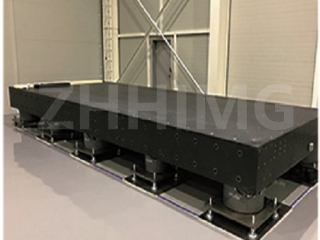

Ukusetyenziswa kwezinto zegranite kwiCoordinate Measuring Machines (CMM) yindlela eqhelekileyo kwishishini lokuvelisa. Igranite lilitye elivela ngokwemvelo elineempawu ezintle ezifana nokuzinza kobushushu, i-coefficient ephantsi yokwanda kobushushu, kunye nokuqina okuphezulu. Ezi mpawu zenza ukuba ibe yinto efanelekileyo yokusetyenziswa ekwenzeni izixhobo zokulinganisa ezinobuthathaka ezifana neeCMM. Ezi mpawu ziqinisekisa ukuchaneka kokulinganisa okuphezulu okubalulekileyo kwishishini lokuvelisa.

Uzinzo lobushushu yenye yezona mpawu zibalulekileyo zegranite. Ii-CMM zizixhobo ezichanekileyo ekufuneka zizinzile nokuba kukho ukuguquguquka kobushushu. Ukusetyenziswa kwegranite njengezinto zokwakha kuqinisekisa ukuba umatshini uhlala uzinzile, nokuba ubushushu butshintsha. I-coefficient yokwandiswa kobushushu begranite iphantsi, nto leyo eqinisekisa ukuba naluphi na ulwandiso lobushushu luncinci, nto leyo evumela ukuba imilinganiselo ihlale ihambelana kuluhlu olubanzi lobushushu bokusebenza. Olu phawu lubalulekile ekuchanekeni kwemilinganiselo eyenziwe yi-CMMs.

I-coefficient ephantsi yokwandiswa kobushushu begranite iqinisekisa ukuba imilinganiselo ethathwe yi-CMMs ihlala ichanekile nokuba kukho utshintsho kubushushu. Utshintsho kubushushu lunokuchaphazela ubungakanani kunye nokuma kwezinto ezilinganiswayo. Nangona kunjalo, ukusetyenziswa kwegranite njengesixhobo sokwakha se-CMMs kuqinisekisa ukuba naluphi na utshintsho kubushushu aluchaphazeli ukuchaneka kokulinganisa. Le propati ibalulekile kwishishini lokuvelisa, apho ukuchaneka kubalulekile ekuqinisekiseni ukuba iimveliso ezigqityiweyo ziyahlangabezana neemfuno zabathengi.

Ukuqina okuphezulu yenye impawu ebalulekileyo eyenza i-granite ibe yinto efanelekileyo kwi-CMMs. Izinto ezisetyenziswa kwi-CMMs kufuneka ziqine ukuze zixhase into yokulinganisa, edla ngokuba yi-probe ebukhali. Ukusetyenziswa kwe-granite kuqinisekisa ukuba umatshini uhlala uqinile, kunciphisa naluphi na utshintsho olubangelwa bubunzima bento yokulinganisa. Le mpawu iqinisekisa ukuba i-probe yokulinganisa ihamba ngokuchanekileyo kwii-axes ezintathu (x, y, kunye no-z) ezifunekayo ukuze kuthathwe imilinganiselo ngokuchanekileyo.

Ukusetyenziswa kwegranite ekwakhiweni kweCMM kuqinisekisa ukuba umatshini uhlala uzinzile ixesha elide. Igranite yinto eqinileyo, eqinileyo engagobiyo, engagobiyo, okanye ehle ngokuhamba kwexesha. Ezi mpawu ziqinisekisa ukuba umatshini uya kugcina ukuchaneka kwawo kunye nokuchaneka kwawo kwiminyaka emininzi yokusebenza. Ukongeza, igranite ayigugi, nto leyo ethetha ukuba ayifuni ukulungiswa kakhulu, inciphisa ixesha lokungasebenzi kwaye yonyusa ixesha elide lomatshini.

Ukuqukumbela, ukusetyenziswa kwegranite ekwakhiweni kweCMM kubalulekile ekuqinisekiseni ukuchaneka okuphezulu kokulinganisa kwishishini lokuvelisa. Iimpawu ezikhethekileyo zegranite, ezinje ngokuzinza kobushushu, i-coefficient ephantsi yokwanda kobushushu, kunye nokuqina okuphezulu, ziqinisekisa ukuba umatshini uhlala uchanekile nokuba kukho ukuguquguquka kobushushu. Ukongeza, ukuqina kwegranite kunye nokumelana nokuguguleka kuqinisekisa ukuba umatshini ugcina ukuchaneka kwawo kwiminyaka emininzi yokusebenza. Lilonke, ukusetyenziswa kwegranite kwiCMMs lutyalo-mali olulumkileyo ekuqinisekiseni imveliso kunye nomgangatho kwishishini lokuvelisa.

Ixesha lokuthumela: Epreli-09-2024