Ukulinganisa ngokuchanekileyo bekusoloko kuyinto ebalulekileyo kwimveliso ephucukileyo, kodwa ulindelo olubekwe kwiinkqubo zokuhlola zanamhlanje lutshintsha ngokukhawuleza. Njengoko ubungakanani bemveliso bukhula, ijiyometri yemveliso iba nzima ngakumbi, kwaye iimfuno zokunyamezela ziyaqina, iindlela zokuhlola zendabuko azisanele. Olu tshintsho lubeke umatshini wokulinganisa olungelelanisiweyo kwi-metrology embindini wezicwangciso zokuqinisekisa umgangatho kuzo zonke izimboni zeenqwelo-moya, iimoto, izixhobo ze-elektroniki, kunye nobunjineli bokuchaneka.

Namhlanje, i-metrology ayisapheleli nje kumagumbi okuhlola angashukumiyo okanye kumasebe omgangatho ozimeleyo. Ibe yinxalenye edibeneyo yeenkqubo zokuvelisa ezikrelekrele, eziqhutywa kukuzisebenzela ngokuzenzekelayo, ulawulo lwedijithali, kunye noqhagamshelo lwedatha. Kule meko, ubuchwepheshe obufana ne-CMM yerobhothi, umatshini wokulinganisa olawulwa yikhompyutha, kunye nezisombululo zokuhlola eziphathwayo zichaza ngokutsha indlela kunye nendawo yokulinganisa eyenziwa ngayo.

Ingcamango yerobhothi i-CMM ibonisa indlela ebanzi yokwenziwa kwezinto ngokuzenzekelayo kunye nokuguquguquka kokulinganisa. Ngokudibanisa intshukumo yerobhothi kunye netekhnoloji yokulinganisa ehambelanayo, abavelisi banokufikelela kwimveliso ephezulu ngelixa begcina ukuchaneka kokuhlolwa okuqhubekayo.Iinkqubo zeRobhothizibaluleke kakhulu kwiindawo zemveliso apho imisebenzi yokulinganisa ephindaphindwayo kufuneka yenziwe ngokuthembekileyo kwaye ngaphandle kokungenelela okuncinci komntu. Xa zidityaniswe ngokufanelekileyo, izisombululo ze-CMM ezisekwe kwirobhothi zixhasa ukuhlolwa okucwangcisiweyo, impendulo ekhawulezileyo, kunye namaxesha okujikeleza ancitshisiweyo, konke oku kuncedisa ngokuthe ngqo ekuphuculeni ulawulo lwenkqubo.

Eyona nto iphambili kwezi zisombululo zenzekelayo kulapho kukho umatshini wokulinganisa olawulwa yikhompyutha. Ngokungafaniyo neenkqubo ezisetyenziswa ngesandla, umatshini wokulinganisa olawulwa yikhompyutha wenza iinkqubo zokulinganisa ezicwangcisiweyo ezinokuphindaphindwa okuphezulu kunye nokulandeleka. Iindlela zokulinganisa, amaqhinga okuphanda, kunye nohlalutyo lwedatha zonke zilawulwa yisoftware, ziqinisekisa iziphumo ezihambelanayo kuzo zonke iinguqu, abaqhubi, kunye neebhetshi zemveliso. Eli nqanaba lolawulo libalulekile kubavelisi abasebenza phantsi kwemigangatho yamazwe ngamazwe engqongqo kunye neemfuno zomgangatho ezithile kubathengi.

Umdla okhulayo kwi-CNC CMM yokuthengiswa kwiimarike zehlabathi ubonakalisa le mfuno yokwenza izinto ngokuzenzekelayo kunye nokuthembeka. Abathengi abasajongi kuphela iinkcukacha zokuchaneka; bavavanya uzinzo lwenkqubo, ukusebenza kwexesha elide, ukuhambelana kwesoftware, kunye nokulula kokuhlanganiswa kwimigca yemveliso ekhoyo. I-CNC CMM imele utyalo-mali ekusebenzeni kakuhle kwenkqubo kunye nokukwazi ukulinganisa, ngakumbi xa idibene nezinto eziqinileyo zokwakha kunye nezixhobo ezisisiseko ezizinzileyo.

Nangona kukho ukwanda kweenkqubo ezizenzekelayo ngokupheleleyo, ukuguquguquka kuhlala kuyinto ephambili ekuqwalaselweni kwi-metrology yanamhlanje. Kulapho izisombululo ezifana nengalo ephathwayo ye-CMM zidlala indima ebalulekileyo khona. Iingalo zokulinganisa eziphathekayo zivumela abahloli ukuba bazise inkqubo yokulinganisa ngqo kwindawo leyo, endaweni yokuthutha izinto ezinkulu okanye ezibuthathaka kwi-CMM esisigxina. Kwizicelo ezibandakanya iindibano ezinkulu, ukuhlolwa kwindawo, okanye inkonzo yasentsimini, iingalo eziphathwayo zibonelela ngamandla okulinganisa asebenzayo ngaphandle kokulahlekelwa ngokuchanekileyo.

Ngaphakathi komatshini wokulinganisa obanzi kwi-metrology landscape, ezi nkqubo ziphathwayo ziyahambelana endaweni yokutshintsha ii-CMM zendabuko zohlobo lwebhulorho kunye nee-gantry. Isisombululo ngasinye sisebenza injongo ethile, kwaye amaqhinga omgangatho wanamhlanje adla ngokubandakanya indibaniselwano yeenkqubo zokulinganisa ezizinzileyo, eziphathwayo, kunye nezizenzekelayo. Umngeni usekuqinisekiseni ukuba yonke idatha yokulinganisa ihlala ihambelana, inokulandeleka, kwaye ihambelana nemigangatho yomgangatho weshishini.

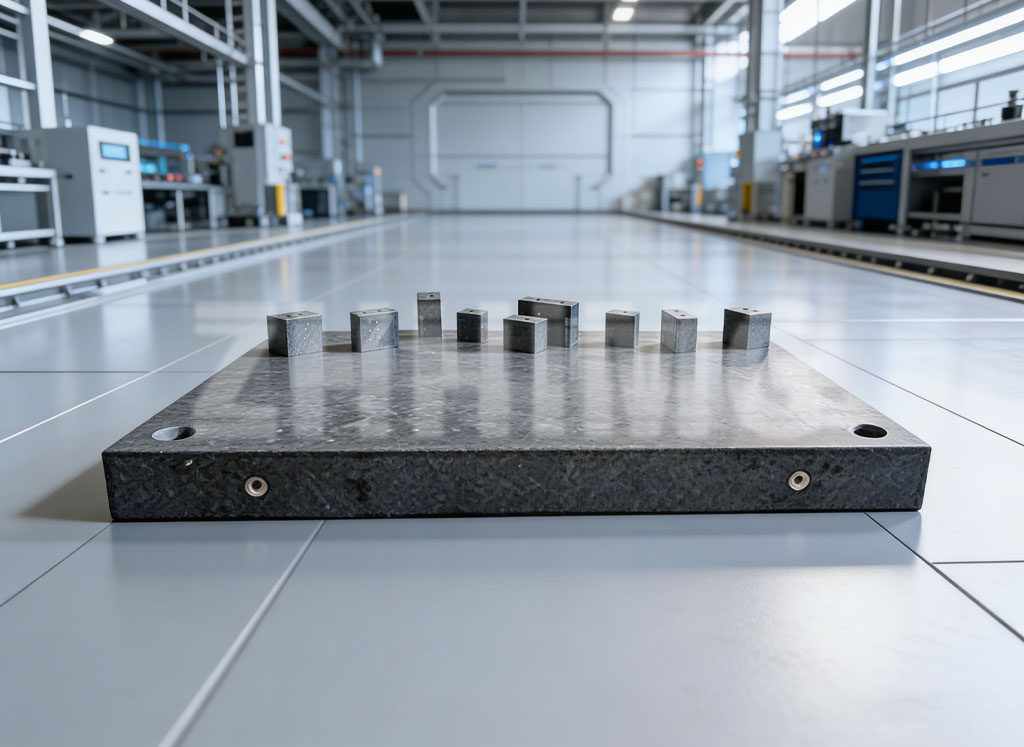

Uzinzo lolwakhiwo luhlala luyimfuneko esisiseko nokuba luluphi na ulungelelwaniso olukhethiweyo lweCMM. Nokuba ixhasa i-robot CMM, inkqubo yokuhlola i-CNC, okanye iseli yokulinganisa ye-hybrid, isiseko soomatshini sinefuthe ngqo ekuthembekeni kokulinganisa. Izinto ezifana ne-precision granite zisetyenziswa kakhulu kwiziseko zeCMM kunye nezinto zokwakha ngenxa yokwanda kwazo okuphantsi kobushushu, ukuxinana okugqwesileyo kokungcangcazela, kunye nozinzo lwexesha elide. Ezi mpawu zibaluleke kakhulu kwiimashini zokulinganisa ezizenzekelayo nezilawulwa yikhompyutha, apho nokuba ukushukuma okuncinci kolwakhiwo kunokuchaphazela iziphumo zokulinganisa ngokuhamba kwexesha.

Iqela le-ZHONGHUI (ZHHIMG) lixhase ixesha elide ishishini le-metrology yehlabathi ngokubonelela ngezinto ze-granite ezichanekileyo kunye nezisombululo zesakhiwo kwiinkqubo zokulinganisa eziphambili. Ngamava amaninzi kwimveliso echanekileyo kakhulu, i-ZHHIMG isebenzisana ngokusondeleyo nabavelisi be-CMM, abahlanganisi be-automation, kunye nabasebenzisi bokugqibela ukuhambisaiziseko zegranite ezenziwe ngokwezifiso, iindlela zokubonisa, kunye nezakhiwo zoomatshini ezenzelwe iimeko zokulinganisa ezifuna umgudu. Ezi zixhobo zisetyenziswa kakhulu ekufakweni kwe-robot CMM, kwiinkqubo zokulinganisa ze-CNC, kunye namaqonga okuhlola axutyiweyo.

Njengoko imveliso yedijithali iqhubeka nokukhula, iinkqubo zokulinganisa zinxulunyaniswa ngakumbi neenkqubo zokuphumeza imveliso, amaqonga olawulo lweenkqubo zezibalo, kunye namawele edijithali. Kule meko, indima yomatshini wokulinganisa olungelelanisiweyo kwi-metrology idlula ngaphaya kokuhlolwa ukuze ibe ngumthombo wobukrelekrele benkqubo ngexesha langempela. Ukuqokelelwa kwedatha ngokuzenzekelayo, uhlalutyo, kunye nempendulo kuvumela abavelisi ukuba babone ukuphambuka kwangethuba kwaye baphucule iiparameter zemveliso ngokukhawuleza.

Ikamva le-metrology liza kubunjwa kukuzisebenzela okukhulu, ukunyuka kokuhamba, kunye nolindelo oluphezulu lokuchaneka nokusebenza kakuhle. Iinkqubo ze-CMM zerobhothi ziya kuqhubeka nokwandisa ubukho bazo kwimigangatho yemveliso, ngelixa iingalo eziphathekayo kunye noomatshini bokulinganisa abalawulwa yikhompyutha baya kuxhasa amaqhinga okuhlola aguquguqukayo nawahlukeneyo. Kuyo yonke le meko iguqukayo, ukubaluleka kwezakhiwo ezizinzileyo, ulawulo oluchanekileyo lokuhamba, kunye nezixhobo ezinokuthenjwa akukatshintshi.

Kubavelisi abavavanya izisombululo ezintsha zokuhlola okanye abaphonononga iindlela zokuthengisa ze-CNC CMM, imbono yenqanaba lenkqubo ibalulekile. Iinkcukacha zokuchaneka zodwa azichazi ukusebenza. Uzinzo lwexesha elide, ukuguquguquka kwendalo, kunye nokuthembeka kwesakhiwo kubaluleke ngokulinganayo ekufezekiseni iziphumo zokulinganisa ezihambelanayo.

Njengoko amashishini esiya kwiindawo zemveliso ezikrelekrele neziqhagamshelwe ngakumbi, oomatshini bokulinganisa abadibeneyo baya kuhlala besisiseko se-metrology yanamhlanje. Ngokudityaniswa okucwangcisiweyo kweerobhothi, ulawulo lwekhompyutha, kunye nezakhiwo ezicwangciswe ngokuchanekileyo, iinkqubo zokulinganisa zanamhlanje azigcini nje ngokuhambelana nokuvelisa izinto ezintsha kodwa ziyenza isebenze.

Ixesha leposi: Jan-06-2026