungalinganiyo kwesinyithi esityhidiweyo, ubushushu kwindawo yasekuhlaleni yesiseko bunyuka ngokukhawuleza, kwaye umahluko phakathi kobushushu obuphezulu nobuphantsi bunokufikelela kwi-8-10 ℃. Phantsi kwesenzo soxinzelelo lobushushu, isiseko sesinyithi esityhidiweyo sidlula kwiinguqu ezincinci ezibonakalayo emehlweni. Kwafunyaniswa ngezixhobo zokulinganisa ezichanekileyo ukuba utshintsho kubungakanani baso obuthe tye lufikelele kwi-0.02-0.03mm. Olu tshintsho lunokubangela ukuba impazamo yokulinganisa yande iye kwi-±5μm, nto leyo echaphazela kakhulu ukuchaneka kokulinganisa. Ukongeza, emva kokuba isiseko sesinyithi esityhidiweyo siyeke ukusebenza, ubushushu buyaphela kancinci kwaye kuthatha ixesha elide ukuya kwiyure e-1 ukuya kwezi-2 ukubuyela kwimeko yokuqala, nto leyo ethintela kakhulu amandla okusebenza aqhubekayo esixhobo.

Isiseko segranite: Uzinzo oluhle kakhulu lobushushu luqinisekisa ukuchaneka komlinganiselo

Ngokwahlukileyo koko, isiseko segranite sibonisa uzinzo oluhle kakhulu lobushushu ngexesha lokusebenza. Imifanekiso yemifanekiso yobushushu ibonisa ukuba usasazo lobushushu bomphezulu lufana. Emva kweyure enye yokusebenza, umahluko omkhulu wobushushu kumphezulu wesiseko yi-1-2 ℃ kuphela. Oku kubangelwa yi-coefficient ephantsi kakhulu yokwandiswa kobushushu begranite (5-7 × 10⁻⁶/℃) kunye nokufana kwayo okuhle kokuqhuba kobushushu. Emva kovavanyo, umahluko olinganayo wesiseko segranite phantsi kweemeko ezifanayo zokusebenza ungaphantsi kwe-0.005mm, kwaye impazamo yokulinganisa inokulawulwa ngaphakathi kwe-±1μm. Kwanasemva kokusebenza okuqhubekayo ixesha elide, isiseko segranite sisenokugcina imo ezinzileyo, kwaye emva kokuba umsebenzi uyekile, ubushushu bubuyela ngokukhawuleza kwimeko ezinzileyo, bubonelela ngereferensi ethembekileyo yokulinganisa okulandelayo.

Ngokusebenzisa indlela ecacileyo yokubonisa kunye nothelekiso lwedatha yemifanekiso yobushushu, inzuzo yegranite ekuzinzeni kobushushu iyabonakala. Kumashishini avelisa izinto alandela umlinganiselo ochanekileyo, ukukhetha umatshini wokulinganisa onama-three coordinate anesiseko segranite kunokunciphisa ngempumelelo iimpazamo zokulinganisa ezibangelwa kukuguquguquka kobushushu kwaye kuphucule ukuchaneka kunye nokusebenza kakuhle kokuhlolwa kwemveliso. Njengoko ishishini lokuvelisa lisiya kumgangatho ophezulu kunye nobukrelekrele, iziseko zegranite, ezinozinzo lwazo olubalaseleyo lobushushu, ziya kuba zezona zinto zikhethwayo kwiimashini zokulinganisa ezinama-three coordinate kunye nezixhobo ezichanekileyo ngakumbi, ziqhubela phambili umgangatho wolawulo loshishino ukuya kubude obutsha.

Ixesha leposi: Meyi-13-2025