Kwimveliso yokusika i-laser ye-LCD/LED, ixesha lokungasebenzi liyinto ephambili echaphazela ukusebenza kakuhle kwemveliso kunye neendleko. Isiseko se-granite esichanekileyo, esineempawu zaso ezikhethekileyo, sinokunciphisa ixesha lokungasebenzi kwaye sizise iingenelo ezininzi kwimveliso.

Uzinzo olubalaseleyo kunye nokumelana nokungcangcazela

I-Granite ineempawu zendalo zokufunxa ukungcangcazela, kwaye isakhiwo sayo se-molecular sinokufunxa kwaye sithintele ukungcangcazela okwenziwa ngexesha lenkqubo yokusika i-laser. Xa kusenziwa ukusika i-laser ye-LCD/LED, ukuba ukungcangcazela okuphezulu kwezixhobo (ngesiqhelo phakathi kwe-20 kunye ne-50Hz) akucinezelwanga ngokufanelekileyo, kuya kukhokelela ekunciphiseni ukuchaneka kokusika, kubangele iimveliso ezineziphene okanye ezilahliweyo, kwaye emva koko kufuneke ukuba umatshini uvalwe ukuze kulungiswe kwakhona kwaye kulungiswe iiparameter. Isiseko se-granite esichanekileyo kakhulu sinokunciphisa i-amplitude yokungcangcazela ngaphezulu kwe-60%, sigcine intloko yokusika i-laser izinzile ngexesha lokusebenza ngesantya esiphezulu, senza umda wokusika ube bushelelezi, kunciphisa kakhulu imiba yomgangatho wokusika ebangelwa kukungcangcazela, kwaye kuthintele ukuvalwa rhoqo ukuze kulungiswe.

I-coefficient ephantsi kakhulu yokwandiswa kobushushu

Ngexesha lenkqubo yokusika nge-laser ye-LCD/LED, ubushushu buyaveliswa kwaye ubushushu obujikeleze umhlaba bunokutshintshatshintsha, nto leyo evavanya uzinzo lobushushu besiseko sezixhobo. Izixhobo eziqhelekileyo zinomlinganiselo ophezulu wokwanda kobushushu kwaye zinokuguquguquka xa ubushushu butshintsha, nto leyo echaphazela ukuchaneka kokusika. Umlinganiselo wokwandiswa kobushushu begranite yi-1/20 kuphela yentsimbi. Nokuba kwindawo enomlinganiselo omkhulu wokuguquguquka kobushushu (njenge--20℃ ukuya kwi-50℃), isenokugcina ukuchaneka kokuma ngaphakathi kwe-±2μm. Oku kuqinisekisa ukuba ngexesha lemisebenzi yokusika eqhubekayo ixesha elide, akuyi kubakho kuvalwa rhoqo ukuze kuphinde kulinganiswe indlela yokusika kunye nendawo ngenxa yokuguquguquka kobushushu besiseko, okuqinisekisa ukuhambelana kunye nokuzinza kokuchaneka kokusika.

Ukumelana nokuguguleka okuphezulu kunye nobomi benkonzo ende

Isiseko segranite esichanekileyo kakhulu sinobunzima obuphezulu kunye nokumelana nokuguguleka okunamandla, kunye nobunzima beMohs obuyi-6-7, obuphindwe kathathu kunokumelana nokuguguleka kwentsimbi eqhelekileyo. Ngexesha lokusebenza kwexesha elide kunye nokuphindaphinda okuphezulu kwezixhobo zokusika nge-laser, umphezulu wesiseko awuguguleki. Xa kuthelekiswa nezinye izixhobo ezisisiseko ezigugulekayo, iziseko zegranite azifuni ukulungiswa rhoqo okanye ukutshintshwa ngenxa yokuguguleka komphezulu, nto leyo eyandisa ubomi benkonzo iyonke yezixhobo kwaye inciphise ixesha lokungasebenzi elicwangcisiweyo lokugcinwa okubangelwa ziingxaki zokuguguleka kwesiseko.

Ukucubungula ngokuchanekileyo kunye nokuguquguquka

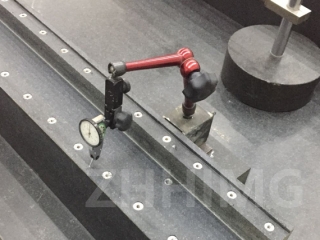

Iziseko zegranite ezichanekileyo kakhulu zanamhlanje zisebenzisa iindlela eziphambili zokucubungula, ezifana noomatshini be-CNC abajikelezayo ezintlanu, njl. Izalathisi ezichanekileyo ezifana nokuba tyaba kunye nokuthe tye ziphezulu kakhulu, kwaye ukuba tyaba kunokufikelela kwi-± 0.5μm/m. Olu hlaziyo oluchanekileyo lunokubonelela ngereferensi yokufakela echanekileyo yezixhobo zokusika nge-laser, okwenza ukuchaneka kwendibano yecandelo ngalinye lesixhobo kuphakame kwaye ukusebenza kuzinze ngakumbi. Okwangoku, isiseko segranite sinokwenziwa ngokwezifiso kwaye sicutshungulwe ngokweemfuno zezixhobo ezahlukeneyo zokusika nge-laser, ukufezekisa ukuhambelana okugqibeleleyo nezixhobo kunye nokunciphisa ukusilela kokusebenza kunye nexesha lokungasebenzi kokulungisa okubangelwa kukungalingani phakathi kwesiseko kunye nezixhobo.

Ukugcinwa okulula kunye nokubeka esweni ngobulumko

Ezinye iziseko zegranite ezichanekileyo kakhulu zixhotyiswe ngeenkqubo zokubeka esweni ezikrelekrele ezinokuqokelela idatha yexesha langempela efana nokungcangcazela, ubushushu kunye noxinzelelo lweziseko. Ngokuhlalutya ezi datha, iingozi zokungaphumeleli zinokuxelwa kwangaphambili, kwaye ukugcinwa kunokucwangciswa ngaphambi kokuba kwenzeke iimpazamo, kuthintelwe ixesha lokungasebenzi elibangelwa kukungasebenzi ngequbuliso. Ngaphezu koko, isiseko segranite ngokwaso sinesakhiwo esizinzileyo kunye nokumelana okunamandla kokugqwala. Ukugcinwa kwayo imihla ngemihla kulula, ngaphandle kwesidingo seenkqubo zokugcinwa ezintsonkothileyo, nto leyo enciphisa ngakumbi ixesha lokungasebenzi kokugcinwa.

Isiseko segranite esichanekileyo kakhulu sinika iziqinisekiso zokusebenza okuzinzileyo nokufanelekileyo kwemveliso yokusika i-laser ye-LCD/LED kwiinkalo ezininzi, kunciphisa kakhulu ixesha lokungasebenzi, kuphucula ukusebenza kakuhle kwemveliso, kunye nokunciphisa iindleko zemveliso iyonke. Lukhetho olufanelekileyo kwizixhobo zanamhlanje zokusika i-laser ye-LCD/LED. Isiseko segranite esichanekileyo kakhulu: Sinciphisa kakhulu ixesha lokungasebenzi kwe-laser ye-LCD/LED

Kwimveliso yokusika i-laser ye-LCD/LED, ixesha lokungasebenzi liyinto ephambili echaphazela ukusebenza kakuhle kwemveliso kunye neendleko. Isiseko se-granite esichanekileyo, esineempawu zaso ezikhethekileyo, sinokunciphisa ixesha lokungasebenzi kwaye sizise iingenelo ezininzi kwimveliso.

Uzinzo olubalaseleyo kunye nokumelana nokungcangcazela

I-Granite ineempawu zendalo zokufunxa ukungcangcazela, kwaye isakhiwo sayo se-molecular sinokufunxa kwaye sithintele ukungcangcazela okwenziwa ngexesha lenkqubo yokusika i-laser. Xa kusenziwa ukusika i-laser ye-LCD/LED, ukuba ukungcangcazela okuphezulu kwezixhobo (ngesiqhelo phakathi kwe-20 kunye ne-50Hz) akucinezelwanga ngokufanelekileyo, kuya kukhokelela ekunciphiseni ukuchaneka kokusika, kubangele iimveliso ezineziphene okanye ezilahliweyo, kwaye emva koko kufuneke ukuba umatshini uvalwe ukuze kulungiswe kwakhona kwaye kulungiswe iiparameter. Isiseko se-granite esichanekileyo kakhulu sinokunciphisa i-amplitude yokungcangcazela ngaphezulu kwe-60%, sigcine intloko yokusika i-laser izinzile ngexesha lokusebenza ngesantya esiphezulu, senza umda wokusika ube bushelelezi, kunciphisa kakhulu imiba yomgangatho wokusika ebangelwa kukungcangcazela, kwaye kuthintele ukuvalwa rhoqo ukuze kulungiswe.

I-coefficient ephantsi kakhulu yokwandiswa kobushushu

Ngexesha lenkqubo yokusika nge-laser ye-LCD/LED, ubushushu buyaveliswa kwaye ubushushu obujikeleze umhlaba bunokutshintshatshintsha, nto leyo evavanya uzinzo lobushushu besiseko sezixhobo. Izixhobo eziqhelekileyo zinomlinganiselo ophezulu wokwanda kobushushu kwaye zinokuguquguquka xa ubushushu butshintsha, nto leyo echaphazela ukuchaneka kokusika. Umlinganiselo wokwandiswa kobushushu begranite yi-1/20 kuphela yentsimbi. Nokuba kwindawo enomlinganiselo omkhulu wokuguquguquka kobushushu (njenge--20℃ ukuya kwi-50℃), isenokugcina ukuchaneka kokuma ngaphakathi kwe-±2μm. Oku kuqinisekisa ukuba ngexesha lemisebenzi yokusika eqhubekayo ixesha elide, akuyi kubakho kuvalwa rhoqo ukuze kuphinde kulinganiswe indlela yokusika kunye nendawo ngenxa yokuguquguquka kobushushu besiseko, okuqinisekisa ukuhambelana kunye nokuzinza kokuchaneka kokusika.

Ukumelana nokuguguleka okuphezulu kunye nobomi benkonzo ende

Isiseko segranite esichanekileyo kakhulu sinobunzima obuphezulu kunye nokumelana nokuguguleka okunamandla, kunye nobunzima beMohs obuyi-6-7, obuphindwe kathathu kunokumelana nokuguguleka kwentsimbi eqhelekileyo. Ngexesha lokusebenza kwexesha elide kunye nokuphindaphinda okuphezulu kwezixhobo zokusika nge-laser, umphezulu wesiseko awuguguleki. Xa kuthelekiswa nezinye izixhobo ezisisiseko ezigugulekayo, iziseko zegranite azifuni ukulungiswa rhoqo okanye ukutshintshwa ngenxa yokuguguleka komphezulu, nto leyo eyandisa ubomi benkonzo iyonke yezixhobo kwaye inciphise ixesha lokungasebenzi elicwangcisiweyo lokugcinwa okubangelwa ziingxaki zokuguguleka kwesiseko.

Ukucubungula ngokuchanekileyo kunye nokuguquguquka

Iziseko zegranite ezichanekileyo kakhulu zanamhlanje zisebenzisa iindlela eziphambili zokucubungula, ezifana noomatshini be-CNC abajikelezayo ezintlanu, njl. Izalathisi ezichanekileyo ezifana nokuba tyaba kunye nokuthe tye ziphezulu kakhulu, kwaye ukuba tyaba kunokufikelela kwi-± 0.5μm/m. Olu hlaziyo oluchanekileyo lunokubonelela ngereferensi yokufakela echanekileyo yezixhobo zokusika nge-laser, okwenza ukuchaneka kwendibano yecandelo ngalinye lesixhobo kuphakame kwaye ukusebenza kuzinze ngakumbi. Okwangoku, isiseko segranite sinokwenziwa ngokwezifiso kwaye sicutshungulwe ngokweemfuno zezixhobo ezahlukeneyo zokusika nge-laser, ukufezekisa ukuhambelana okugqibeleleyo nezixhobo kunye nokunciphisa ukusilela kokusebenza kunye nexesha lokungasebenzi kokulungisa okubangelwa kukungalingani phakathi kwesiseko kunye nezixhobo.

Ukugcinwa okulula kunye nokubeka esweni ngobulumko

Ezinye iziseko zegranite ezichanekileyo kakhulu zixhotyiswe ngeenkqubo zokubeka esweni ezikrelekrele ezinokuqokelela idatha yexesha langempela efana nokungcangcazela, ubushushu kunye noxinzelelo lweziseko. Ngokuhlalutya ezi datha, iingozi zokungaphumeleli zinokuxelwa kwangaphambili, kwaye ukugcinwa kunokucwangciswa ngaphambi kokuba kwenzeke iimpazamo, kuthintelwe ixesha lokungasebenzi elibangelwa kukungasebenzi ngequbuliso. Ngaphezu koko, isiseko segranite ngokwaso sinesakhiwo esizinzileyo kunye nokumelana okunamandla kokugqwala. Ukugcinwa kwayo imihla ngemihla kulula, ngaphandle kwesidingo seenkqubo zokugcinwa ezintsonkothileyo, nto leyo enciphisa ngakumbi ixesha lokungasebenzi kokugcinwa.

Isiseko segranite esichanekileyo kakhulu sinika iziqinisekiso zokusebenza okuzinzileyo nokufanelekileyo kwemveliso yokusika i-laser ye-LCD/LED kwiinkalo ezininzi, kunciphisa kakhulu ixesha lokungasebenzi, kuphucula ukusebenza kakuhle kwemveliso, kunye nokunciphisa iindleko zemveliso iyonke. Lukhetho olufanelekileyo kwizixhobo zanamhlanje zokusika i-laser ye-LCD/LED.

Ixesha leposi: Juni-17-2025