Kwindlela yokuvelisa i-semiconductor, ukusika i-wafer yinkqubo ebalulekileyo efuna ukuchaneka okukhulu. Ukukhetha izinto ezisetyenziswa kwizixhobo kuchaphazela kakhulu ukusebenza. Masithelekise i-granite nezinye izinto eziqhelekileyo ukuze sibone ukuba kutheni ihlala iphuma phezulu kwizixhobo zokusika i-wafer.

I-Granite: I-Cut Ngaphezu Kwezinye

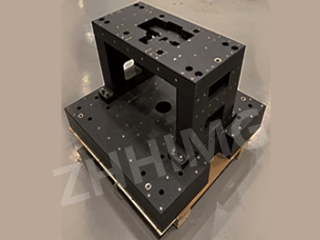

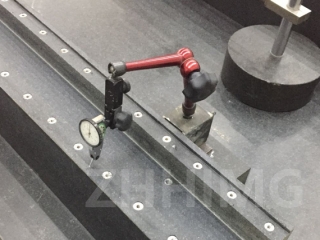

Uzinzo: I-Granite, enobunzima obumalunga ne-3100 kg/m³ njengomnikelo we-ZHHIMG®, inika uzinzo olumangalisayo. Ulwakhiwo lwayo oluzinzileyo lunciphisa ukungcangcazela ngexesha lenkqubo yokusika i-wafer. Ngokwahlukileyo koko, izinto ezifana ne-aluminium zinokuba lula ukuhamba phantsi koxinzelelo lwemisebenzi yokusika ngesantya esiphezulu. Olu zinzo luqinisekisa ukuba isixhobo sokusika sihlala sibekwe ngokuchanekileyo, nto leyo ekhokelela ekusikeni ngokuchanekileyo kunye nee-wafers ezikumgangatho ophezulu.

Ukumelana nobushushu: I-Granite ine-coefficient yokwandisa ubushushu ephantsi. Kwi-wafer cutting, apho ukuguquguquka kobushushu kunokwenzeka ngenxa yobushushu obuveliswa yinkqubo yokusika okanye imeko-bume yokuvelisa, ukuzinza kobushushu be-granite kuyinzuzo. Ayikhuli okanye inciphe kakhulu ngotshintsho lobushushu, nto leyo egcina ulungelelwaniso lwezixhobo zokusika. Iintsimbi ezifana nentsimbi, kwelinye icala, zinokufumana ukwanda kobushushu okukhulu, okunokukhokelela ekungalungelelaniseni nasekusikeni okungachanekanga.

Ukudambisa Ukungcangcazela: Iimpawu zendalo zokungcangcazela - ukudambisa i-granite ziyamangalisa. Ngexesha lokusika i-wafer, ukungcangcazela kunokubangela ukuba isixhobo sokusika siphambuke kwindlela ebesiyifuna, nto leyo ekhokelela ekuqhekekeni okanye ekuqhekekeni okungalinganiyo. I-granite ifunxa kwaye ichithe ezi ngcangcazela ngempumelelo, idale ukusebenza okugudileyo kokusika. Izinto ezifana nee-composites ezisekelwe kwiplastiki azinalo olu buchule bokungcangcazela - ukudambisa, nto leyo eyenza ukuba zingafaneleki kangako ekusikweni kwe-wafer ngokuchanekileyo.

Ukuthelekisa neCast Iron

Isinyithi esitshisiweyo siyindlela eqhelekileyo yokukhetha iziseko zoomatshini. Nangona kunjalo, inemida yayo xa ithelekiswa negranite. Nangona isinyithi esitshisiweyo sinikezela uzinzo oluthile, sinzima kunegranite xa kuthelekiswa namandla aso. Olu bunzima bongezelelweyo lunokubangela imingeni ngexesha lokufakwa kwezixhobo kunye nokuhamba kwazo. Ukongeza, isinyithi esitshisiweyo sichaphazeleka ngakumbi kukugqwala ngokuhamba kwexesha, ingakumbi kwiindawo zokwenza i-semiconductor apho iikhemikhali zinokubakho khona. Igranite, ekubeni ingasebenzi kakuhle ngokweekhemikhali, ayihlupheki kule ngxaki, iqinisekisa ukuqina nokuthembeka kwexesha elide.

Ityala Elichasene Nemarble

Abanye basenokuyithatha imabula njengenye indlela, kodwa ayisebenzi kakuhle kwiinkalo ezininzi kwizixhobo zokusika iiwafer. Imabula inobunzima obuphantsi kwaye ngokubanzi ayizinzanga kunegranite. Ikwanazo neembobo ezininzi, nto leyo enokuyenza ibe sesichengeni sokonakala ngenxa yokufuma kunye neekhemikhali kwindawo yokuvelisa. Kwindlela yokusika iiwafer, apho ukuchaneka kunye nokuqina kubalulekile, iipropati zomzimba zemabula azihambelani neemfuno njengoko injalo igranite.

Ukuqukumbela, xa kufikwa ekukhetheni izinto zokusika iziseko zezixhobo zokusika i-wafer, i-granite, ingakumbi i-granite ekumgangatho ophezulu efana naleyo inikezelwa yi-ZHHIMG®, iyabonakala. Uzinzo lwayo, ukumelana nobushushu, kunye nokungcangcazela - amandla okudambisa kwenza ukuba ibe lolona khetho lufanelekileyo lokufezekisa ukuchaneka okuphezulu okufunekayo ekusikeni i-wafer ye-semiconductor. Nangona kukho ezinye izinto ezikhoyo, indibaniselwano eyahlukileyo yeempawu ze-granite iyinika ithuba elicacileyo kolu setyenziso lunzima.

Ixesha lokuthumela: Juni-03-2025