Kwimeko yanamhlanje yokuvelisa ephezulu, ukuchaneka akusekho nzuzo yokhuphiswano—yinto ebalulekileyo. Njengoko amashishini afana ne-aerospace, ukwenziwa kwe-semiconductor, i-photonics, kunye ne-metrology ephucukileyo eqhubeka nokunciphisa imida yokuchaneka, izixhobo ezisetyenziswa ngaphakathi kwiinkqubo zokulinganisa kunye nezixhobo ze-optical ziye zabaluleka njenge-algorithms yesoftware okanye iinkqubo zolawulo. Kulapho izisombululo ze-ceramic zoshishino, kuqukai-ceramic echanekileyo ye-CMM, i-precision ceramic ye-photonics, kunye ne-advanced precision SiN ceramic, zidlala indima ebalulekileyo ngakumbi.

Izixhobo zeseramikhi zoshishino ziguqukele ngaphaya komfanekiso wazo wendabuko njengezinto ezilula ezingagugiyo. Iiseramikhi zobugcisa zanamhlanje zizinto ezakhiwe ngobuchule ezinezakhiwo ezincinci ezilawulwa ngononophelo, ezibonelela ngokusebenza okuqikelelweyo koomatshini, ubushushu, kunye neekhemikhali. Xa kuthelekiswa neentsimbi, iiseramikhi zibonelela ngozinzo oluphezulu, ukwanda okuphantsi kobushushu, kunye nokumelana okuhle nokugqwala kunye nokuguga. Ezi mpawu zibaluleke kakhulu kwiindawo apho ii-microns—okanye ii-nanometers—zibalulekile.

Kwiimatshini zokulinganisa ezihambelanayo, okanye ii-CMM, uzinzo lwesakhiwo sisiseko somlinganiselo othembekileyo. Naluphi na utshintsho lobushushu, ukungcangcazela, okanye ukuqhekeka kwezinto ixesha elide kunokuguqulela ngokuthe ngqo ekungaqinisekini komlinganiselo.I-ceramic echanekileyo ye-CMMizicelo zijongana nale mingeni kwinqanaba lezinto eziphathekayo. Iibhulorho zeseramikhi, iindlela zokhokelo, iziseko, kunye nezinto zokwakha zigcina ijiyometri yazo ngokuhamba kwexesha, nokuba kuphantsi kobushushu obuguquguqukayo. Olu zinzo luvumela iinkqubo zeCMM ukuba zinike iziphumo zokulinganisa ezihambelanayo ngaphandle kokuhlawula kakhulu okusingqongileyo okanye ukuhlaziywa rhoqo.

Ngokungafaniyo nezakhiwo zegranite okanye zesinyithi zemveli, izinto zeseramikhi eziphambili zoshishino zibonelela ngokulinganisela okukhethekileyo kokuqina kunye nobunzima obuphantsi. Olu dibaniso luphucula ukusebenza okuguquguqukayo, okuvumela isantya sokuhlola esikhawulezayo ngelixa kugcinwa ukuchaneka kokulinganisa. Njengoko uhlolo oluzenzekelayo luqheleka ngakumbi kwiifektri ezikrelekrele, olu zinzo oluguquguqukayo luya luxabiseka ngakumbi. Iseramikhi echanekileyo kwiinkqubo zeCMM ixhasa ukuveliswa okuphezulu ngaphandle kokubeka emngciphekweni ukuthembeka kwedatha, okwenza ifaneleke kakuhle kwiindawo zanamhlanje zolawulo lomgangatho.

I-ceramic echanekileyo yokusetyenziswa kwe-photonics ijongene neemfuno ezifuna kakhulu. Iinkqubo ze-photonic zixhomekeke ekulungelelanisweni ngokuchanekileyo, uzinzo lwendlela ye-optical, kunye nokumelana nokushukuma kobushushu. Nokuba utshintsho oluncinci lobukhulu lunokuchaphazela ukulungelelaniswa kwemisebe, uzinzo lwamaza obude, okanye ukuthembeka kwesignali. Izixhobo ze-ceramic, ngakumbi i-alumina ephezulu kunye ne-silicon nitride ceramics, zibonelela ngozinzo lobushushu kunye nolwe-mechanical olufunekayo ukugcina ulungelelwaniso oluchanekileyo lwe-optical kwixesha elide lokusebenza.

Kwiinkqubo ze-laser, iibhentshi ze-optical, kunye namaqonga okulinganisa i-photonic, izakhiwo ze-ceramic zisebenza njengezixhobo ezithuleyo zokunika amandla okusebenza. I-coefficient yazo ephantsi yokwandiswa kobushushu inceda ukuqinisekisa ukuba izinto ze-optical zihlala zilungelelene nangona utshintsho lobushushu olubangelwa ziimeko zendalo okanye ukusebenza kwenkqubo. Kwangaxeshanye, iipropati zokudambisa ze-ceramics zinciphisa impembelelo yokungcangcazela, nto leyo ebalulekileyo ekulinganisweni kwe-optical okuphezulu kunye nokucutshungulwa kwe-laser.

I-Precision SiN ceramic, okanye i-silicon nitride ceramic, imele enye yezona klasi ziphambili zezixhobo ze-ceramic zoshishino ezisetyenziswa ngoku kwizixhobo ezichanekileyo. Yaziwa ngamandla ayo angaqhelekanga, ukuqina kokuqhekeka, kunye nokumelana nokutshayiswa kobushushu, i-silicon nitride idibanisa ukuqina koomatshini kunye nozinzo olubalaseleyo lobukhulu. Ezi mpawu zenzai-ceramic ye-SiN echanekileyoifanelekile ngokukodwa kwizicelo ezinomthwalo omninzi, ezikhawulezayo, okanye ezifuna ubushushu obuphezulu.

Kwizixhobo ze-metrology kunye ne-photonics,i-ceramic ye-SiN echanekileyoIzixhobo zihlala zisetyenziswa apho ukuqina nokuthembeka kubalulekile. Zigcina iimpawu zazo zoomatshini kumanqanaba obushushu abanzi kwaye ziyamelana nokuguguleka nokuba zisebenza nzima. Oku kuthembeka kwexesha elide kunciphisa iimfuno zokugcinwa kwaye kuxhasa ukusebenza okuzinzileyo kwenkqubo kulo lonke ixesha lenkonzo yesixhobo. Kubavelisi kunye nabasebenzisi bokugqibela, oku kuthetha ukuba ixabiso elipheleleyo lobunini kunye nokuzithemba okuphezulu kwiziphumo zokulinganisa.

Ngokwembono ebanzi, ukwanda kokwamkelwa kwezinto zeseramikhi zoshishino kubonisa utshintsho kwindlela eziyilwe ngayo iinkqubo zokuchaneka. Endaweni yokuhlawula imida yezinto eziphathekayo ngesoftware enzima okanye ulawulo lokusingqongileyo, iinjineli ziya zikhetha ngakumbi izinto ezixhasa ukuchaneka ngokwemvelo. Iseramikhi echanekileyo yezicelo zeCMM kunye ne-photonics imele le filosofi ngokubonelela ngozinzo, ukuqikelelwa kwangaphambili, kunye nokuqina kwinqanaba lesakhiwo.

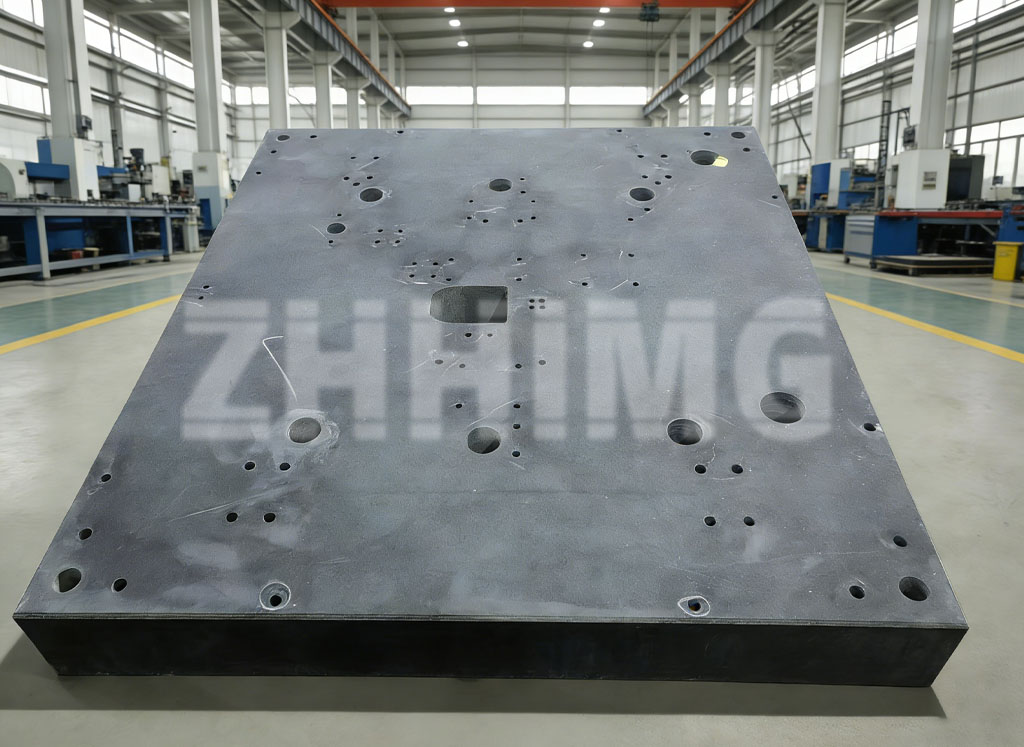

Kwi-ZHHIMG, ubunjineli be-ceramic bujongwa njengomsebenzi odibanisa isayensi yezinto eziphathekayo kunye nokuveliswa ngokuchanekileyo. Izinto ze-ceramic zoshishino aziphathwa njengezinto eziqhelekileyo, kodwa njengezinto ezibalulekileyo ezilungiselelwe ukusetyenziswa okuthile. Nokuba zisetyenziswa kwizakhiwo ze-CMM, kumaqonga e-photonics, okanye kwiinkqubo zokuhlola eziphambili, inxalenye nganye ye-ceramic yenziwe ngolawulo oluqinileyo malunga nokuthe tyaba, i-geometry, kunye nomgangatho womphezulu. Olu qwalaselo kwiinkcukacha luqinisekisa ukuba izibonelelo zezinto ezibonakalayo ziyafezekiswa ngokupheleleyo kwizicelo zehlabathi lokwenyani.

Njengoko amashishini eqhubeka efuna ukuchaneka okuphezulu, imijikelo yokulinganisa ekhawulezayo, kunye neenkqubo ze-optical ezithembekileyo, indima ye-ceramics eziphambili iya kwanda kuphela. Izisombululo ze-ceramic zoshishino, kubandakanya i-ceramic echanekileyo ye-CMM, i-ceramic echanekileyo ye-photonics, kunye nezixhobo ze-ceramic ezichanekileyo ze-SiN, azisezona teknoloji zibalulekileyo. Ziba zizinto ezisisiseko zesizukulwana esilandelayo sezixhobo ezichanekileyo.

Kwiinjineli, abayili beenkqubo, kunye nabenzi bezigqibo eYurophu naseMntla Melika, ukuqonda ixabiso lezinto zeseramikhi kubalulekile xa kucwangciswa utyalo-mali lwexesha elizayo kwi-metrology kunye ne-photonics. Ngokukhetha izisombululo zeseramikhi ezifanelekileyo kwinqanaba loyilo, kunokwenzeka ukufikelela ngokuchanekileyo okuphezulu, uzinzo olukhulu, kunye nobomi benkonzo ende—iziphumo ezixhasa ngokuthe ngqo umgangatho, ukusebenza kakuhle, kunye nokukhuphisana kwexesha elide kwimveliso ephucukileyo.

Ixesha leposi: Jan-13-2026