Iziseko zegranite zizinto ezibalulekileyo kwiimashini ze-CNC (Computer Numerical Control).

Ezi ziseko zibonelela ngesiseko esizinzileyo sesixhobo somatshini, esibalulekileyo ekuchanekeni nasekuchanekeni ngexesha lenkqubo yokuvelisa. Ke ngoko, ubungakanani kunye nemilo yesiseko segranite kufuneka zilungelelanise neemfuno ezahlukeneyo zesixhobo somatshini se-CNC.

Abavelisi boomatshini be-CNC basebenzisa iintlobo ezahlukeneyo zezinto zokwakha isiseko, kodwa i-granite yeyona ikhethwa kakhulu ngenxa yokuba ineempawu zokuxinana okuphezulu kunye nokungcangcazela okuphantsi. I-granite yinto efanelekileyo kwiziseko zoomatshini njengoko inokugcina imo yayo phantsi kweemeko ezinzima, kubandakanya amaqondo obushushu aphezulu kunye noxinzelelo oluqhubekayo loomatshini.

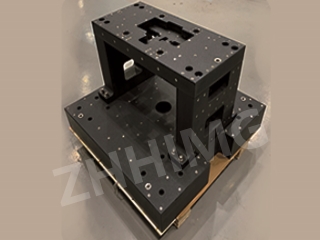

Abavelisi boomatshini be-CNC banikezela ngoluhlu lweesayizi kunye neemilo zesiseko segranite, ezinokuhluka ngokuxhomekeke kubukhulu kunye nobunzima bomatshini. Kwiimashini ezinkulu ze-CNC, isiseko sinokuthatha imo yebhokisi engxande okanye uyilo olufana no-T. Olu yilo lubonelela ngozinzo oluphezulu kunye nokuqina kwaye luyimfuneko kwiinkqubo zokusika ezinzima.

Ngokwahlukileyo koko, oomatshini abancinci be-CNC baya kufuna isiseko segranite esincinci. Imilo yesiseko inokwahluka, kuxhomekeke kwimilo kunye nobukhulu bomatshini. Oomatshini abancinci banokufuna isiseko esibuxande okanye esisikwere, esiya kubonelela ngozinzo olufanelekileyo kunye nokuqina kokucubungula iindawo ezincinci ukuya kweziphakathi.

Kubalulekile ukuqaphela ukuba ubungakanani besiseko kunye nemilo kufuneka kuqwalaselwe ngononophelo xa kuyilwa umatshini we-CNC. Uyilo lomatshini luya kumisela uhlobo lwenkqubo yokuvelisa, ubungakanani kunye nobunzima bezinto ezicutshungulwayo, kunye nokunyamezelana okufunekayo. Ezi zinto ziya kumisela ubungakanani kunye nemilo yesiseko somatshini.

Enye inzuzo yesiseko segranite kukukwazi kwayo ukuthomalalisa ukungcangcazela okunokwenzeka ngexesha lokusebenza komatshini. Igranite inomlinganiselo ophantsi wokwandiswa kobushushu, oko kuthetha ukuba ayizukunwebeka okanye inciphe kakhulu ngenxa yotshintsho lobushushu, nto leyo eqinisekisa ukuchaneka komatshini.

Amandla esiseko segranite nawo abalulekile ekuxhaseni iindawo ezihambayo zomatshini. Ngoko ke, igranite kufuneka ibe semgangathweni ophezulu, ingabi nazimfanta, kwaye imelane nokuguga.

Ukuqukumbela, ubungakanani kunye nemilo yesiseko segranite kufuneka ivumelane neemfuno ezahlukeneyo zesixhobo somatshini se-CNC. Uyilo lomatshini luya kugqiba ubungakanani kunye nemilo yesiseko esifunekayo kuso. Ke ngoko, abavelisi kufuneka baqwalasele uhlobo lomsebenzi umatshini we-CNC oza kuwenza, ubunzima kunye nobukhulu bezinto ezicutshungulwayo, ukuchaneka kunye nokuchaneka okufunekayo, kunye nenqanaba lokungcangcazela okuveliswayo ngexesha lenkqubo ukuqinisekisa isiseko esizinzileyo sesixhobo somatshini. Ekugqibeleni, isiseko segranite esifanelekileyo siya kunceda ekuboneleleni ngokusebenza komatshini okuphuculweyo kunye nokuchaneka kunye nokuchaneka okukhulu okunokunceda amashishini amaninzi axhomekeke kumatshini we-CNC.

Ixesha leposi: Matshi-26-2024